7

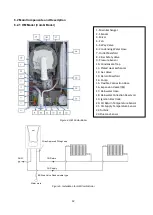

3.2 Water Systems & Gas Supply Line

Before installation of the boiler, the water systems (CH & DHW circuit) and gas supply line must be

completed in accordance with the relevant regulations and standards by installer.

Installation for gas supply pipes must be fitted according to BS6891 for GB and I.S.813.2002 for IE.

3.3 Gas Type Conversion

The standard gas type of boiler is Natural Gas. In case of a demanding gas type conversion, this is

made with charge.

Gas type conversion must be performed by the gas safe engineer. Gas leak test must be made after

the conversion operation.

Gas conversion label that indicates boiler is converted from NG to LPG must be placed on the boiler

after gas type conversion.

3.4 Installation

The boiler must be installed in accordance with national and local requirements, gas safety regulations,

relevant standarts and this manual by gas safe engineer.

The boiler must be mounted against a closed wall.

The boiler can not be positioned having direct contact to steam, detergent or gases.

Any change of flue position must not be made without consulting gas safe engineer.

Sunlight can cause color change on the exterior of your boiler over time.

The boiler must be installed in indoor spaces under normal conditions. However, it can be operated in

a suitable cabinet in places such as garage, open balcony. Please consult E.C.A for proper cabine sizes.

If boiler is located in an unheated area, it must be connected to mains, switched on, and pressure of

installation should be within operation range so that freeze protection would be activated. Even if boiler is

OFF position, freeze protection stays activated.

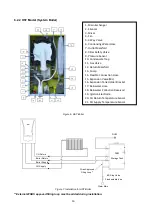

3.5 Boiler Start Up

Boiler start up must be performed certainly by gas safe engineer.

Gas Type (Natural Gas / LPG), gas supply pressure (mbar), maximum DHW operating water pressure

(bar) and electricity supply voltage on the information plate must be suitable with mains supply conditions.

This is checked by gas safe engineer.

After boiler start up, you should request information about operating the boiler and safety precautions

from gas safe engineer.

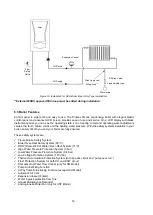

3.6 Usage and Maintenance

Read carefully instructions and precautions in this manual against wrong usage which causes unsafe

conditions.

The boiler should be checked and serviced for general maintenance once a year. Maintenance and

service operations must be carried out only gas safe engineer.

Only a damp cloth should be used for cleaning the outer surface of the boiler and then the surfaces

should be dried completely. Do not use chemical substances or solutions which cause rust and scratches

in your boiler.

CAUTION:

This boiler is not intended for use by persons (including children) who are low

physical or sensory and mental capacity and inexperienced persons without informing and

supervising the use of the boiler by responsible persons. Ensure that children under 8 years

do not play with the boiler.