In-tank Filter

8E

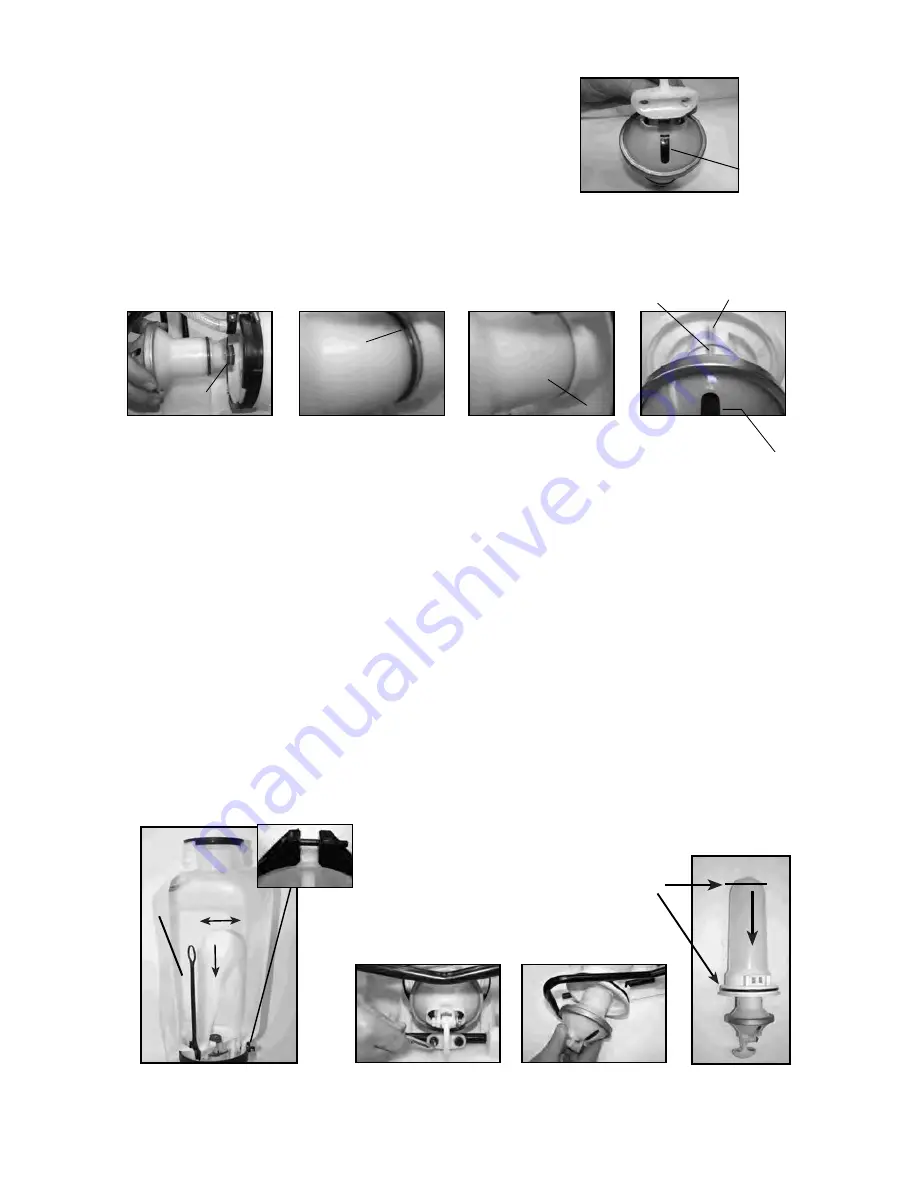

8) Apply Petroleum jelly to 2 diaphragm pump o-rings (Fig. 6a).

Thread diaphragm pump assembly into pressure chamber base,

making sure the o-ring seats inside the pressure chamber base

(Fig. 6b-6c). Align the diaphragm pump alignment mark with the

pressure cylinder base alignment mark (fig.6d).

The slot in the diaphragm cover will also be in alignment.

9) Re-assemble pump shaft (see step 3).

10) Re-attach pivot lever to pump shaft (see step 2).

Only remove the pressure cylinder if the cartridge filter is clogged or the sprayer is

leaking from where the pressure cylinder o-ring and tank meet.

DISASSEMBLING AND REPAIRING THE PUMP ASSEMBLY

7) Attach pivot lever and connection hardware to new diaphragm pump

assembly. Make sure orientation is correct with slot in diaphragm cover

( Fig. 5).

Figure 5

Figure 6d

Pressure Cylinder Base

Alignment Mark

Diaphragm Pump

Alignment Mark

Diaphragm

Cover Slot

Figure 6c

Pressure

Cylinder Base

Figure 6b

O-ring

Figure 6a

O-rings

1. Release the pressure from the sprayer and remove all liquid from both the pressure cylinder and tank.

2. Remove Hose

3. Remove the In-tank Filter from the pressure cylinder (located inside tank fig 1).

4. Remove the large clamp holding the pressure cylinder and tank together (fig 1).

5. Rock the pressure cylinder back and forth and push down forcefully to free it from the tank (fig 1).

6. Once freed the entire assembly can be removed by angling and maneuvering it through the base frame

(fig 3a & 3b).

Figure 2

Figure 3a

Figure 3b

Pressure

Cylinder o-ring

Diaphragm

Cover Slot

Clamp

Figure 1

3F

INFORMATION D'UTILISATION ET COMPOSANTS DU PULVÉRISATEUR, suite

INSTALLER LA POIGNÉE DE POMPE

La poignée de pompe s'installe à l'une ou l'autre extrémité de l'arbre

de la pompe (A). Pour installer la poignée de pompe, placez la

poignée (C) sur l'arbre (A) en alignant le trou de la poignée de pompe

et le trou de l'arbre. Poussez le côté droit de la goupille fendue (B) à

travers le trou aligné tel qu'indiqué dans les figures 1 à 3. Il y a dans

trous dans la poignée de la pompe pour permettre un montage de

gaucher (fig. 4) ou droitier (fig. 5).

INSTALLER LA

BANDOULIÈRE

Le dessus des

bandoulières est fixé à

la cuve. Fixez

l'extrémité inférieure

des bandoulières en

attachant les crochets

de sangle à l'armature

de métal entre l'endroit

où celle-ci sort de la

cuve et où elle se

recourbe.

PINCE DU TUBE

Le tube s'installe à

la poignée de la

pompe en utilisant

la pince du tube.

A

C

B

Relevez

Tournez

de 180º

Placez

dans

la

fente

Pump Handle

Positioned For Use

(right hand shown)

Figure 5

Droitier

Figure 4

Gaucher

POIGNÉE DE POMPE ESCAMOTABLE

Figure 1

Goupille fendue

Figure 2

Alignez les trous

Figure 3

Glissez la goupille à travers les trous.