28

STOPPING

ENGINE

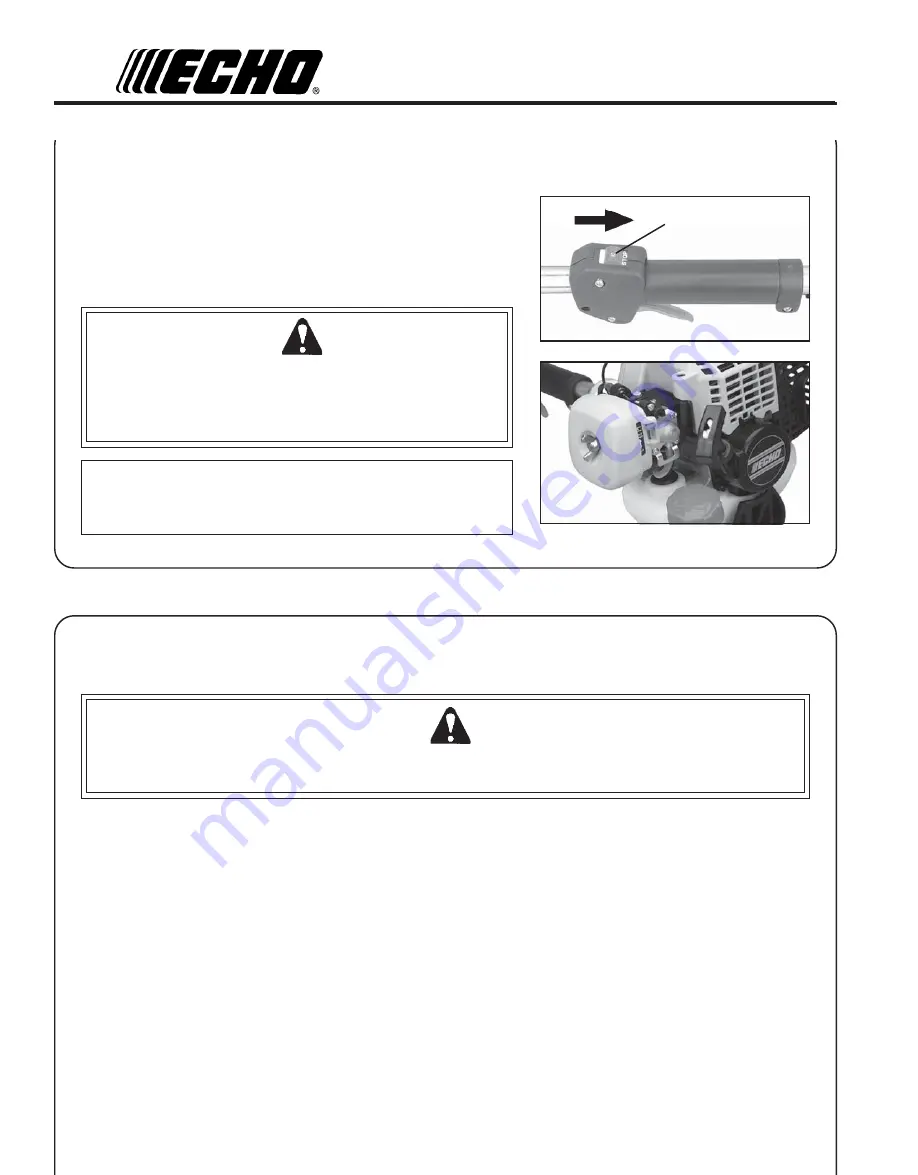

1.

Release Throttle. Allow engine to idle for a minute.

2.

Stop Switch - Stop. Move stop switch button (A) backward to

STOP position.

WARNING

DANGER

If engine does not stop when stop switch is moved to STOP

position, close choke - COLD START position - to stall engine.

Have your ECHO dealer repair stop switch before using trimmer

again.

NOTE

Refer to Grass Trimmer/Brush Cutter Safety Manual for proper and

safe techniques.

A

M

AINTENANCE

WARNING

DANGER

Catalytic mufflers operate at extremely high temperatures. Muffler area must be kept clean. Do not perform mainte-

nance on engine or muffler until engine and muffler are completely cool, otherwise serious personal injury may occur.

Your ECHO trimmer is designed to provide many hours of trouble free service. Regular scheduled maintenance will help

your trimmer achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your

unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or have the

ECHO Dealer do it, each maintenance task has been graded. If the task is not listed, see your ECHO Dealer for repairs.

SKILL

LEVELS

Level 1 =

Easy to do. Most required tools come with unit.

Level 2 =

Moderate difficulty. Some specialized tools may be required.

Level 3 =

Experience required. Specialized tools are required. ECHO recommends that

the unit be returned to your ECHO dealer for servicing.

ECHO offers REPOWER

TM

Maintenance Kits and Parts to make your maintenance job easier. Below each task heading

are listed the various part numbers required for that task. See your ECHO dealer for these parts.