17

8 INCH CHIPPER

ENGLISH

SERVICE & MAINTENANCE

WARNING

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

5.11 ROTOR BEARINGS

1. Rotate discharge to the right side of the machine.

Open access cover (see Section 5.3). Tilt the access

cover open to allow access to the rotor.

2.

Remove upper and lower belt guards (10-5/16 bolts).

5.11.1 FRONT BEARING REMOVAL

3. Remove the idler tensioning springs, and remove the

1/2" bolt holding the idler pulley in place.

4. Remove the drive belt.

5. Taking the bolts out of the pulley and reinserting them

into the empty holes, slowly tighten each bolt in a

rotating clockwise direction to remove the bushing

and sheave from the rotor shaft.

6. Loosen the set screw holding the spacer in place and

remove. If rear bearing does not need to be removed

go to step 11.

5.11.2 REAR BEARING REMOVAL

7. Remove the protective cap.

8. Remove the 3/8 bolt holding the retaining spacer and

remove the spacer.

9. Remove the four 1/2" bolts on each rotor bearing and

loosen the two set screws on each bearing. (Note: )

10. Remove and replace with new bearings.

11. Put the bolts back in the bearings and slide into place.

Tighten bolts to 75 ft-lbs. (102 Nm). Slide rear collar

back into place and insert 3/8 bolt.

12. Taking a rubber mallet, tap the rotor shaft until the

rear collar is tight against the rear bearing. Tighten

the bolt and lock the set screws on both bearings.

Torque to 180 inch-lbs (20 Nm). Reinstall front collar

and tighten the cap screw.

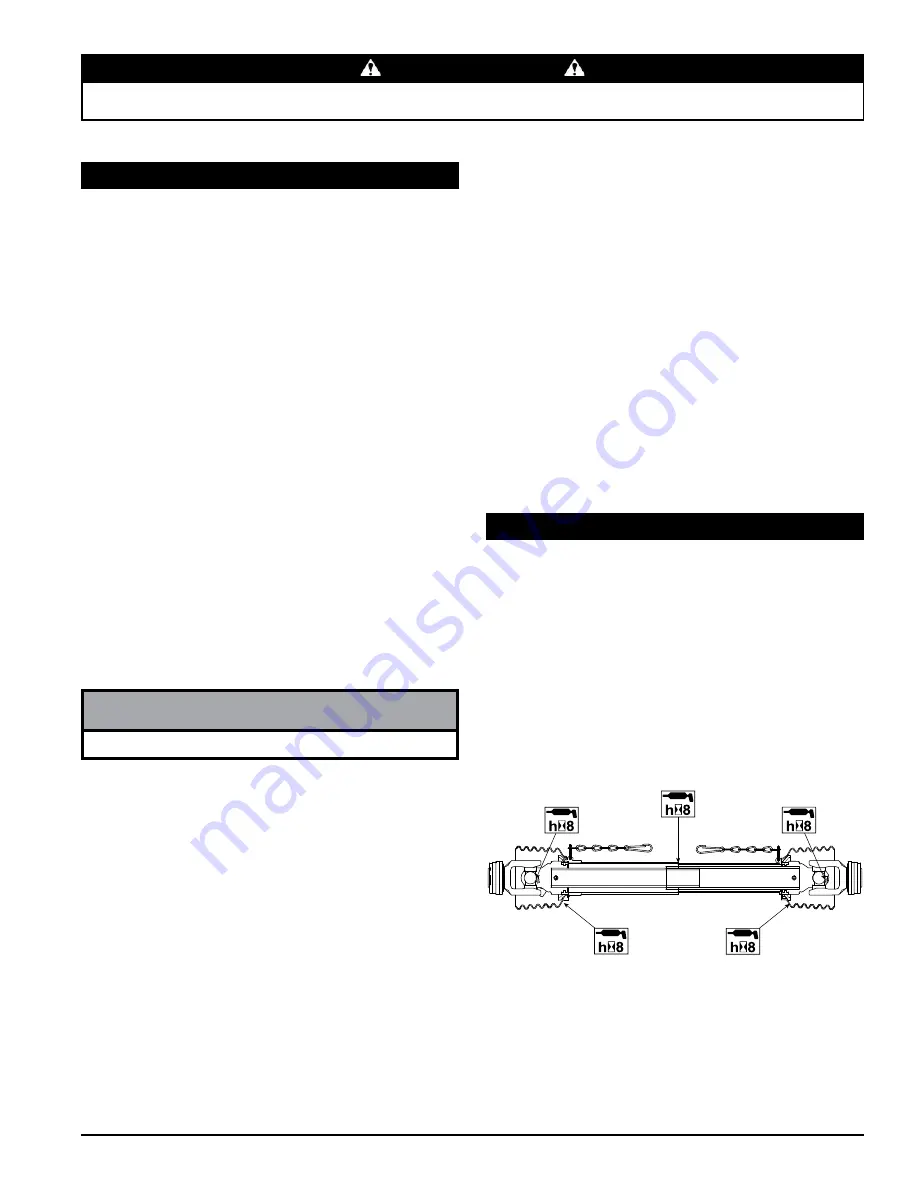

5.12 PTO DRIVELINE LUBRICATION

1.

Every 8 hours, lubricate PTO cross journals. Make

sure grease purges through all four bearings.

2. Every 8 hours, lubricate PTO inner tubes. Telescoping

members must have lubrication to operate

successfully. Telescoping members without fittings

should be pulled apart and grease should be added

manually with a brush.

3. Every 8 hours, lubricate the PTO shield retaining

bearing. Molded nipples on the guard near each

guard bearing are intended as grease fittings and

should be lubricated every 8 hours of operation.

13. Reinstall the rear rotor protective cap. Slide the

bushing on and tighten set screw, then slide the

sheave on. Insert bolts into the sheave and tighten in

a clockwise direction. Torque to 108 inch-lbs. (12 Nm).

14. Check the alignment of pulleys with a straight edge

and adjust if needed.

15. Replace the drive belt.

16. Replace the idler and tighten. Reinstall tensioning

springs.

17. Close access cover and secure as described in

Section 5.3.

18. Replace belt guard and resume operation.

19. Start tractor engine and engage PTO drive clutch

(see tractor owner’s manual). Increase engine speed

to rated PTO RPM position. Test unit; readjust pulleys

and belt tension if needed.

You may have to clean the shaft with emery cloth.

NOTE