13

Lubrication

WARNING: Before lubricating, repairing,

or inspecting the machine, disengage all of the

controls and stop the engine. Wait until all

moving parts have come to a complete stop.

Wheels

At least once a season, remove both wheels. Clean

and coat the axles with a multipurpose automotive

grease before reinstalling the wheels.

Chute Directional Control

Once a season, the joystick should be lubricated

with petroleum jelly, linseed oil, mineral oil, paraffin

wax or 3-in-1 oil.

Gear Shaft

The gear (hex) shaft should be lubricated at least

once a season or after every 25 hours of operation.

1. Remove the lower frame cover by removing the

two screws which secure it.

2. Apply a light coating

of all-weather

multipurpose grease

to the hex shaft.

IMPORTANT: Avoid

spilling oil on the

rubber friction wheel

and aluminum drive

plate.

Gear Case

The auger gear case has been filled with grease and

sealed at the factory. If it is disassembled for any

reason, lubricate it with two ounces of new grease.

NOTE

: Do not over fill the gear case. Damage to

the seals could result. Be sure the vent plug is free

of grease in order to relieve pressure.

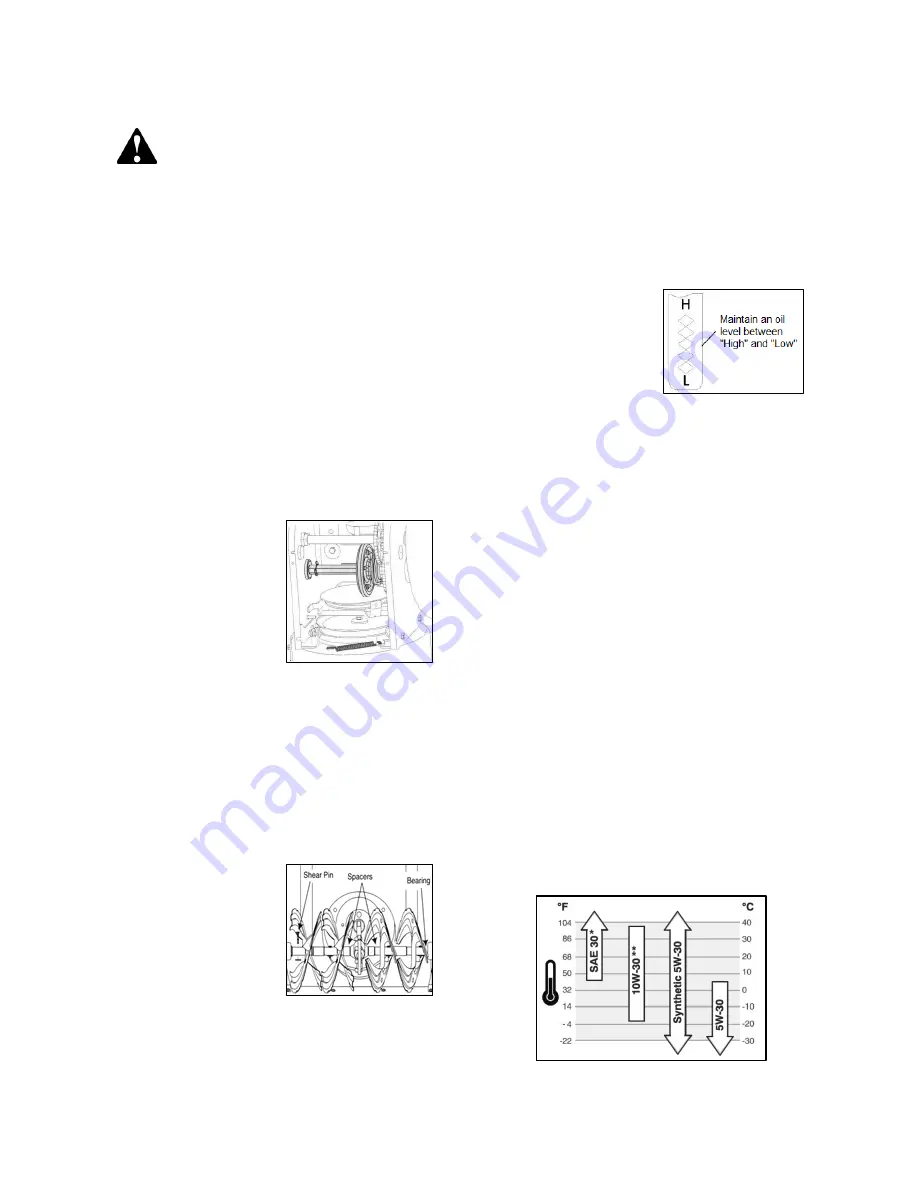

Auger Shaft

At least once a season,

remove the shear pins on

the auger shaft. Spray

lubricant inside the shaft,

around the spacers, and

on the flange bearings

found at either end of the

shaft.

Maintenance

Checking the Engine Oil

1. Be sure that the engine is upright and level.

2. Unscrew the oil fill cap from the oil filler tube

and wipe dipstick clean.

3. Screw the oil cap back into the oil filler tube

and tighten it securely.

4. Unscrew and remove the oil fill cap from the

oil filler tube.

5. Note the oil level.

If the oil reading

on the dipstick is

below the

“LOW”

mark, slowly add

oil to reach the

“HIGH” level.

6. Screw the oil fill cap back into the oil filler

tube and tighten it securely.

7. Wipe away any spilled oil.

Changing Engine Oil

To avoid engine damage, it is important to:

•

Check the oil level before each use and after

every five hours of operation.

•

Change the oil after the first two hours of use, and

after every 25 hours of operation thereafter.

When checking and changing the oil, the engine

should still be warm but not hot from recent use.

To change the oil, use the following procedures:

1. Locate the oil drain plug.

2. Make certain that the gas cap is on and

tightened securely.

3. Clean the area around the oil drain plug.

4. Place an approved recyclable oil container

under the oil drain plug.

5. Remove the oil drain plug and drain the oil.

Note

: Dispose of any used oil at a proper

collection center.

6. Re-install the oil drain plug and tighten it

securely.

7. Refill the engine with recommended oil.

The en

gine’s oil capacity is 26 oz.

8. Wipe away any spilled oil.