5 INCH PTO CHIPPER

6

ASSEMBLY

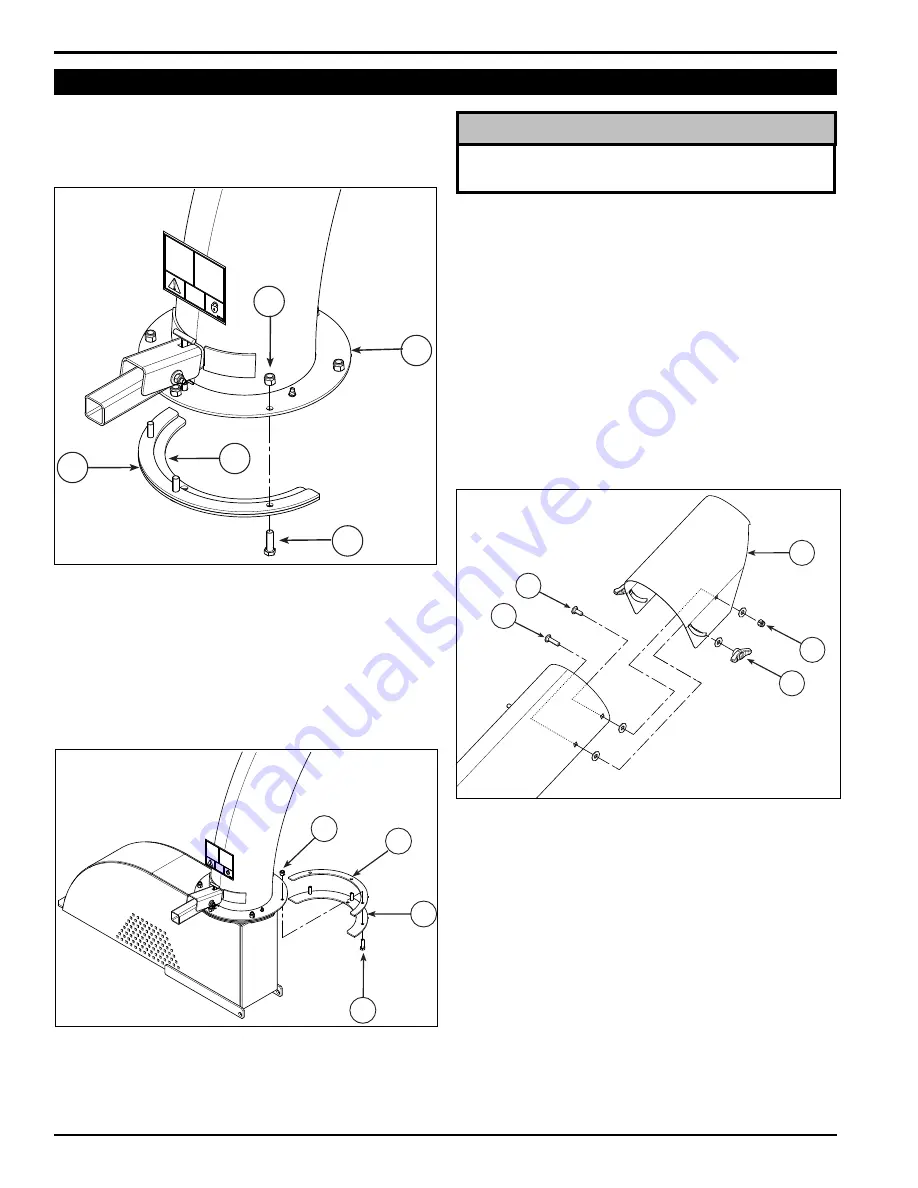

2.2 aTTaCH DIsCHarGe TuBe

Keep nuts as tight as possible while allowing the

discharge tube to freely turn.

noTe

1.

Attach one clamping ring(1) and one spacer ring(2) to

discharge tube base(3) using three 3/8 x 1 1/4" bolts(4)

and nylock nuts(5). Tighten leaving 1/16" gap to assist

in mounting to flange. See Figure 2.2.

2. Slide the tube onto the mounting flange on the chipper

frame. The discharge clamp(1) should slide underneath

the lip of the flange. Tighten the bolts and nuts to

secure it.

3.

Install the second half of the spacer(2) and clamp

ring(1) on the discharge tube with 3/8 x 1-1/4" bolts(4)

and nylock nuts(5).

1

2

3

4

5

6

7

9

8

10

Figure 2.4, Attach discharge deflector

Figure 2.2, Attach clamp ring and spacer

Figure 2.3, Attach discharge tube

4.

lubricate the chute by applying grease to the grease

zerk at the base of the chute. Rotate the chute and

apply grease until the chute rotates freely.

5. Rotate the tube 360 degrees and lock it in place with

the lock pin to make sure it is mounted correctly.

6.

Attach the discharge deflector(6) to the discharge tube.

Connect the deflector with two 5/16 X 1 1/4" bolts(7)

through the lower hole in the discharge tube. Run these

bolts through the inside of the tube, washer, deflector,

washer, and then knob(8).

7. Finish bolting the deflector to the tube with two 5/16 x

1" bolts(9) through the end hole in the discharge tube

and secure with 5/16 washers & nylock nuts(10).

1

2

4

5