User Manual VW 1350 HB

– The Manual Operated VMS-Trailer

2 GENERAL SPECIFICATIONS

2.1 DESCRIPTION OF THE MACHINE

This machine is a portable object that will be used by road incidents,

roadworks and diversions. The work areas of this machine are

highways,

state

roads

and

inner

city

urban

areas.

2.2 TECHNICAL SPECIFICATIONS

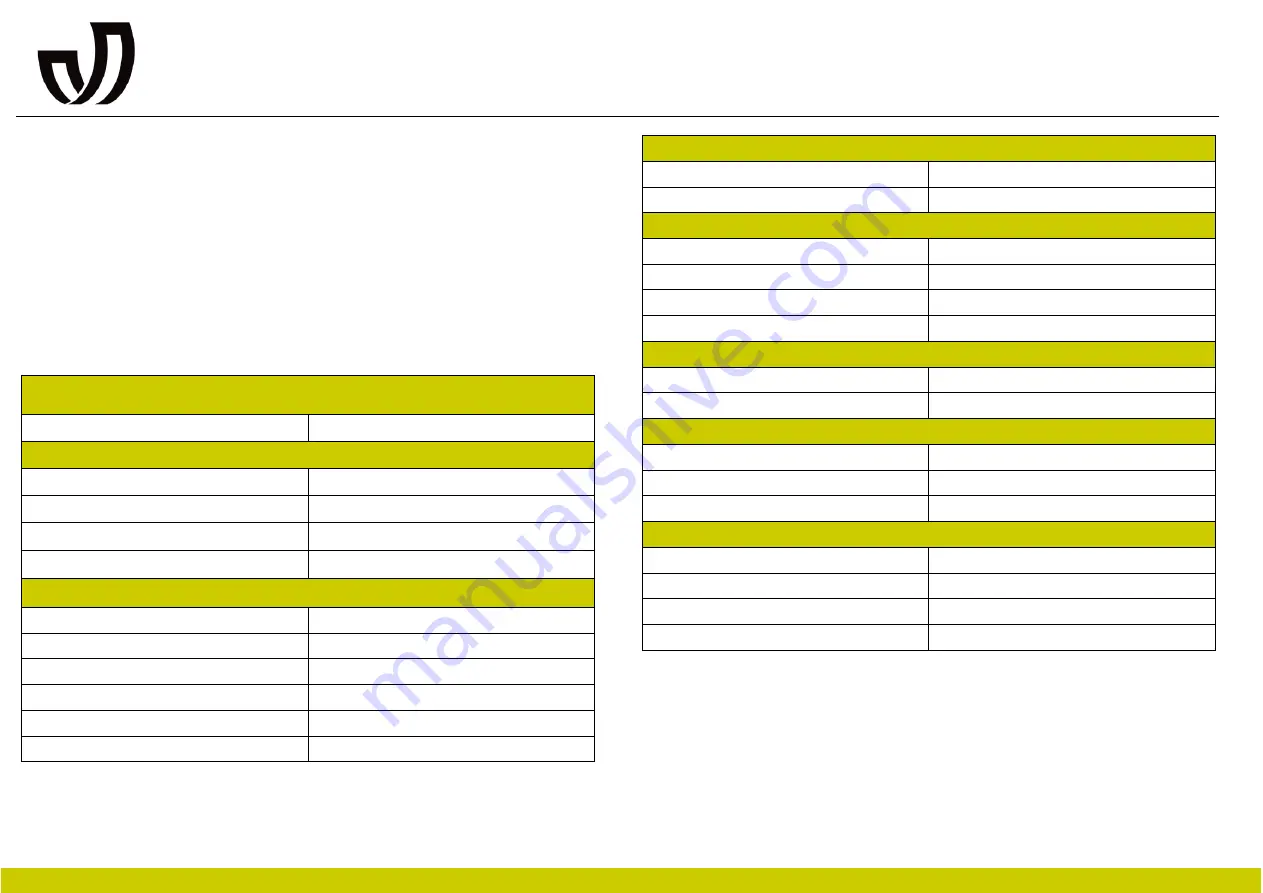

Technical specifications VW 1350 HB

Underframe

Axle

WAP

– WAG 135B 1.350KG

Overrun

WAP 24 / 35.1

– 2.000KG

Brakes

Drum Brakes

Tires

195/50 R13

Electrical system

Voltage

24 Volt

Batteries

4 x (standard semi-traction)

Battery capacity

230 Ah (standard)

Battery charger

230 Volt / 40 Amp.

Solar panels

2 x (standard)

Maximum power solar panel

200 Watt per piece

Driving lights

Lighting

12 Volt (standard)

Connector

13-pin connector (standard)

Hydraulic system

Upper-frame

Hydraulic executed

Emergency service

By-pass on hydro unit

Hydro unit

800 Watt

Hydraulic oil

Tellus 15

Upper-frame

Reflection

Class 2 red / white

Under plate

Signface J37 (standard)

Display

Display

80*80 mm Swarco Futurit

Voltage

24 Volt

Maximum power

240 Watt

Other components

Extendible supports

4 x, manual

Nose wheel

Manual

Storage unit Andreas stripes

3 x (2000*225*30 mm)

Storage support plates

4 x (400*400*40 mm)

Chart 1