Troubleshooting

Introduction

Always commence troubleshooting by checking the general condition

of the spray gun. This can most easily be determined by test spraying,

which provides an opportunity for checking the spray pattern and capacity,

air leakage and gasket leakage.

The following external factors can cause malfunctioning and should be

thoroughly checked:

1. The quality of the air, i.e. content of moisture, dirt particles and oil.

2. The quality of the paint, i.e. its viscosity, purity. etc.

3 The air and paint pressure in relation to viscosity of the paint and

nozzle combination used.

4. The size of the air/paint hoses.

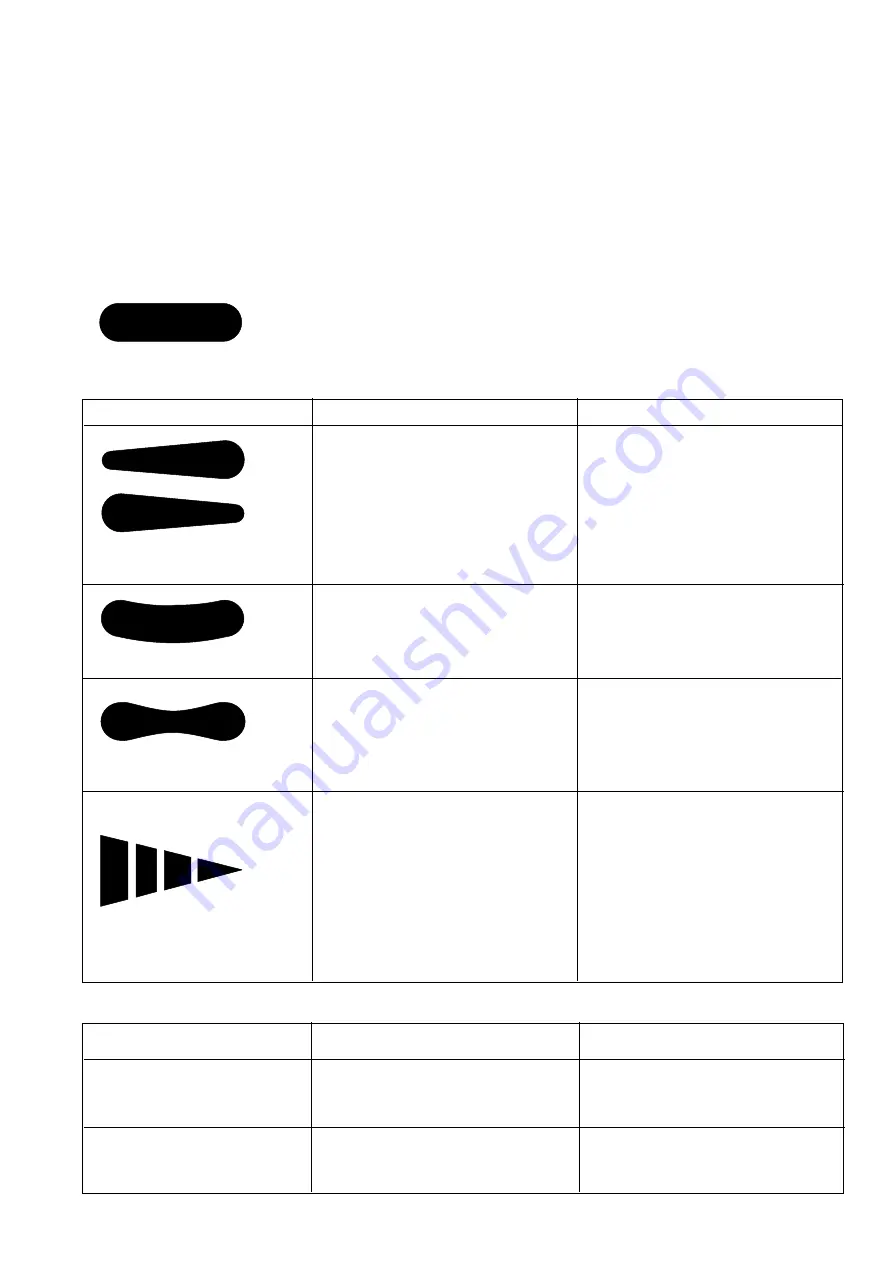

Troubleshoouting chart

Correct Spray Pattern

Types of problems

Collection of information which makes it possible to identify the error

symptoms applicable to the spray gun in the event of malfunctioning

is a matter of vital importance. Identification of symptoms makes it

possible to decide whether the spray gun itself is the direct cause of the

malfunctioning or if this may have been caused by an external factor.

Paint leaking

Worn needle packings and/or needle.

Replace damaged parts with new ones.

Paint leaking through the paint nozzle

when the gun is closed.

Pollution between the needle and the nozzle

or needle and nozzle worn or damaged.

Unscrew air cap (1) and nozzle (2). Clean carefully

and check for any sign of damages or wear.

Paint leaking - Air leaking

Cause

Remedy

a) Dried paint on holes for atomizing air.

Clean the air holes, use appropriate cleaning

agent and a soft brush.

b) Damage to holes for atomizing air.

Replace the air cap with a new one.

c) Air cap not sufficiently tightened.

Tighten the air cap properly by hand.

Asymmetrical to the left or

to the right

a) Dried paint on holes for atomizing air.

b) Damage to holes for atomizing air.

c) Air cap not sufficiently tightened.

Distorted in the middle

a) Damage to the tip of the paint nozzle.

b) The pressure of the atomizing air in relation

to the viscosity of the paint.

a) Fit a new paint nozzle.

b) Adjust the air pressure of the atomizing air.

Spray Pattern

Cause

Remedy

Narrowing off in the middle

a) Wrong nozzle combination.

b) Fan air pressurer too high.

c) Paint viscosity unsuitable.

d) Incorrect spray angle.

a) Select a new nozzle combination suitable

for the viscosity of paint.

b) Reduce the pressure of the fan air.

c) Adjust the viscosity of the paint.

d) Adjust the angle with the fan width control.

Irregular spray (spitting)

a) Paint needle gasket leaky.

b) Paint nozzle not tightened.

c) Dirt on sealing surfaces of paint nozzle and

distributor ring.

d) Paint hose connection not tightened.

e) Paint hose defective.

a) Adjust the packing screws. If this does not

suffice, change the paint needle gaskets.

b) Tighten the paint nozzle.

c) Clean the sealing surfaces of the paint nozzle

and distributor ring with solvent and blow

clean.

d) Tighten the paint hose connection.

e) Change the paint hose.

5