PAS-225SB

MAINTENANCE

© 10/2013 ECHO Inc.

X7722277600

21

MAINTENANCE

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects

away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts

have come to a complete stop before removing obstructions, clearing debris, or servicing unit.

Allow unit to cool before performing service. Wear gloves to protect hands from sharp edges and

hot surfaces.

Your ECHO unit is designed to provide many hours of trouble free service. Regular scheduled maintenance

will help your unit achieve that goal. If you are unsure or are not equipped with the necessary tools, you may

want to take your unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to

DO-IT-YOURSELF or have the ECHO Dealer do it, each maintenance task has been graded. If the task is

not listed, see your ECHO Dealer for repairs.

Skill Levels

Level 1

= Easy to do. Common tools may be required.

Level 2

= Moderate difficulty. Some specialized tools may be required.

ECHO offers

REPOWER

TM

Maintenance Kits and Parts to make your maintenance job easier.

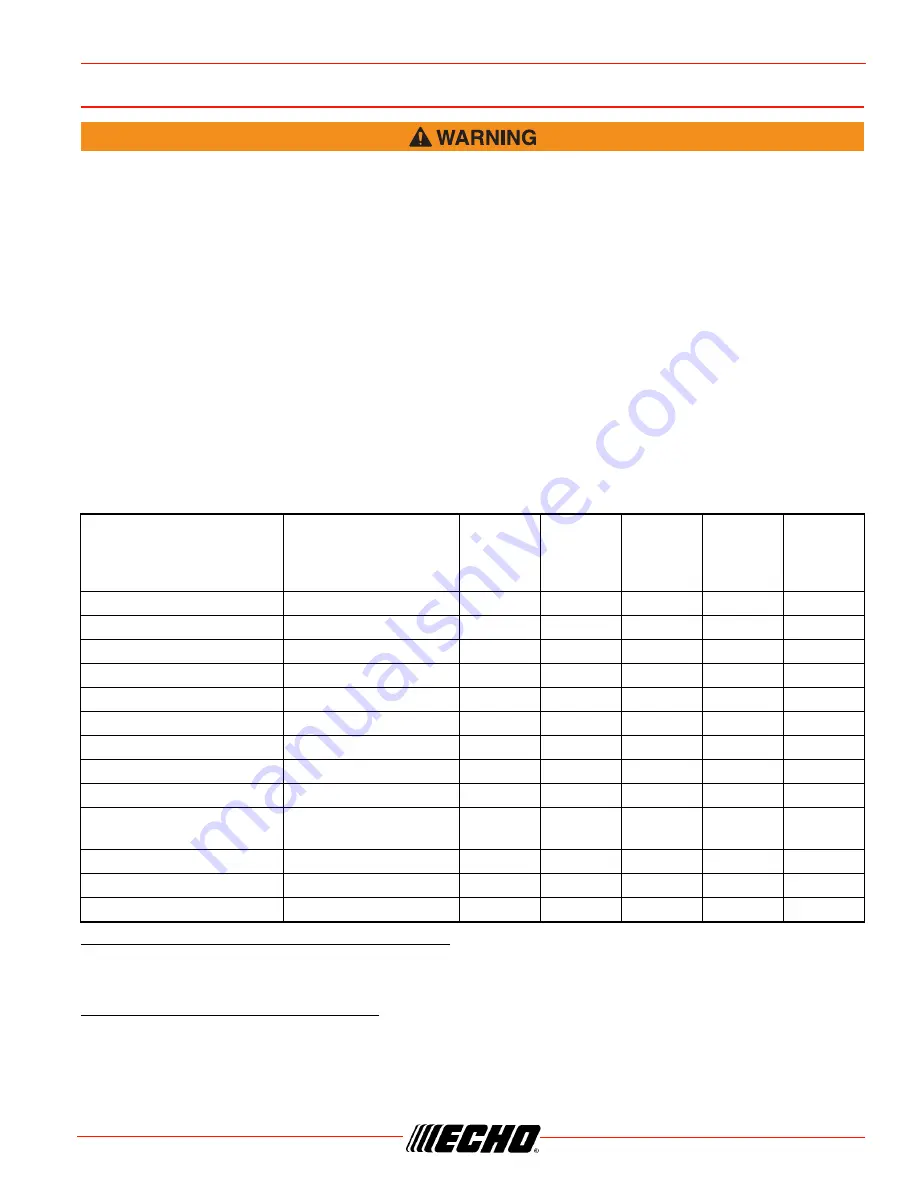

Maintenance Intervals

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE

- Time intervals shown are maximum. Actual use and your experience will determine

the frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Apply POWER BLENDX

TM

grease every 25 hours of use.

(2) Apply POWER BLENDX

TM

grease every 50 hours of use.

(3) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* Replacement is recommended based on the finding of damage or wear during inspection.

COMPONENT/SYSTEM

MAINTENANCE

PROCEDURE

REQ’D

SKILL

LEVEL

DAILY

OR

BEFORE

USE

EVERY

REFUEL

3

MONTHS

YEARLY

Air Filter

Inspect/Clean

1

I / C *

R *

Choke Shutter

Inspect/Clean

1

I / C

Fuel Filter

Inspect/Replace

1

I *

I / R *

Fuel Cap Gasket

Inspect/Replace

1

I *

R *

Fuel System

Inspect/Replace

1

I (3) *

I (3) *

Spark Plug

Inspect/Clean

1

I / C / R *

Cooling System

Inspect/Clean

2

I / C

Muffler Spark Arrestor

Inspect/Clean/Replace

2

I / C / R *

Cylinder Exhaust Port

Inspect/Clean/Decarbon

2

I / C

Drive Shaft

(Flex Cable Models)

Grease

2

I (1)

Gear Housing

Grease

2

I (2)

Recoil Starter Rope Inspect/Clean

1

I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace

1

I *