SAW CHAIN LUBRICATION SYSTEM

CS-271T

44

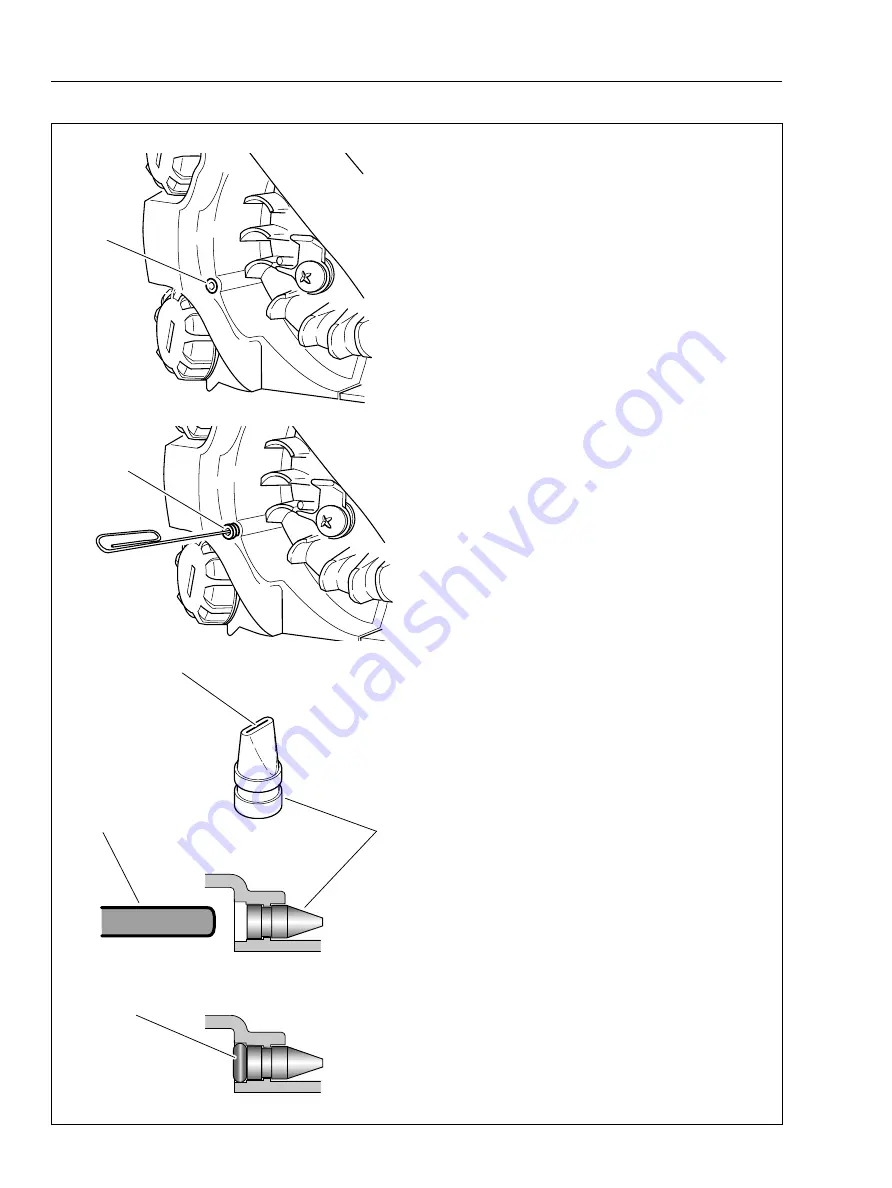

7-2 Inspecting oil tank vent

NOTE:

Oil tank vent prevents a vacuum from

forming in oil tank when chain oil in the tank is con-

sumed.

1. Remove starter assembly.

2. Remove O-ring (A).

3. Remove oil tank vent (B) using paper clip and

clean it.

4. Check that oil tank vent lips (b) are not hard or

deformed. Replace as required.

5. Install oil tank vent (B) using suitable tool (C) as

shown.

6. Reinstall O-ring (A) as shown. Reinstall starter

assembly.

B

C

A

b

B

A