Wiring Instructions:

Important:

Disable power before wiring the beacon.

Notes:

1. Larger wires and tight connections will provide longer service life for components. For high current wires it is highly

recommended that terminal blocks or soldered connections be used with shrink tubing to protect the connections. Do

not use insulation displacement connectors (e.g., 3M Scotchlock type connectors).

2. Route wiring using grommets and sealant when passing through compartment walls. Minimize the number of splices

to reduce voltage drop. High ambient temperatures (e.g., under-hood) will significantly reduce the current carrying

capacity of wires, fuses, and circuit breakers. All wiring should conform to the minimum wire size and other recom-

mendations of the manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable ties,

and similar installation hardware should be used to anchor and protect all wiring.

3. Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized to

protect the wiring and devices.

4. Particular attention should be paid to the location and method of making electrical connections and splices to protect

these points from corrosion and loss of conductivity.

5. Ground termination should only be made to substantial chassis components, preferably directly to the vehicle battery.

6. Circuit breakers are very sensitive to high temperatures and will “false trip” when mounted in hot environments or

operated close to their capacity.

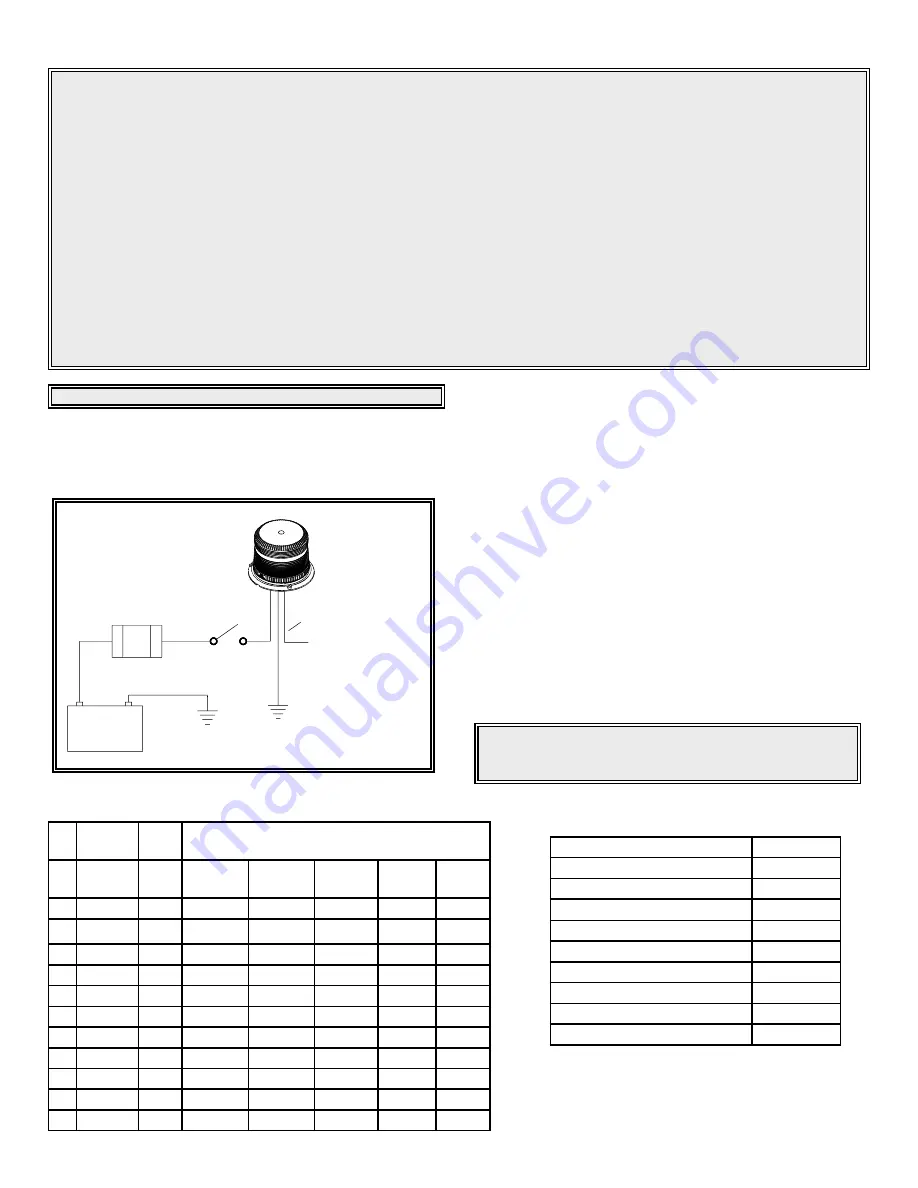

(+)

(-)

RED

BLACK

GROUND

GROUND

SWITCH

(USER SUPPLIED)

FUSE (5 AMP)

(USER SUPPLIED)

YELLOW

FLASH PATTERN SELECT

(ISOLATE WHEN NOT IN USE)

Figure 2

Maintenance:

This LED beacon has been designed for trouble free operation.

There are no periodic maintenance needs for this model.

Troubleshooting:

1. Most beacon failures, including intermittent or erratic operation

as well as failure of operation can be traced to wiring or battery

problems. Check all wiring, connections, fuse, switch, and bat-

tery voltage to insure that the correct voltage is reaching the

beacon.

2. If this has not remedied the problem, return product to your

local

dealer for warranty replacement

.

Note:

Operating the vehicle without the lens installed on

this product will result in damage that will not be covered

under warranty.

The wiring configuration is shown in Figure 2 below. All wiring

should be a minimum of 18AWG. A switch may be used to control

the on/off function. The black (negative) wire is connected to the

battery ground.

SAE J845 (2013) APPROVAL LEVELS

#

Pattern

FPM

7975A

7980A

7975B

7980B

7975C

7980C

7975G

7980G

7975R

7980R

1

Single

60

-

-

-

-

-

2

Single

120

CLASS 1

-

CLASS 1

-

-

3

Double

80

CLASS 1

CLASS 2 CLASS 1

-

-

4

Double

122

CLASS 1

-

CLASS 1

-

-

5

Triple

75

CLASS 1

-

CLASS 1

-

-

6

Quad

75

CLASS 1

CLASS 2 CLASS 1

-

-

7

Quad

122

CLASS 1

-

CLASS 1

-

-

8

Quint

75

CLASS 1

CLASS 2 CLASS 1

-

-

9

Burst 8

75

CLASS 1

CLASS 2 CLASS 1

-

-

10 Random

N/A

-

-

-

-

-

11 Steady

N/A

-

-

-

-

-

Flash Pattern Selection:

Flash patterns can be selected by touching the yellow wire to the

red power wire for less than a second. Contacting the yellow and

red wires for longer than a second toggles to the preceding flash

pattern.

Replacement Parts & Accessories:

Description

Part Number

Lens, 4”

R6050LX*

Lens, 6”

R6070LX*

Self Leveling Bracket

A6600SLB

Branch Guard

A6050BG

Branch Guard

A6070BG

Dust Cover

A6050DC

Dust Cover

A6070DC

Vibration Dampening Kit

A6600VDK

Black Top Decal

A6501BT

*where (X) indicates color:

A = Amber

B = Blue

C = Clear

G = Green

R = Red