SERVICE INFORMATION

HCA-2500

9

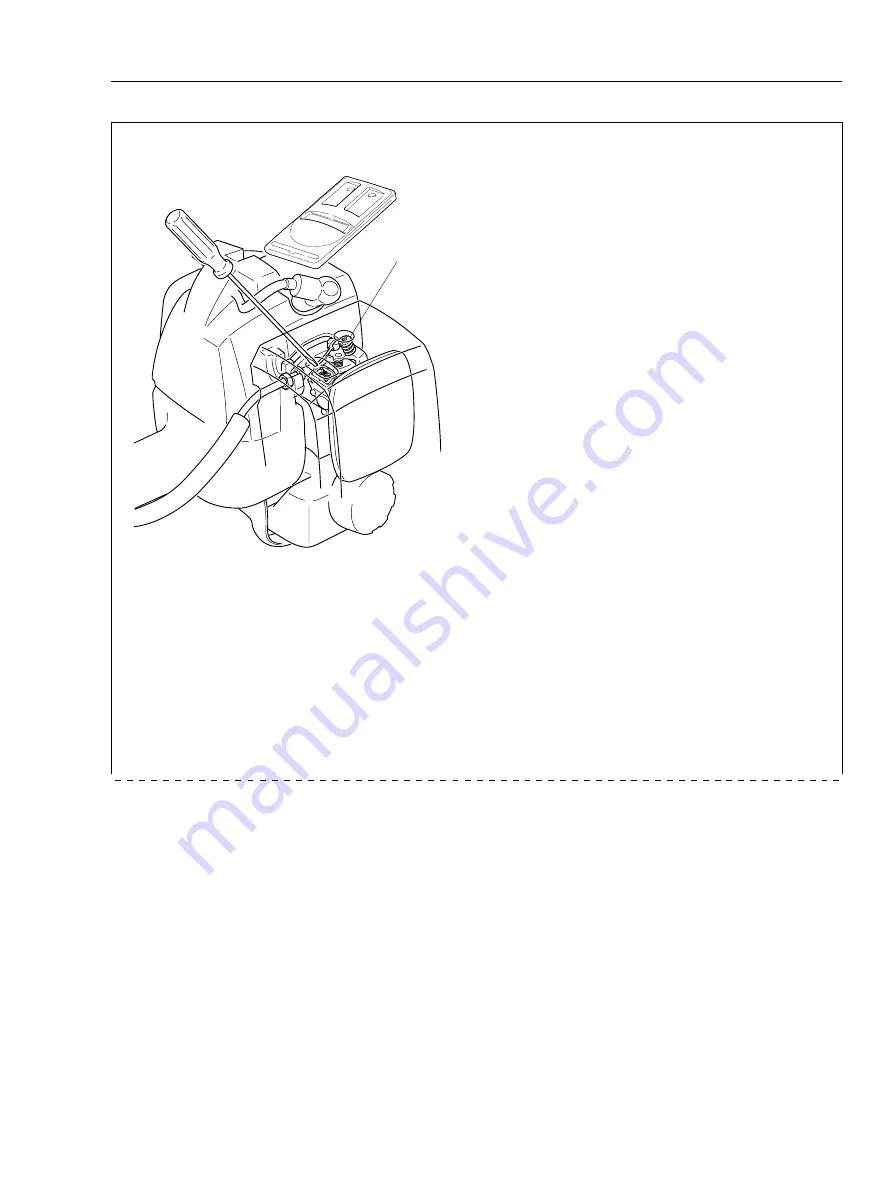

2-3 Adjusting carburettor

1. Start engine and warm it up alternating engine

speed between WOT and idle every 5 seconds for

1 minute.

2. Using 2.5 mm wide blade screw driver, adjust L

mixture needle to obtain maximum idle speed.

3. Set idle speed in the range of 3,400 to 3,500

r/min by turning idle adjust screw.

4. Turn L mixture needle anticlockwise to reduce

engine idle speed 700 to 800 r/min to set idle speed

in the range of 2,600 to 2,800 r/min.

NOTE : Engine speed must be allowed to stabilize

a minimum of 20 seconds after each adjustment of

L mixture needle to assure accurate tachometer

readings.

5. Turn H mixture needle anticlockwise to reduce

engine speed to approx. 9,000 r/min at WOT.

6. Turn H mixture needle clockwise to obtain 9,500

to 10,500 r/min at WOT.

NOTE : During H mixture needle adjustment, do not

run engine at high speed without load longer than

10 seconds.

7. If the engine speed at WOT is above 10,500

r/min, adjust H mixture needle anticlockwise and set

maximum engine speed at less than 10,500 r/min.

idle adjust screw

(Continued)