10

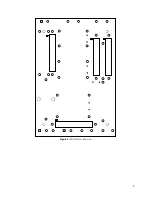

Installation of PCBs Into Crossover Assembly

After allowing the boards to cure overnight, you’re now ready to install the new PCBs into the

factory crossover assembly.

1.

Align the PCB mounting holes with the four snap

-

lock board mounts on the crossover

board, and gently snap each corner into place, one at a time. The board orientation should

match that shown in Figure 3.

2.

Insert the stripped ends of the black and red wires from the binding posts into the plated

through holes E1 (IN+, red wire) and E2 (IN

-

, black wire). Solder both wires to the PCB.

3.

Insert the tinned ends of the two wires from the inductor mounted on the crossover

assembly to pads E3 and E4 (also denoted by “L2” on the PCB silkscreen). Solder both

wires to the PCB.

4.

Obtain one of the 9V battery connectors with flying leads. Cut the leads down to about

1

-

1.5 inches in length, strip the ends, and insert the red wire into the PCB pad marked 9V

battery “+” (upper right corner of the PCB). Insert the black wire into the PCB pad to the

left of that. Solder both wires to the PCB.

5.

Obtain one of the 9V battery clips and the double

-

sided tape and cut a piece of tape to fit

to the bottom surface of the mounting clip. Affix one side of the tape to the bottom of

the clip and press down to adhere.

6.

Place a 9V battery in the clip, center it, and then remove the protective layer on the

exposed side of double

-

sided tape. Place the battery and clip down on the right side of

the crossover assembly mounting plate, choosing the location such that there is enough

room to remove/install the battery, and enough room to attach the battery connector and

wires. Use Figure 3 as a guide on placement. Remove the battery from the clip while

holding the clip down to the surface (you don’t want to lift the tape up inadvertently).

Press down firmly on the bottom of the clip to increase the adhesion of the tape. If the

tape accidentally lifts from the crossover, start over with a fresh piece of tape, as it will

take small debris from the fiberboard with it, and won’t adhere as well on the next

attempt. This may sound complicated from the detailed description, but it’s quite simple.

Note that the battery can slide back and forth in the clip, so the exact placement of the

clip is not critical.

7.

If remnants of the old strain relief clamp (refer to Step 6 of the “Removing Crossover

from Speaker” section) are still in place, remove them carefully with a putty knife or other

tool (the old, brittle adhesive should chip away easily). If this is proving difficult, leave it

there and move to the next step.

8.

In the location of the old strain relief clamp (or adjacent to it, if you couldn’t get it fully

removed), place an adhesive

-

backed zip tie mount and press down to adhere.

9.

Repeat steps 1 through 8 for the other PCB and crossover assembly.