21

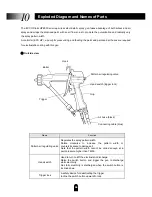

[Electrostatic spray gun]

※

For part names, see pages 30 and 31.

Symptom

Cause

Countermeasure

Red lamp on

controller lights but

electrostatic spray

effect is not

sufficient.

Electric resistance of paint is not

appropriate.

Adjust the electric resistance of paint to

between 10 and 100M

Ω-cm at AC500V.

Gun tip is contaminated and

high-voltage current is leaked,

resulting in a gun tip voltage drop.

Wipe off paint with a cloth soaked with

paint thinner.

Many splashes of

paint

Paint is sprayed toward a too long

distance.

Spray at an appropriate distance (200mm

to 300mm).

Paint pressure or air pressure is too

high.

Reduce the pressure.

The product being coated is not

grounded.

Class D or better grounding is required

(see the Research Committee

’s Report

issued by the Japan Industrial Safety &

Health Association).

Sparks sometimes

come out of nozzle

during spraying

operation.

Damaged cascade

※

Replace cascade with a new one.

Warning buzzer on

the control unit

sounds.

A high-voltage current leaks through

moisture contained in the

compressed air.

Supply dry compressed air using an air

drier or the like.

Electric resistance of paint is too low.

Adjust the electric resistance of paint to

between 10 and 100M

Ω-cm at AC500V.

Contaminants on gun

Clean the gun.

Nozzle is heavily

clogged.

Material filter mesh size is too large.

Select a filter mesh suitable for the nozzle

to be used.

Poorly cleaned gun

Especially when using two-component

paint, thoroughly clean with exclusive

paint thinner.

Paint leaks through

the root of gun

extension.

Worn U-packing at needle shaft

Remove trigger and seat set and replace

needle set with a new one.

Paint leaks from air

outlet in nozzle or

its periphery.

Worn or damaged seat at gun tip

Replace seat set with a new one.

Nozzle is not a high pressure type.

Use type ENH nozzle, which has a black

resin part and a protrusion on seat.

Paint comes out of

the tip of nozzle

when gun is not

triggered.

Worn needle

Remove trigger and replace needle set

with a new one.

Seat is clogged with foreign matter.

Remove seat set and clean needle seat.

8

Troubleshooting