12

EP100 Master Instruction

_____________________________________________________

D00002-C-04

7 START-UP

7.1 General

First of all, the nameplate should be checked,

especially with respect to references to Ex / non- Ex,

input signal, single / double acting.

Before starting the positioner the EP100 has to be

mounted to the actuator; an input signal 4 to 20 mA or

split range have to be available. The supply air

connection must have sufficient capacity and

pressure of 1.4 to 6 bar (20 to 90 psig) and should not

exceed the maximum operating pressure of the

actuator.

The EP100 can be adjusted by means of switches

and potentiometers when the housing cover is

opened.

Attention:

Configuration using switches and

potentiometers may interfere with operation of the

actual process! During configuration it is

recommended that there is no flow through the

valve.

At initial start-up various adjustments have to be set.

The following procedure is recommended:

Setting of

direction of rotation

of feedback lever

(chapter 7.2)

Setting of

input signal range

e.g. 4 to 20 mA or

split range (chapter 7.3)

Setting of

gain

(chapter 7.4)

Setting of

zero and span

(chapter 7.5)

Setting of

damping

(time constant, chapter 7.6)

The

position indicator

12 is attached to the

desired position after selection of the

transmission at indicator shaft (chapter 7.7)

The

air capacity throttles

at the pneumatic

output (screws 17 and 18 underneath of the

SERVICE openings) are factory-set to the

operating value and are normally not reset

(exception see chapter 7.8).

When attaching the

housing cover

make sure

that the venting opening points to the bottom

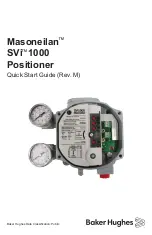

Settings via switches and potentiometers

For the setting of the EP100 and the adjustment of

various parameters 8 dip switches and 5

potentiometers are available.

See electronics imprint as follows:

1) Adjustment of electronic board (in workshop, see page 17)

The potentiometers are for the setting of:

Zero point (ZERO): P3

Span (S): P2

Gain (G): P4

Damping (D): P5

Electronics alignment: P1

1)

Single-threaded potentiometers with limited rotation angle to

set gain (G) and damping (D) are available, where the actual

position is indicated by an arrow. To set zero point (ZERO),

span (S) and the electronics alignment

1)

multiplethreaded

potentiometers (approx. 30 rotations) without rotation

limitation are used.

The

switches

are for the setting of:

Direction of rotation of feedback lever (switches 1, 2)

Electronics adjustment (switch 3)

1)

Signal range (switches 4, 5, 6 and 7)

Pneumatic test (switch 8)

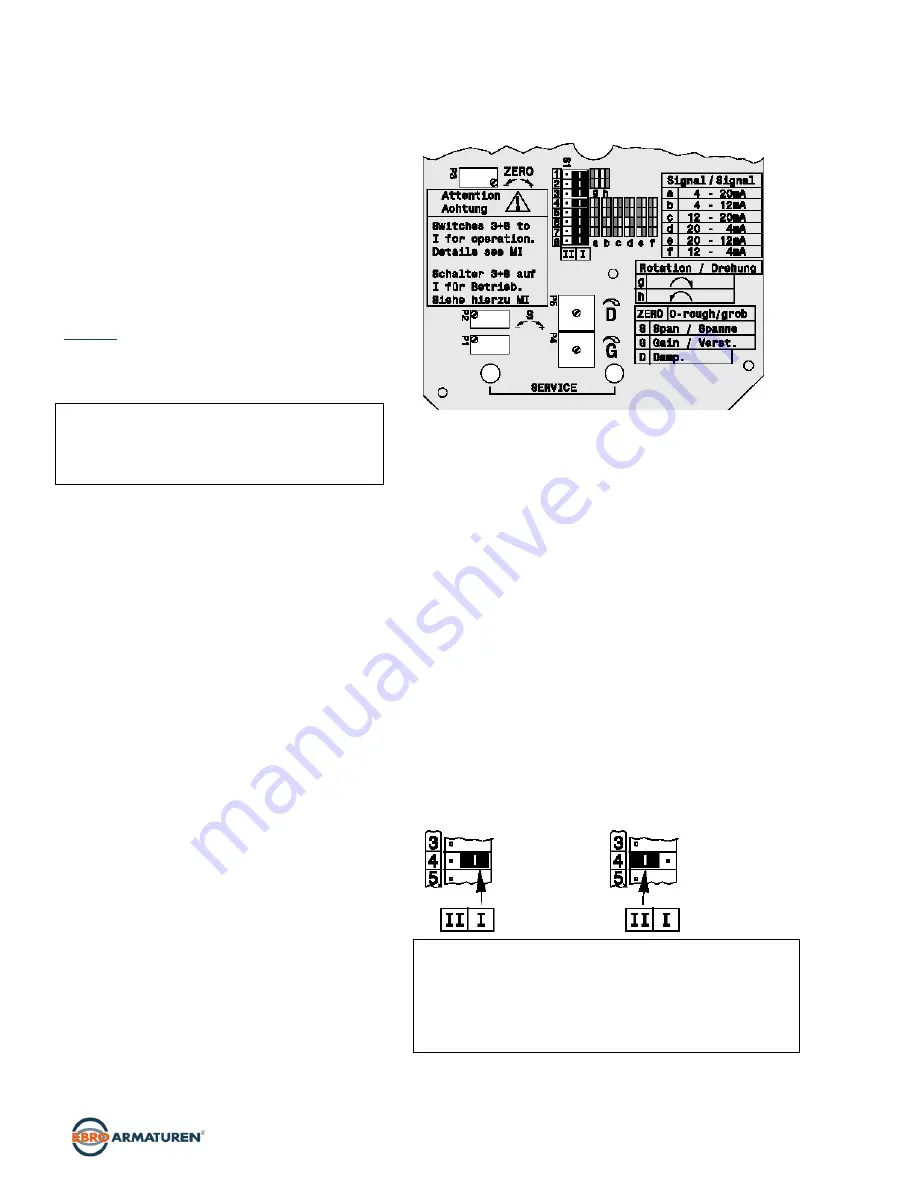

The switch numbers (1 through 8) are imprinted on the

electronics. The possible switch position (“I” and “II”) are

imprinted below switch 8. The switch positions are defined as

follows:

Switch Position

“I”:

Switch Position II:

Caution!

Switches 3 and 8 must be during operation in position “I”.

Prior to resetting switches 1 to 8 it is recommended to shut-

off the respective part of the installation since processes are

activated influencing and disturbing the current process.

Therefore, it is recommended that no medium flows through

the valve during configuration..