G

RASS

T

RIMMER

/B

RUSH

C

UTTER

O

PERATOR

'

S

M

ANUAL

15

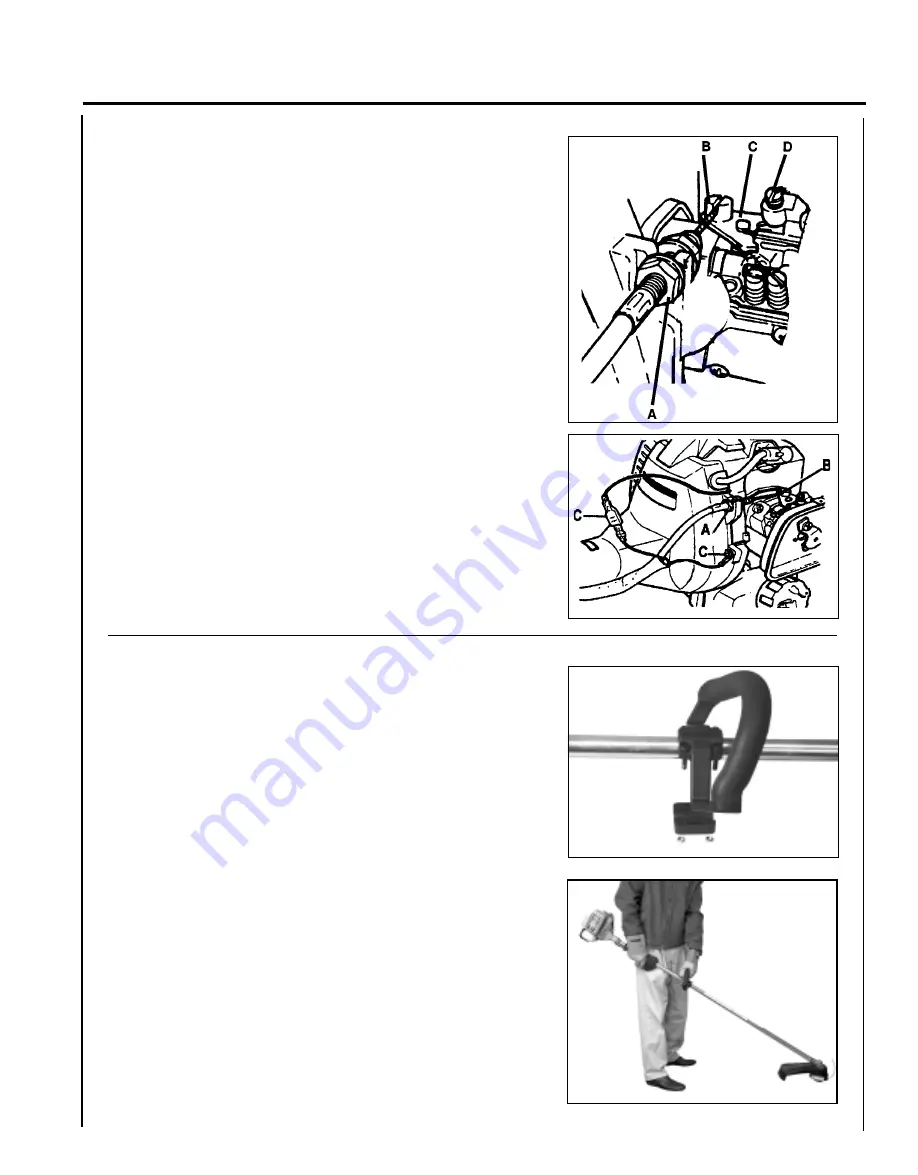

THROTTLE

LINKAGE

AND

IGNITION

LEADS

Tools Required: 8mm x 10mm open end wrench (all models), 3mm Allen

Wrench.

1. Close choke and remove air filter cover.

2. Loosen nut (A) and place threaded end of throttle linkage in

bracket slot. Finger tighten nut (A).

3. Place inner cable in slot of carburetor swivel (B) and tighten

nut (A).

4. Check throttle for freedom of movement and make sure it returns

to idle position. If the throttle linkage does not allow the carbure-

tor throttle plate (C) to return to idle against idle screw (D),loosen

linkage nuts; turn throttle linkage nut (A) counter clock

wise

until throttle plate (C) just rests against idle screw (D). Hold

linkage nut (A) from turning and tighten other linkage nut.

5. Connect ignition leads (C). SRM-2100 has one connector

terminal pair and one ring terminal which attaches under fan

terminal screw (C).

6. Install air filter and cover.

FRONT

HANDLE

INSTALLATION

Tools Required: Screwdriver.

Parts Required: Front Handle, Handle Support, Four (4) 5mm x 35mm

screws with captivated washers, four (4) 5mm nuts.

1.

Position front handle for comfortable operation and secure screws.

Summary of Contents for SRM-2100 - PARTS CATALOG SERIAL NUMBER 001001 THRU 159490

Page 2: ......

Page 33: ...GRASS TRIMMER BRUSH CUTTER OPERATOR S MANUAL 33 NOTES ...

Page 34: ...34 NOTES ...

Page 35: ...GRASS TRIMMER BRUSH CUTTER OPERATOR S MANUAL 35 NOTES ...