FUEL SYSTEM

CSG-7410ES

EC741S

27

A

B

A

D

F

E

G

H

J

a

K

J

K

4-6 Inspecting tank vent

NOTE:

Tank vent prevents a vacuum from forming in fuel tank when fuel in fuel tank is being consumed.

When pressure in fuel tank becomes too high, tank vent releases the pressure.

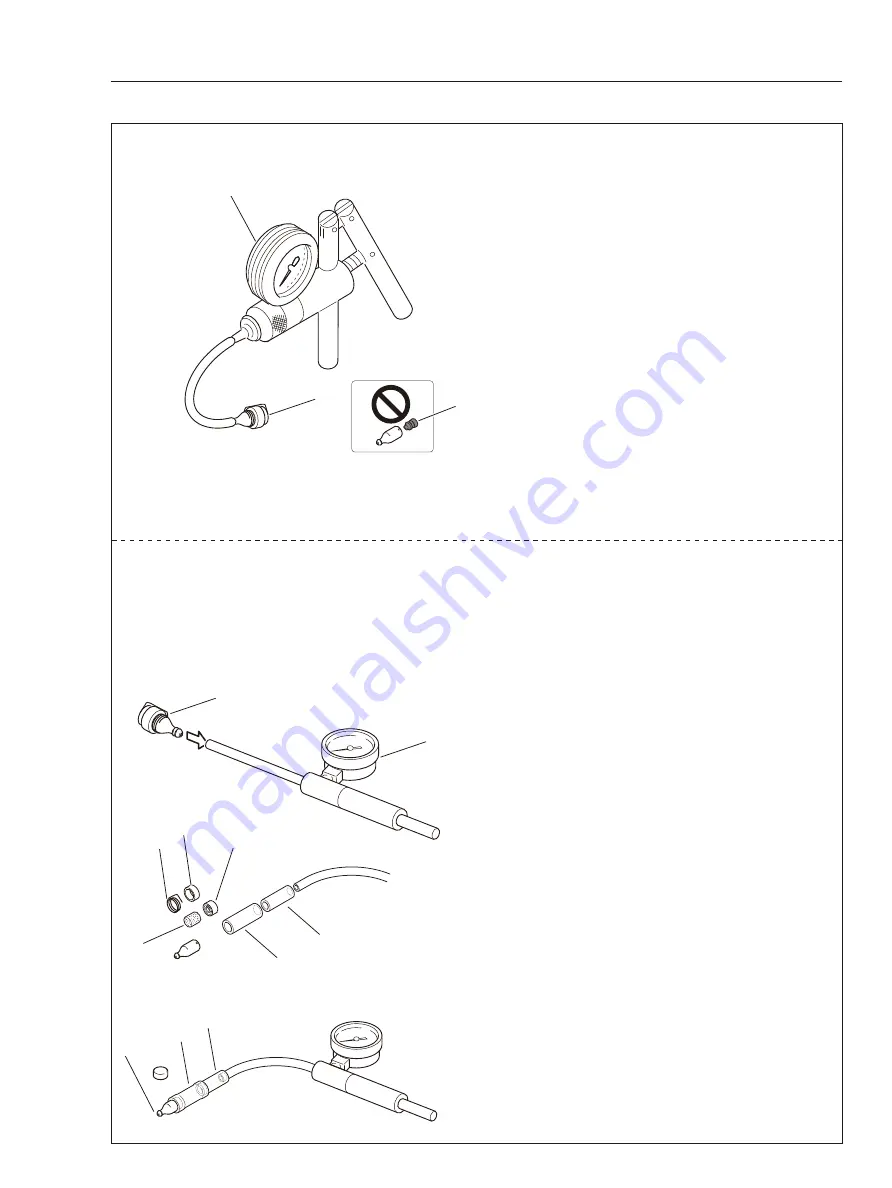

Inspection using Pressure / vacuum tester 91149

1. Remove tank vent (A) from rear handle (Refer to

“4-5 Disassembling carburetor, fuel line and tank

vent).

2. Connect Pressure / vacuum tester 91149 (B) to

tank vent (A).

3. Apply pressure approx. 0.05 MPa (0.5 kgf/cm

2

) (7

psi). Make sure pressure is stable in range of 0.01

- 0.04 MPa (0.1 - 0.4 kgf/cm

2

) (1.4 - 5.7 psi).

4. If it is not in the range, gently clean tank vent (A)

with compressed air or replace with new one.

NOTE:

Do not disassemble valve in tank vent as-

sembly. Damage to valve will occur.

5. Apply negative pressure 0.02 MPa (0.2 kgf/cm

2

) (3 psi).

6. Tank vent should pass air freely without holding any pressure. If it does not, replace tank vent with new one.

Inspection using Pressure tester 897803-30133

If Pressure / vacuum tester 91149 is not available,

tank vent can be inspected with Pressure tester

897803-30133 as follows.

1. Connect tank vent (A) to Pressure tester

897803-30133 (D).

2. Apply pressure approx. 0.05 MPa (0.5 kgf/cm

2

) (7

psi), make sure pressure is stable in range of 0.01

- 0.04 MPa (0.1 - 0.4 kgf/cm

2

) (1.4 - 5.7 psi).

3. If it is not in the range, gently clean tank vent

with compressed air or replace with new one.

NOTE:

Do not disassemble valve in tank vent as-

sembly as shown. Damage to valve will occur.

4. Remove wire (E), filter (F) and cap (G) from tank

vent and clean sponge (H).

5. Cut pipe 363011-00210 (J: 7x11x170mm) and

382011-01110 (K: 9x13x350) in approx. 30mm (1

1/4 in) length, and connect them to pressure tester

as shown. Connect tank vent without cap to pipe

as shown.

6. Plug hole (a) with finger and apply pressure 0.2

MPa (0.2 kgf/cm

2

) (3 psi). The pressure should

hold steady.

7. Remove finger from hole (a). Tank vent should

pass air freely without holding any pressure. If it

does not, replace tank vent with new one.

valve