© 06/2020 ECHO Incorporated X7152270100

13

QUICK START GUIDE / GUÍA DE INICIO RÁPIDO / GUIDE DE DÉMARRAGE

RAPIDE

PAS-225 / PAS-2620

Pro Attachment Series

™

General

•

Debris flows in direction of line head rotation. Change line head position to

assure debris flow is directed away from operator.

• Keep cutting line away from wire fences to avoid entanglement.

• Operate trimmer only with cutting head below knee height.

Operating Techniques - metal or plastic blade

Brush cutter blades can be used to cut and trim a wide variety of matereials,

refer to the blade selection section for determining the correct blade for the

application.

Scything (3, 8, and 80 tooth weed/grass, and brush blades)

•

To cut large sections of field grass and weeds swing the cutting

head in a level arc, gradually feeding the blade into the material

being cut. Adjust throttle speed according to your work.

• Do not swing the main pipe with arms. Turn hips to swing the

blade horizontally from right to left, and cut weeds on the left

side of the blade.

• Do not scythe back and forth as the grass can scatter and

kickout can occur easily.

• Tilt blade left by 5 to 10 degrees so that cut grasses will push

left, making progress easier.

• Move forward with each arc to cut a swath.

• Width of cutting swath depends on arc. Use a larger arc for a

wider swath, or a smaller arc for a narrow swath. Suggested

cutting width is about 1.5 m (4.9 ft).

• When scything large brush up to 0.5” diameter from right to left,

avoid cutting with highlighted section.

Reaction Forces

• The cutting attachment will continue to rotate even after the throttle is

released, maintain control of the unit until it has come to a complete

stop.

• Blade thrust can occur when the spinning blade contacts an object

that it does not immediately cut. Following proper cutting techniques

will prevent blade thrust.

• Blade thrust can be violent enough to cause the unit and/or operator to

be propelled in any direction, and possibly lose control of the unit.

• Blade thrust can occur without warning if the blade snags, stalls or

binds.

•

Blade thrust is more likely to occur in areas where it is difficult to see

the material being cut.

Push or Pull - Kickout

During normal use, operating a brushcutter with a circular metal blade can

produce sudden strong reaction forces that are difficult to control. Strong

reaction forces can cause a loss of balance or loss of control of the equipment,

resulting in serious injury to operator and bystanders.

Understanding what causes these reactive forces can help you to avoid them,

and can help you to maintain control of the equipment if you experience a

sudden reaction during cutting. Reactive forces occur when the force being

applied by the cutting teeth of a blade meet resistance, and some of the cutting

force is directed back toward the equipment. The greater the cutting force or

the amount of resistance, the greater the reactive force.

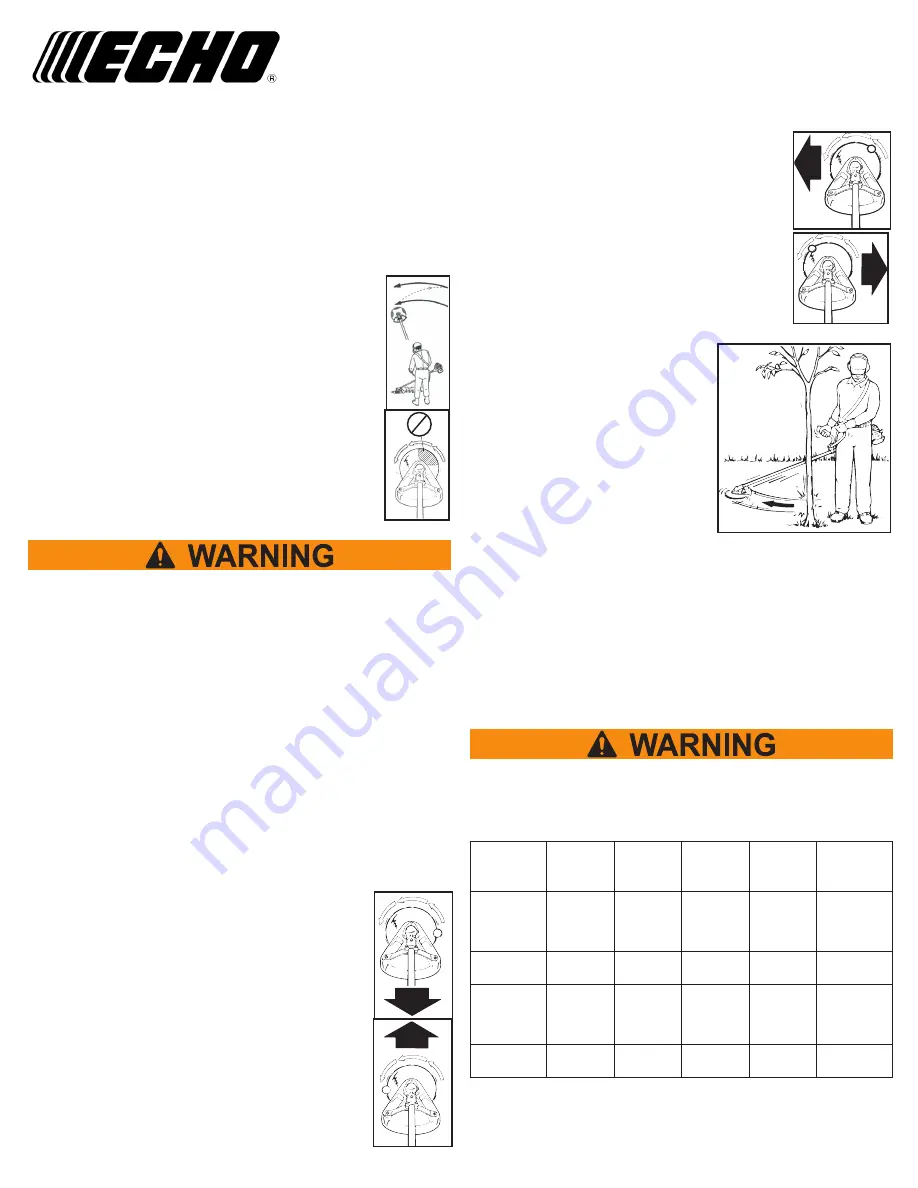

Push and Pull Forces

Push and pull forces are reactive forces that push the

equipment directly toward the operator, or that pull the

equipment directly away from the operator. These forces are

the result of cutting on the sides of the blade. The direction of

the force depends on the side of the blade being used, and the

direction of blade rotation at the point of contact. The reactive

force is in the opposite direction of blade rotation at the contact

point, regardless of where the contact is being made. These

types of reactive forces are also called “Blade Thrust.”

As shown in the illustration, a blade turning counterclockwise

will cause the equipment to pull away from the operator if the

point of cutting resistance is on the left side of the blade. If

the point of cutting resistance is on the right side of the blade,

the equipment will push back toward the operator. In both

examples, the reactive force is in the opposite direction of

blade rotation at the contact point where resistance occurs.

Kickout

Kickout is also a reactive force caused by resistance to

cutting, but the direction of blade thrust is lateral (to the left

or right of the blade), instead of forward or back toward the

operator. In most cases, Push, Pull, and Kickout can be

reduced or eliminated by:

• Using the correct blade for the cutting job.

• Using properly sharpened blades.

• Applying consistent, even force to the blade during the

cut.

• Avoiding obstacles and ground hazards.

• Using extra care when cutting harder materials such as

extremely dry brush, saplings, and small trees.

• Cutting from a stable, secure position.

Blade Cutting Problems

Binding - Blades can bind in the cut if dull

or forced. Binding can damage blade, and

result in blade breakage or injury from

fragments and flying debris. If a blade binds

in a cut, don’t try to get it out by applying

“up and down” force to pry the cut open.

Applying prying force to the blade can bend

the blade, and result in blade failure and

injury.

To free a blade that is bound in the cut,

stop the engine, and support the trimmer

or brushcutter to keep stress off the blade.

Push the tree away from the entry point of

the cut to open the cut, and pull the blade

directly away from the cut in a straight-line

motion. Use caution when releasing the tree to avoid being struck by spring-

back or falling.

Inspect the blade for damage before proceeding. Sharpen teeth if dull, or

replace blade if cracked, bent, missing teeth, or otherwise damaged.

To prevent binding:

• Keep blades sharp.

• Avoid excessive pressure during cuts.

• Don’t exceed cutting capacity of blade.

• Don’t use blades with damaged or missing cutting teeth.

• Don’t rock blades in cut.

Operation With Blades

Metal blades are very sharp and can cause severe injuries, even if

engine is off and blades are not moving. Avoid contact with blades. Wear

gloves to protect hands.

Blade use demands specific brush cutter configuration. Operation

without specified shield, barrier bar or U-handle, and harness can result

in serious personal injury. Follow installation instructions.

Material

to be

Cut

Grass Weed/

Grass

Weed/

Grass

Brush

(<0.5”)

Clearing

(<2.5”)

Cutting

Attachment

Nylon

line head

Included

Maxi-Cut

head,

Pro Maxi-

Cut head

3 Tooth

Blade,

8 Tooth

Blade

80 Tooth

Blade

22 Tooth

Blade

Shield

Shield

Included

Included

with unit

Included

with unit

Included

with Blade

Included with

Blade

Handle

Handle

Included

U-Handle*

or Support

Handle w/

Barrier Bar

U-Handle*

or Support

Handle w/

Barrier Bar

U-Handle*

or Support

Handle w/

Barrier Bar

U-Handle*

or Support

Handle w/

Barrier Bar

Harness

Not

Required

Not

Required

Supplied

w/Kit

Supplied

w/Kit

Supplied

w/Kit

*ANSI standards require brushcutters be equipped with a barrier bar or

restrictive harness. U-Handle ensures a higher safety factor.