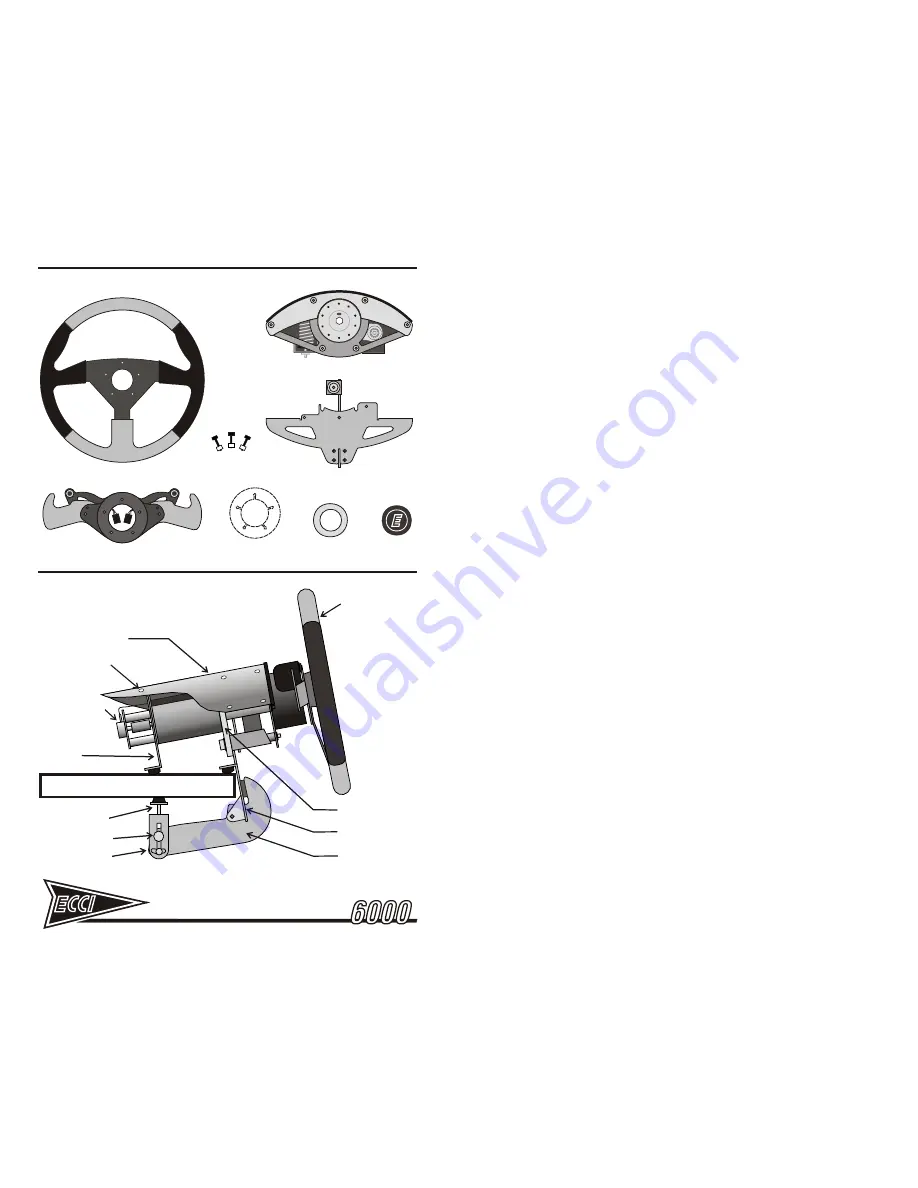

STEERING WHEEL

TRACKSTAR

SHIFT PADDLE SET

BUTTON

CENTER

RETAINING RING

BUTTON

Figure 1 - WHEEL UNIT COMPONENTS

STEERING UNIT CHASSIS

TABLE MOUNTING BRACKET

Figure 2 - WHEEL UNIT ASSEMBLY

STEERING WHEEL

TABLE MOUNTING

BRACKET

CENTRAL CHASSIS

STRUCTURAL PLATE

BRACKET

TENSIONING BOLT

TENSIONING PIVOT

TABLE MOUNTING

ARM

PIVOT SET SCREW

WHEEL UNIT HOUSING

POTENTIOMETER

HOUSING SCREWS

REAR LEG

TABLE BRACKET

SCREWS & NUTS

WHEEL SPACER

(OPTIONAL)

1.0

WHEEL UNIT SETUP AND ADJUSTMENT

1.1

UNPACKING THE WHEEL UNIT

Before unpacking and setting up your driving system, prepare a clean area with

adequate room for laying out the components. Review the list of wheel unit parts

[Figure 1] and verify that everything is present to complete assembly.

ECCI recommends keeping the original box and packing materials in case the

unit needs to be shipped in the future. If shipping is needed, the unit MUST be

shipped partially disassembled as originally received, or damage will result.

1.2

WHEEL MOUNTING BRACKET

Before starting, examine Figure 2 for how the wheel unit should appear when

assembled. In a sufficient workspace lay out the mounting bracket assembly,

steering wheel, shift paddle set, center logo button, and button retaining ring.

1. Set the main steering chassis on a table upside down on a terry cloth towel

or other soft non-abrasive cushioning material to avoid scratching the cover.

2. Using a 3/16 inch hex wrench, loosen the two center-most chassis tube bolts

[Figure 3]. Do not remove them; back them out until the nuts between the

bolt tubes and the gray central structural plate can be removed and

discarded. Then re-install the two bolts about one turn and leave them loose.

3. Invert the table bracket assembly towards the central chassis structural plate

and align the two central slots with the previously loosened chassis-tube

bolts [Figure 3]. The table bracket should be seated between the spacer

tubes and the gray central chassis structural plate.

4. Using a 1/8 inch hex wrench, attach the mounting bracket with the 3

supplied bracket mount screws and nuts [Figure 3]. After tightening these

screws, turn the two center-most chassis bolts until tight, fully securing the

mounting bracket to the central chassis structural plate.

5. Turn the unit upright and secure to a tabletop edge using the clamp of the

mounting bracket [Figure 4]. Rotate the bracket tensioning bolt [Figure 2]

until it is perpendicular to the underside of your mounting surface. Turn until

it contacts the underside of the surface. Do not over tighten. Turn till finger-

tight and then using a wrench, turn one-half turn more. Then lock the bracket

by tightening the pivot set screw.

1.3

STEERING WHEEL ASSEMBLY

1. With the wheel unit upright and secured to the tabletop the steering wheel

and shift paddles can be mounted. Prior to assembly inspect the shift paddle

set [Figure 5]. Note the importance of the two wire management slots at the

back side of the paddles. These slots accommodate the button wiring when

the paddle/wheel assembly is tightened down to the steering unit hub. It is

critical that the wires pass through these slots and avoid getting pinched

during assembly.

Remove the five wheel attachment screws from the paddle set. Discard

the small nuts that held them at the back of the assembly. From front to

back, the screws will pass through the steering wheel, optional wheel

spacer (if supplied), the shift paddle assembly, and into the threaded

holes in the hub