Chengdu Ebyte Electronic Technology Co., Ltd.

Copyright ©2012–2018, Chengdu Ebyte Electronic Technology Co.,Ltd.

9

Please make sure anti-static measures are taken when installing and using, high frequency devices have electrostatic

susceptibility.

Please ensure the humidity is within limited range for some parts are sensitive to humidity.

Please avoid using modules under too high or too low temperature.

5.3 High bit error rate

There are co-channel signal interference nearby, keep away from interference sources or modify frequency, channel

to avoid interference.

The clock waveform on the SPI is not standard. Check whether there is interference on the SPI line. The SPI bus

line should not be too long.

Unsatisfactory power supply may also cause garbled characters, and ensure the reliability of the power supply.

If the extension cable or feeder is of poor quality or too long, the bit error rate will be high.

6. Welding operation guidance

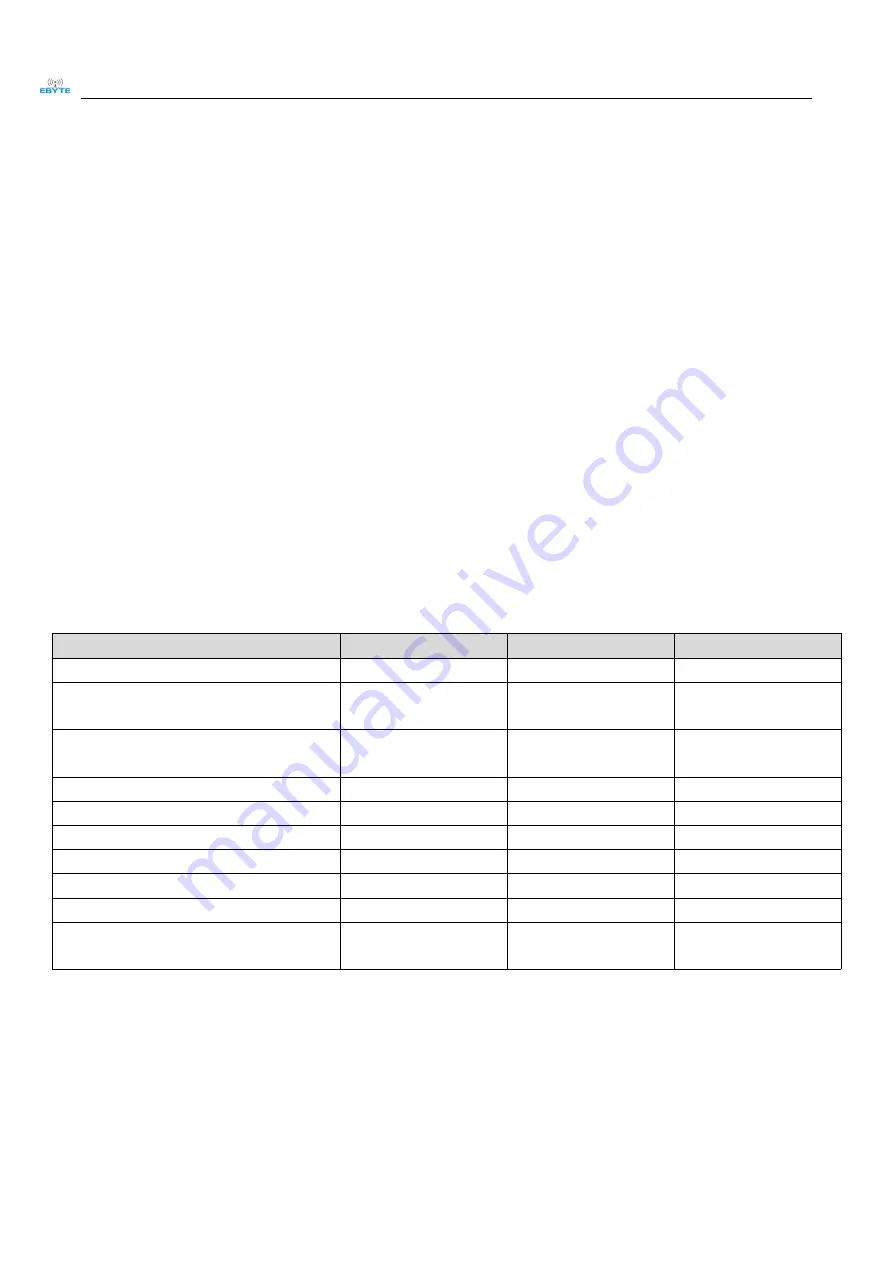

6.1 Reflow Soldering Temperature

Profile Feature

Curve feature

Sn-Pb Assembly

Pb-Free Assembly

Solder Paste

Solder paste

Sn63/Pb37

Sn96.5/Ag3/Cu0.5

Preheat Temperature min

(

Tsmin

)

Minimum preheating

temperature

100

℃

150

℃

Preheat temperature max (Tsmax)

Maximum

preheating

temperature

150

℃

200

℃

Preheat Time (Tsmin to Tsmax)(ts)

Preheating time

60-120 sec

60-120 sec

Average ramp-up rate(Tsmax to Tp)

Average rising rate

3

℃

/second max

3

℃

/second max

Liquidous Temperature (TL)

Liquid phase temperature

183

℃

217

℃

Time

(

tL

)

Maintained Above

(

TL

)

Time above liquidus

60-90 sec

30-90 sec

Peak temperature

(

Tp

)

Peak temperature

220-235

℃

230-250

℃

Aveage ramp-down rate

(

Tp to Tsmax

)

Average descent rate

6

℃

/second max

6

℃

/second max

Time 25℃ to peak temperature

Time of 25 ° C to peak

temperature

6 minutes max

8 minutes max