G

rass

T

rimmer

/B

rush

C

uTTer

7

O

peraTOr

'

s

m

anual

P/N X505001930

P/N X505002310

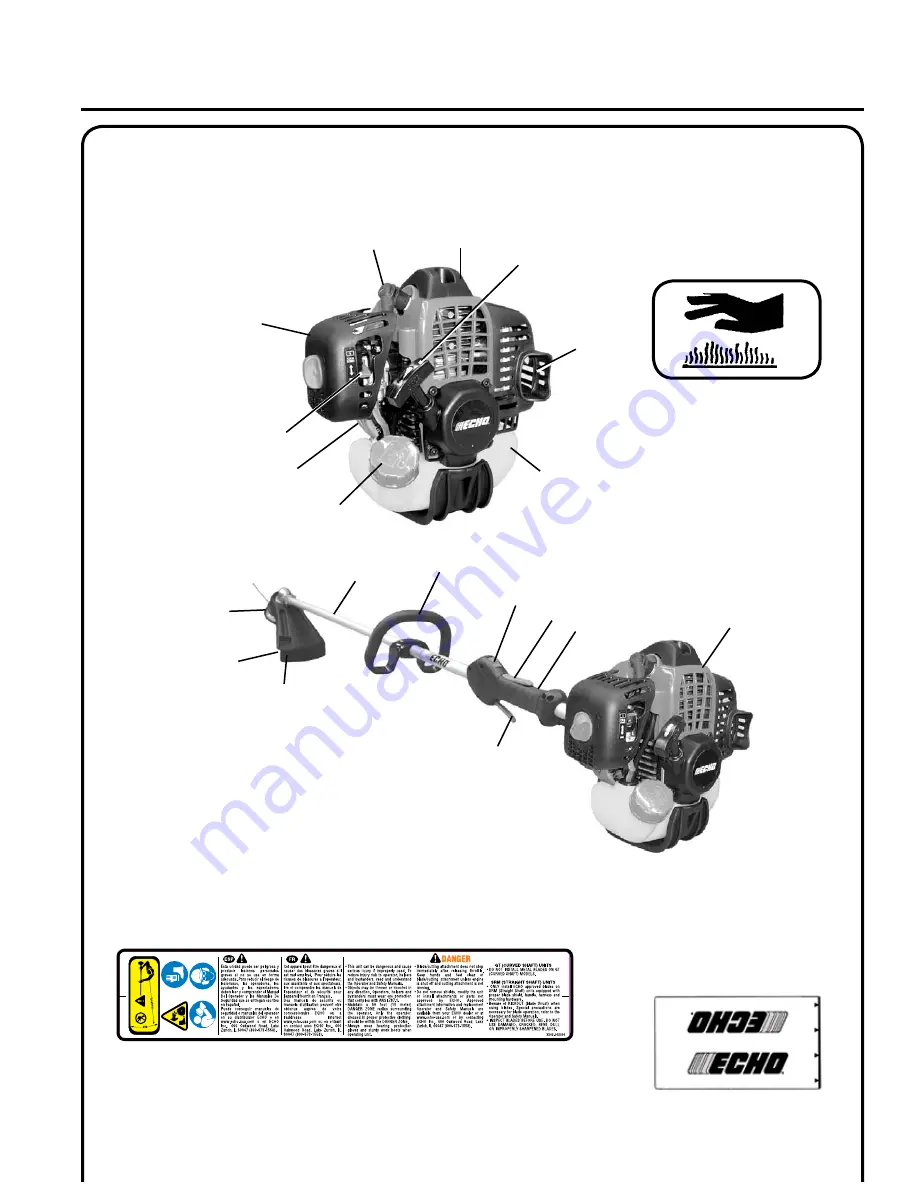

Hot Decal (near muffler)

d

escrIptIon

Locate these safety decals on your unit. Make sure the decals are legible and that you understand and follow the instruc-

tions on them. If a decal cannot be read, a new one can be ordered from your ECHO dealer. See PARTS ORDERING

instructions for specific information.

13

14

19

11

12

2

4

5

6

7

8

9

10

3

Shaft Decal

15

16

17

18

1

P/N X505002500