3

Ope ra tor’s In struc tions

Im por tant

Prin ci pal da ta

Ty pe

Max. work ing

Paint cup

pres su re

volume

Ec co

bar

l

30 7

-

301 7

1

302 7

0.5

303 7

0.25

Use Ec co gen u ine parts and ac ces so ries on ly for best

func tion and safe ty.

Be fore start ing, read through

all in struc tions

care ful ly.

Do not use halogenated hydrocarbons in coating ap pli ca tion

equipment where aluminium or gal va ni zed parts come

in contact with the solvent or coating ma te ri al.

Ha log en at ed hydrocarbons e.g. 1,1,1-thri chlo ro et ha ne and

methylene chloride react, violently with such parts, causing

corrosion and dan ger for ex plo sion.

WAR NING

The high vel o ci ty flow of air and li qu ids through ho ses and

nozz les may de ve lop sta tic elec tri ci ty. Be su re that the

equ ip ment, object being spray ed, spray booth, paint and was te

con tai ner are pro per ly groun ded to pre vent sta tic di scharge

or sparks.

WAR NING

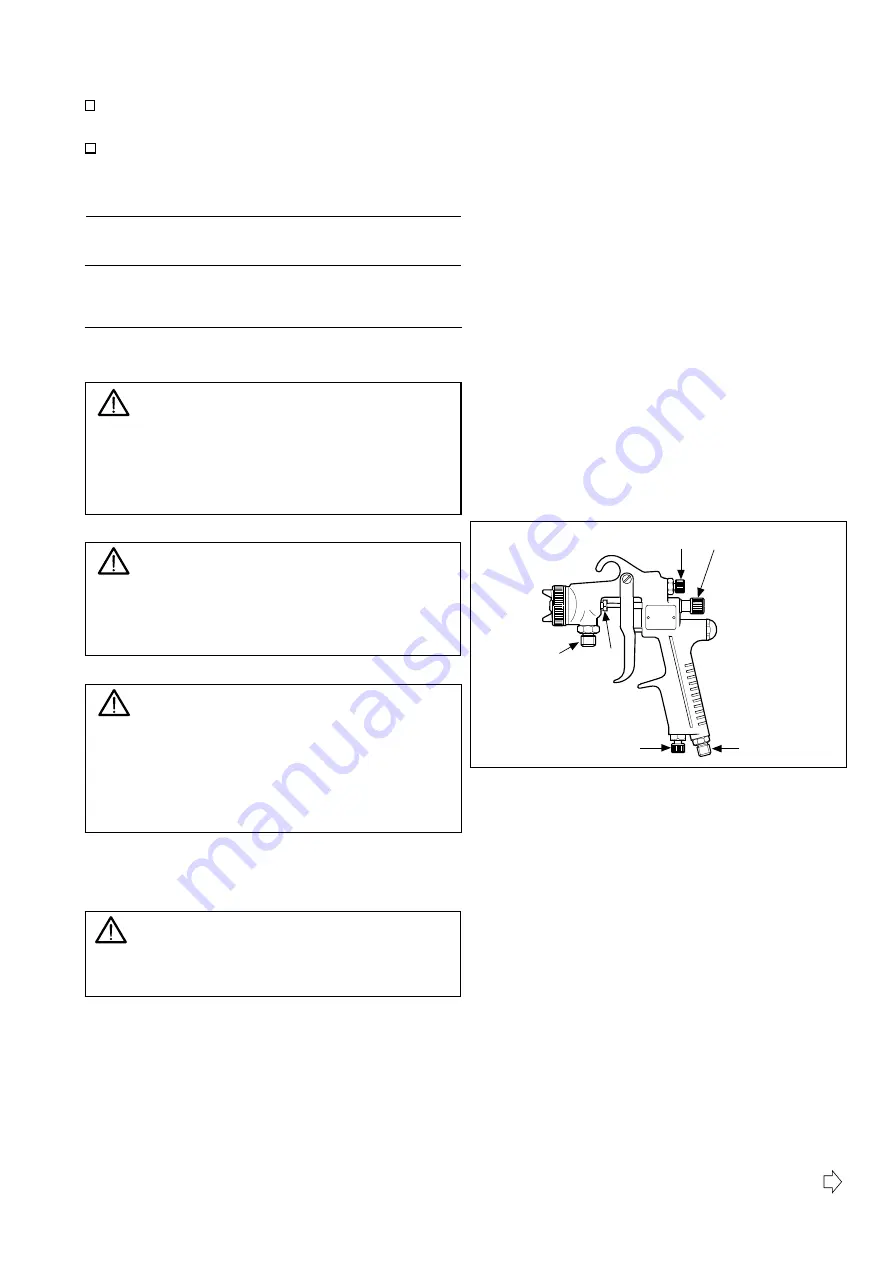

Op er a tion

•

In stall and op er ate the spray gun ac cord ing to Fig. 1.

•

Blow the paint and air hoses clean before connection.

•

Check that all connections are tight (pay particular attention to the

connection between paint cup and spray gun).

•

Keep the spray gun clean and lu bri cate mov ing parts at regular

intervals.

•

Lu bri cants for sur face-treatment equip ment must

not

con tain

sil i con.

Con nec tions and con trols

(see Fig. 1)

A

At o miz ing air hose con nec tion G 1/4.

Hose: In side dia. 6.3 mm (1/4”).

B

Paint hose con nec tion G 3/8.

Hose: In side dia. 6.3 mm (1/4”) or 9.5 mm (3/8”).

F

Paint needle packing adjusting screws.

D

Fan width ad just ing. If the knob is screwed all the way in a rounfan will

be ob tained other po si tions give broad fans.

E

Paint flow ad just ing. Clock wise turn ing re sult in a small er paint flow

and coun ter-clock wise turn ing in creas es the flow. The fluid flow is

regulated in the first instance by the choice of paint noz zle and paint

pres sure.

Paint spray ing

How to operate

Recommended paint viscosity differs according to paint properties and

painting conditions. 15 to 23 sec./Ford cup 4 is recommendable.

The gun is operate at low air pressure, high transfer efficiency will not be

obtained if the spray distance is to far.

Set the spray distance from the gun to the work piece as near as possible

within the range of 150-300 mm.

Air caps

The air caps are tested and certified according to the SEAVA metod.

This gives a ”finger print” of the spray pattern on each air cap.

For further information please contact your supplier.

The retaining ring for the air cap shall only be tightened with hand force.

No tools are required. Especially important when a capcleaner is used.

Air caps can be sent back for checking and comparity the performance.

For further interesting please contact your supplier.

•

In the event of leakage around the paint needle, tightening the packing

screws (see F Fig. 1). After tightening, check that fluid needle is pushed

forward by the spring force.

• For short standstill periods, for instance over a night, it will

suf fice to clean the air and paint nozzles on the outside. If a

two-com po nent paint is used, however, the gun

must be flushed

through

im me di ate ly

with solvent. This must also be done if the

gun is to re main unused for a longer period of time.

•

When cleaning the air cap and the paint nozzle, use a soft brush

or rag dipped in solvent. Do not place the entire gun in solvent,

as the oil on the lubricated parts would be dissolved. Blow the air

cap dry with compressed air from both sides.

•

Nev er use iron or steel wire to clean air holes and ducts in the

noz zles.

As the equipment works under pres su re the ut most care must

be observed during the work. Bearing this in mind, never aim

the spray gun at a person or towards any part of the bo dy In

the event of personal injury caused by the spray ing pressure,

immediate medical attention is essential. Before carrying out

any adjustment or repair, the equipment must be swit ched off

and the paint pres su re re li e ved.

WAR NING

In ha la tion of paint, paint dust and sol vent is not he al thy. Ma ke

su re an ap pro ved spray booth is used. The ope ra tor must use

per so nal pro tec tion-breath ing mask or fresh air hood.

CAU TION

ECCO 30

65130 F205

Fig.1