22

CarbureTor

adJusTmenT

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel

break-in before carburetor adjustments can be made. During the break-

in period your engine performance will increase and exhaust emissions

will stabilize. Idle speed can be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting,

emission, and durability performance up to 1,100 feet mean sea level

(MSL) (96.0 kPa and below). To maintain proper engine operation and

emission compliance above 1,100 feet MSL the carburetor may need to

be adjusted by an authorized ECHO service dealer.

IMPORTANT

If the engine is adjusted for operation

above

1,100 feet MSL, the

carburetor must be re-adjusted when operating the engine

below

1,100 feet MSL, otherwise severe engine damage can result.

Level 2.

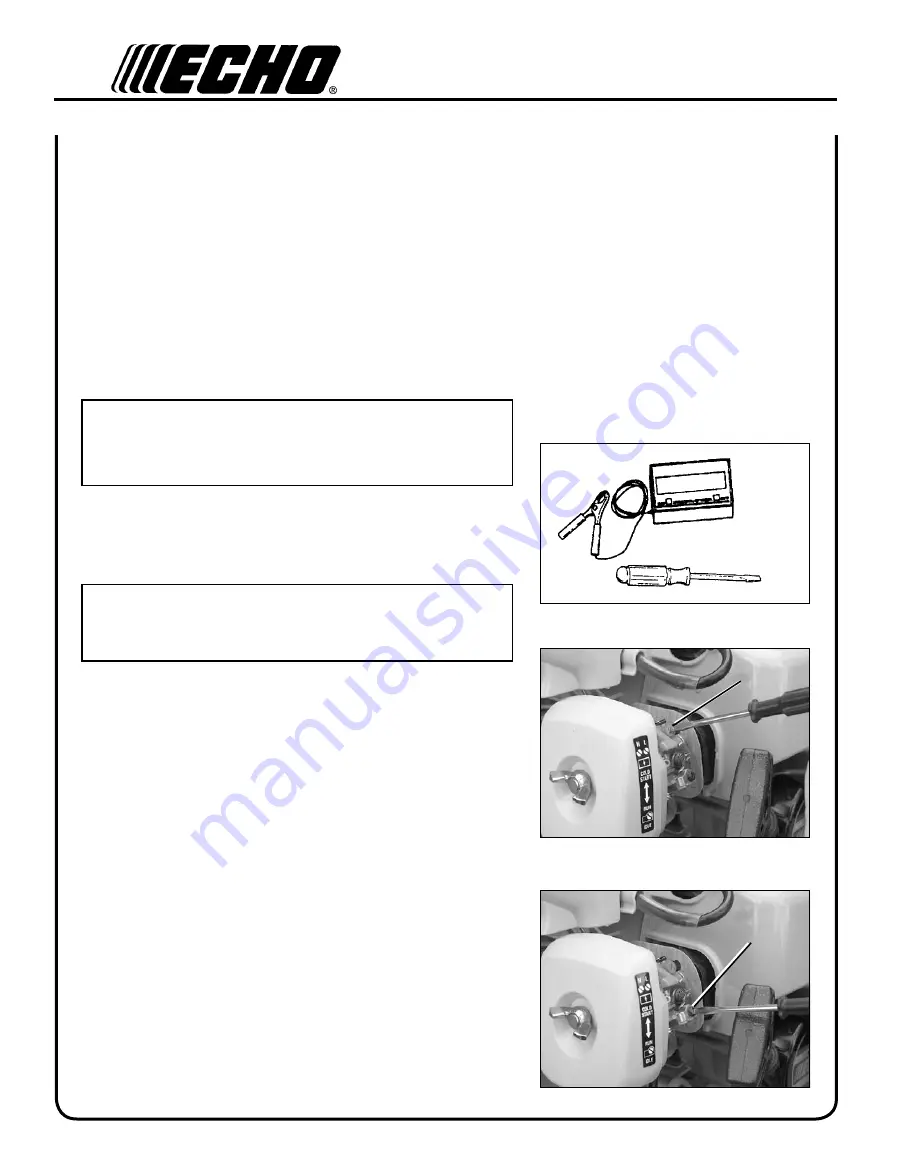

Tools required:

Screwdriver, tachometer (Echo P/N 99051130017)

Parts required:

None.

NOTE

Every unit is run at the factory and the carburetor is set in com-

pliance with emission regulations. This carburetor does not have

acceleration adjustment needle.

1. Before adjusting the carburetor, clean or replace the air filter and

spark arrestor screen and install blower pipes.

2. Start engine and run for several minutes to reach operating tem-

perature.

3. Stop engine. Turn red HI speed needle (A) CCW (counter clock-

wise) to stop.

4. Idle Speed Adjustment with tachometer.

•Start engine and turn “idle” speed adjustment screw (B) to idle

RPM found on page 24 “Specifications” section of this manual.

5. Accelerate to full throttle for 2-3 seconds to clear excess fuel from

engine then return to idle. Accelerate to full throttle to check for

smooth transition from idle to full throttle. If engine stops or

stalls after full warm up, return the unit to your authorized ECHO

dealer for repair.

6. Check HI speed RPM at W.O.T. (Wide Open Throttle). HI speed

RPM should be set to specifications found on page 24 “Specifica

-

tions” of this manual.

7. Check idle speed and reset if necessary.

A

b

Summary of Contents for ES-210 - 12-08

Page 26: ...26 notes ...