3

P

OWER

B

LOWER

O

PERATOR

'

S

M

ANUAL

IMPORTANT

The enclosed message provides

information necessary for the

protection of the unit.

NOTE

This enclosed message provides tips

for use, care and maintenance of the

unit.

Throughout this manual and on the product itself, you will find safety

alerts and helpful, informational messages preceded by symbols or key

words. The following is an explanation of those symbols and key

words and what they mean to you.

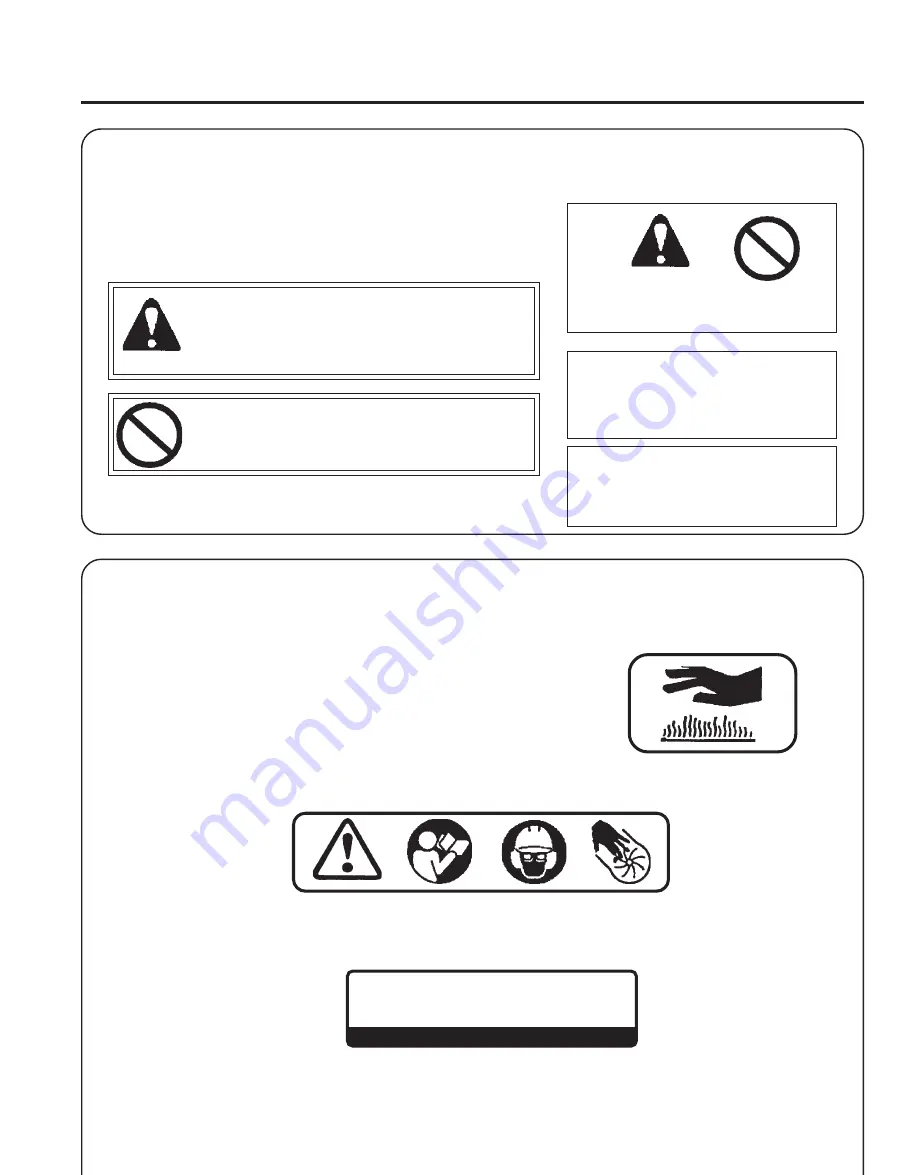

General Warning Decal (located on top of blower housing)

IMPORTANT

NOTE

P/N 89016006361

P/N 89016003360

67

Category II

dB(A)

Measured at 50 ft. (15m) per ANSI B175.2

P/N

X508000170

Sound Label (located on blower housing)

Hot Decal (near muffler)

M

ANUAL

S

AFETY

S

YMBOLS

AND

I

MPORTANT

I

NFORMATION

This symbol accompanied by the words WARNING and

DANGER calls attention to an act or condition that can lead to

serious personal injury to operator and bystanders.

The circle with the slash symbol means whatever is shown

within the circle is prohibited.

S

AFETY

DECALS

Locate these safety decals on your unit. Make sure the decals are

legible and that you understand and follow the instructions on them. If

a decal cannot be read, a new one can be ordered from your ECHO

dealer. See PARTS ORDERING instructions for specific information.