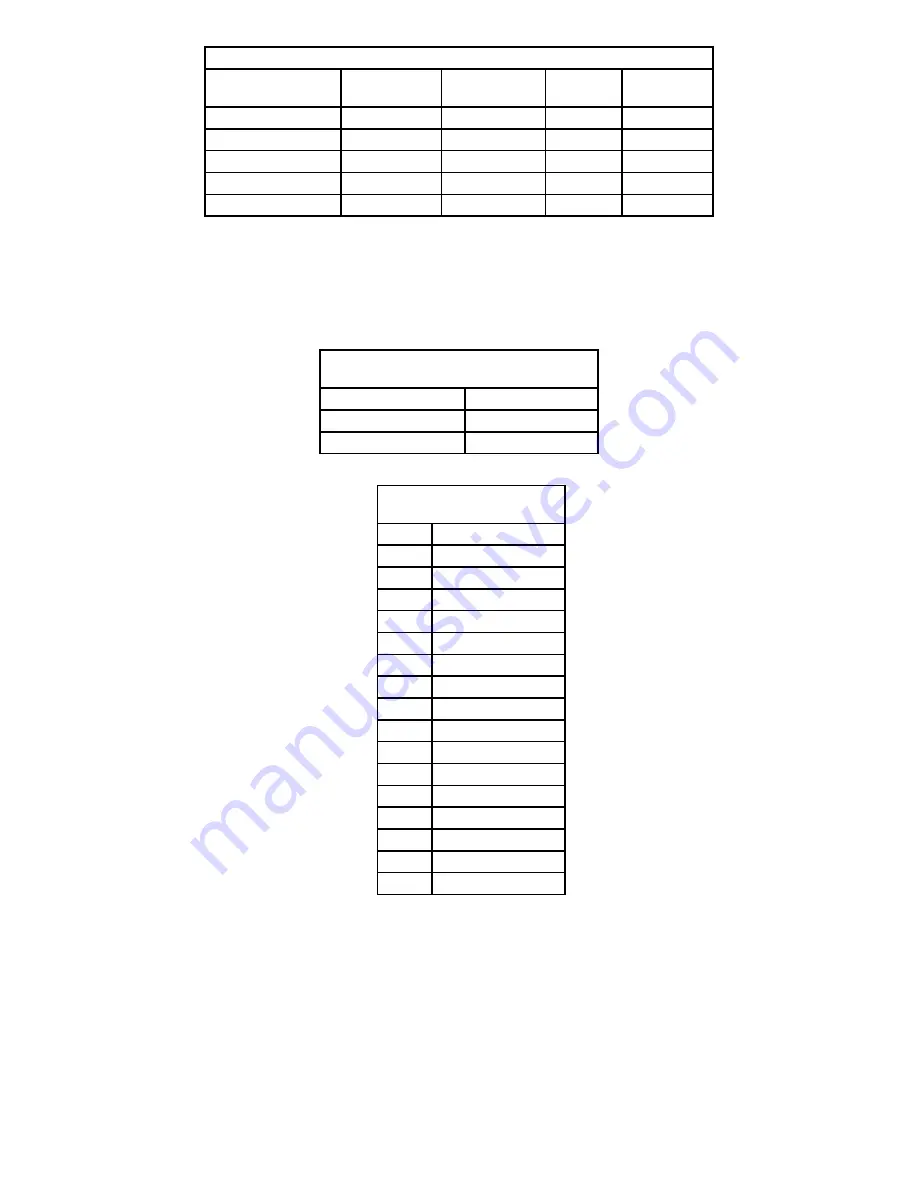

Level Mode Default Patterns by Group - Synchronized

Light Head Group

Flash Rate

L1

L2

L3

Front

Quad 75 FPM Quad 75 FPM

Cycle

Rear

Quad 75 FPM Quad 75 FPM

Cycle

L1 + L2

L1 + L3

L2 + L3

L1 + L2 + L3

Front

Quad 75 FPM Cycle

Cycle

Cycle

Rear

Quad 75 FPM Cycle

Cycle

Cycle

TABLE 9

To change a light head group flash pattern rate selection:

1. Power-up the Lightbar and apply +power to the appropriate level mode wires (see Table 3) and the BLK/RED Pattern select wire in the

16 conductor cable.

2. Momentarily touch the appropriate light head group wire, shown in Table 10, to +power to cycle through the flash pattern rates shown in

shown in Table 11.

Light Head Group Flash Rate Wires -

Synchronized

Function Wire Color Light Head Group

BLK

Front

BLU/WHT

Rear

TABLE 10

Light Head Group Flash

Rates - Synchronized

Order Flash Pattern

1

Double 75 FPM

2

Triple 75 FPM

3

Quad 75 FPM

4

Quint 75 FPM

5

Triple Pop 75 FPM

6

Quad Pop 75 FPM

7

Single 150 FPM

8

Double 150 FPM

9

Triple 150 FPM

10

Quad 150 FPM

11

Quint 150 FPM

12

Triple Pop 150 FPM

13

Quad Pop 150 FPM

14

Single 375 FPM

15

NFPA Qud 77 FPM

16

Cycle Flash

TABLE 11

To restore the Factory Default Emergency Warning Flash Rate to module group in a level mode, hold the appropriate rate selection wire

and the BLK/RED wire to +power for more than four seconds. The four corner light heads will flash once, and then stay on to indicate that

the Factory Default Emergency Warning Flash Rate has been restored.