17

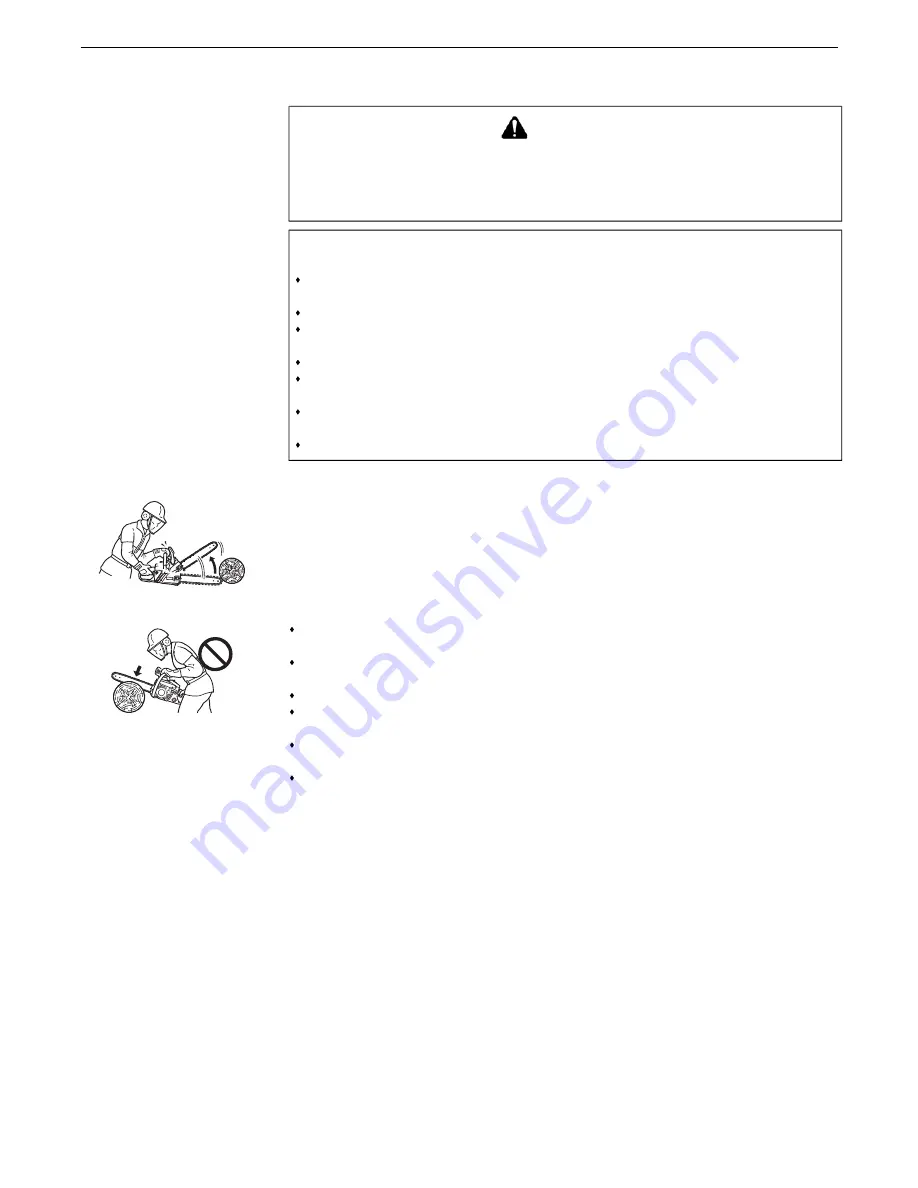

Correct use of chain brake

Chain brake

The chain brake's function is to stop chain rotation after a kickback.

It neither prevents nor reduces kickback.

Do not depend on the chain brake for protection against kickback.

Even with a chain brake, depend on your own good sense and proper cutting methods just as

though there were no chain brake.

Even with normal use and proper maintenance, the response time of the brake may lengthen.

The following may interfere with the brake's ability to protect the operator:

Saw wrongly held too close to operator's body.

Kickback time may be too fast even for a perfectly maintained brake to work in time.

The operator's hand may not be in position to contact the hand guard.

Brake will not be tripped.

Lack of proper maintenance lengthens the brake's stopping time, making it less effective.

Dirt, grease, oil, pitch, etc. getting into the working parts of the mechanism may lengthen

the stopping time.

Wear and fatigue of the activating brake spring, and wear of the brake / clutch drum and

pivot points may lengthen the brake's stopping time.

A damaged hand guard and lever may render the brake inoperative.

DANGER

Kickback motion is very hazardous.

If the tip of the bar touches wood or the like, the guide bar kicks back in an instant.

The chain brake reduces the possibility of injury due to kickback.

Always check that chain brake works properly before use.

NOTE

For practice, while cutting a small tree, push the front guard forward to engage the

brake.

At all times, confirm whether the brake works properly before each task.

If the chain brake is clogged with wood chips, function of the brake deteriorates a little.

Always keep the device clean.

Do not increase engine revolutions while the chain brake is engaged.

Chain brake is used in emergencies.

Do not use it unless absolutely necessary.

When using throttle latch at starting, keep the chain brake in position.

And after starting the engine, release the brake immediately.

Never test the brake in an area where petrol fumes are present.