25

CS-500P

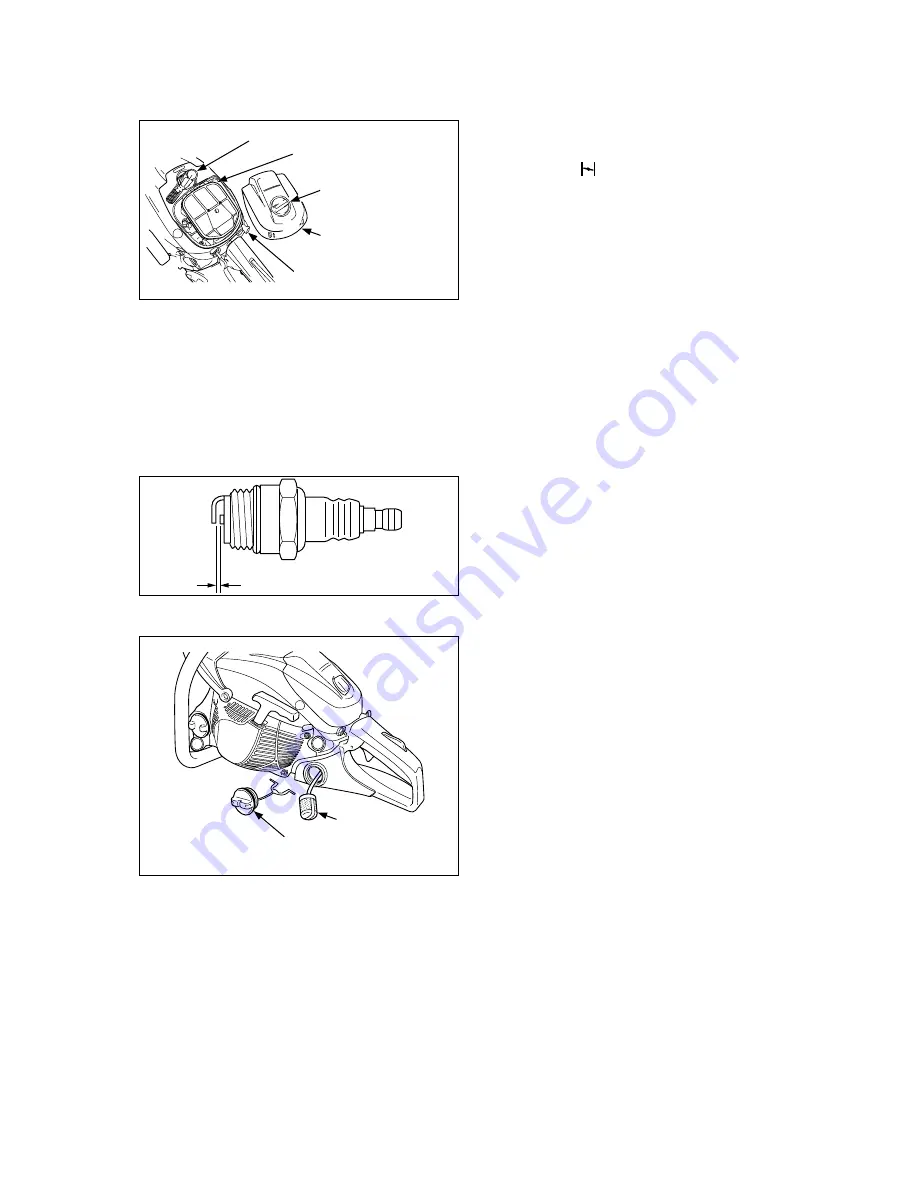

Fuel fi lter

Fuel tank cap

0.6 to 0.7 mm

Cleaner cover knob

Air fi lter

Air cleaner cover

AIR FILTER

• Check before every use.

• Close choke (

).

• Turn cleaner cover knob counterclockwise by

hand and remove air cleaner cover and air fi lter.

• Brush off dust lightly, or clean with compressed

air, or replace the air fi lter.

• Reinstall air fi lter and cover.

CHECK FUEL SYSTEM

• Check before every use.

• After refueling, make sure fuel does not leak

from around fuel pipe, fuel grommet or fuel tank

cap.

• In case of fuel leakage there is a danger of fi re.

Stop using the machine immediately and request

your dealer to inspect or replace.

SPARK PLUG

• Check

periodically.

• The standard spark gap is 0.6 to 0.7 mm.

• Correct the spark gap if it is wider or narrower

than the standard gap.

• Fastening torque: 15 to 17 N

·

m

(150 to 170 kgf

·

cm).

FUEL FILTER

• Check

periodically.

• Do not allow dust to enter fuel tank.

• A clogged fi lter will cause diffi culty in starting

engine or abnormalities in engine performance.

• Pull the fuel fi lter out through fuel inlet port with

a piece of steel wire or the like.

• When the fi lter is dirty, replace it.

• When the inside of the fuel tank is dirty, rinsing

the tank out with gasoline can clean it.

OIL FILTER

• Check

periodically.

• Do not allow dust to enter into oil tank.

• A clogged oil fi lter will affect the normal

lubricating system.

• Wash the oil tank and fi lter element with an

approved solvent.

• If damage or deterioration is noted on the oil

suction line, the saw must be removed from

service until it can be inspected by a ECHO-

trained service technician.

Spark plug

Choke control knob