G

rass

T

rimmer

/B

rush

C

uTTer

O

peraTOr

'

s

m

anual

9

c

ontents

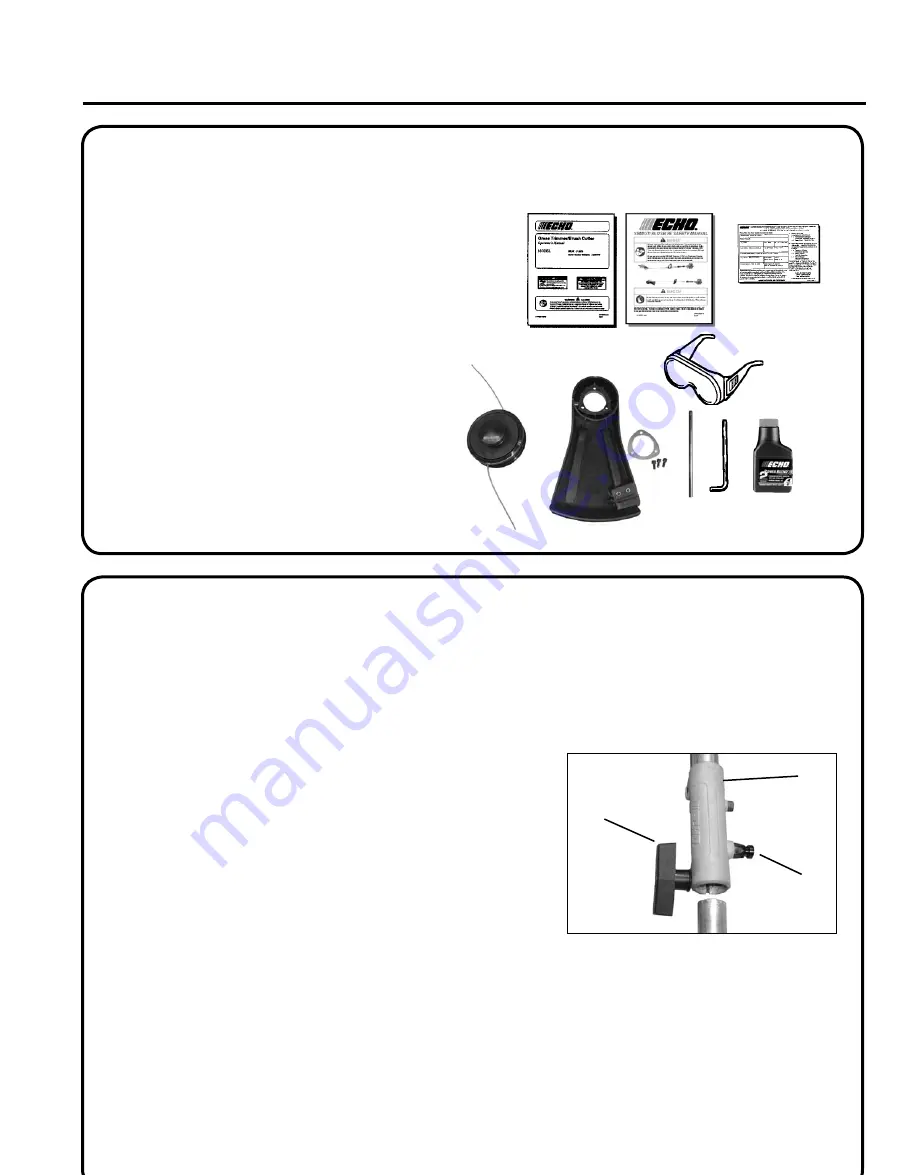

After opening the carton, check for damage. Immediately notify your retailer or ECHO Dealer of damaged or missing

parts. Use the contents list to check for missing parts.

_____ 1 - Power Head w/Upper Drive Shaft Assembly

_____ 1 - Lower Drive Shaft Assembly

____ 1 - Operator's Manual

____ 1 - Safety Manual

___ 1 - Warranty Registration Card

____ 1 - Plastic shield

____ 1 - Shield plate

____ 3 - 5 mm x 16 mm screws (shield mounting)

____ 1 - Locking tool

____ 1 - Nylon Trimmer Head

_____ 1 - T27 Torx L-Wrench

____ 1 - Safety Glasses

____

1

-

Echo Power BlendX

TM

2-stroke oil sample

a

ssembly

power

head

shaft

/

lower

shaft

assembly

D

a

B

Tools Required:

None

Parts Required:

Split Boom Attachment Assembly

1. Set Power Head/Shaft Assembly on a level surface.

2. Pull locator pin (A) out, and turn counter-clockwise 1/4 turn to lock-

out position.

3. Remove vinyl cap from attachment drive shaft.

4. Remove cardboard spacer, if necessary.