Operating instructions

W3G630-GR85-01

Translation of the original operating instructions

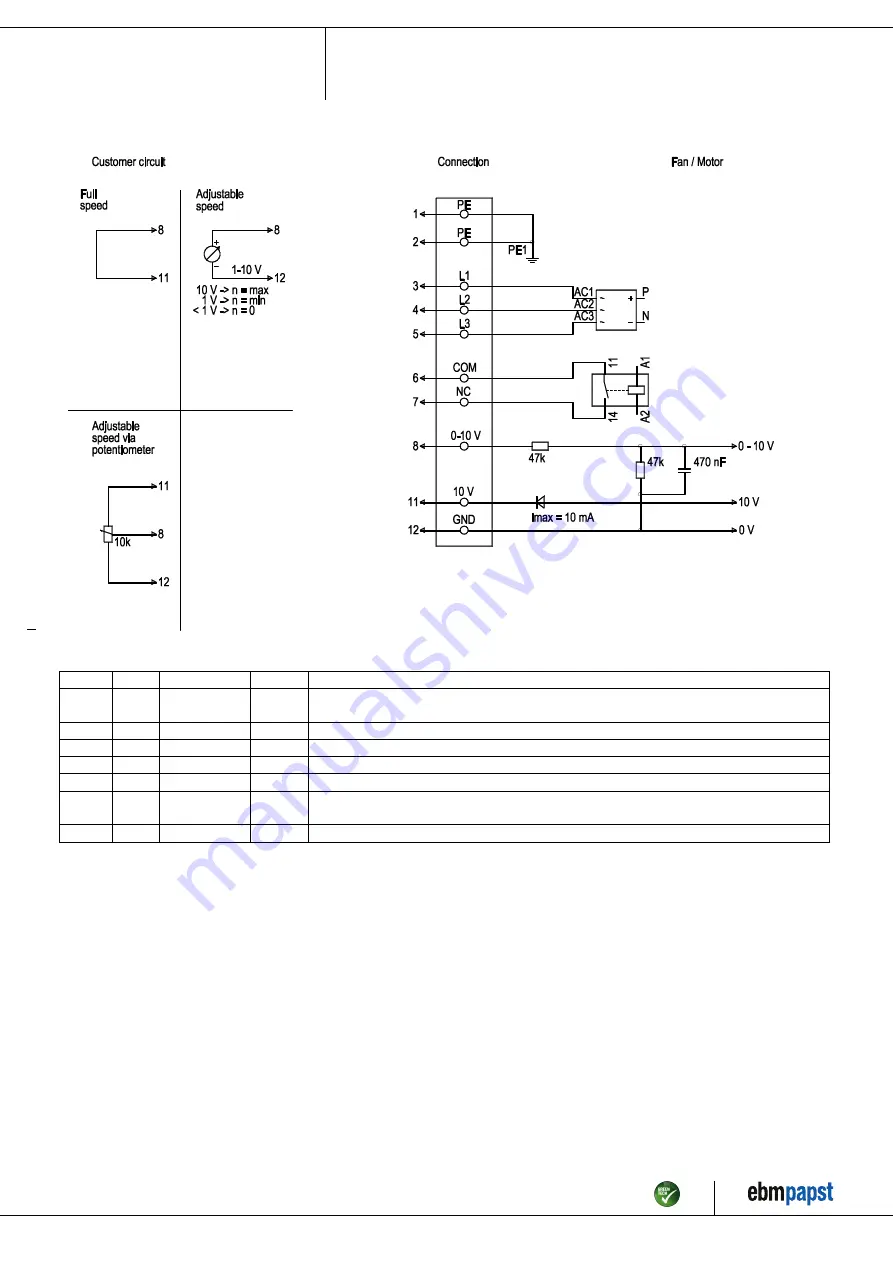

4.5 Connection diagram

Drawing preliminary!

No.

Conn.

Designation

Color

Function/assignment

1

1, 2

PE

green/

yellow

Protective earth

1

3, 4, 5

L1, L2, L3

black

Power supply 50 / 60 Hz

1

6

COM

white 1

Floating status contact, break for failure (2A, max. 250 VAC, min. 10 mA, AC1)

1

7

NC

white 2

Floating status contact, break for failure

2

8

0 - 10 V

yellow

Control input, set value 0-10 VDC, impedance 100 kOhm, SELV

2

11

+ 10 V

red

Voltage output 10 VDC (±3%), max. 10 mA, power supply for external devices (e.g.

potentiometers), SELV

2

12

GND

blue

Reference ground for control interface, SELV

Item no. 50329-5-9970 · ENU · Change 205336 · Approved 2020-07-16 · Page 9 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com