G

RASS

T

RIMMER

/B

RUSH

C

UTTER

O

PERATOR

'

S

M

ANUAL

25

C

D

D

5.

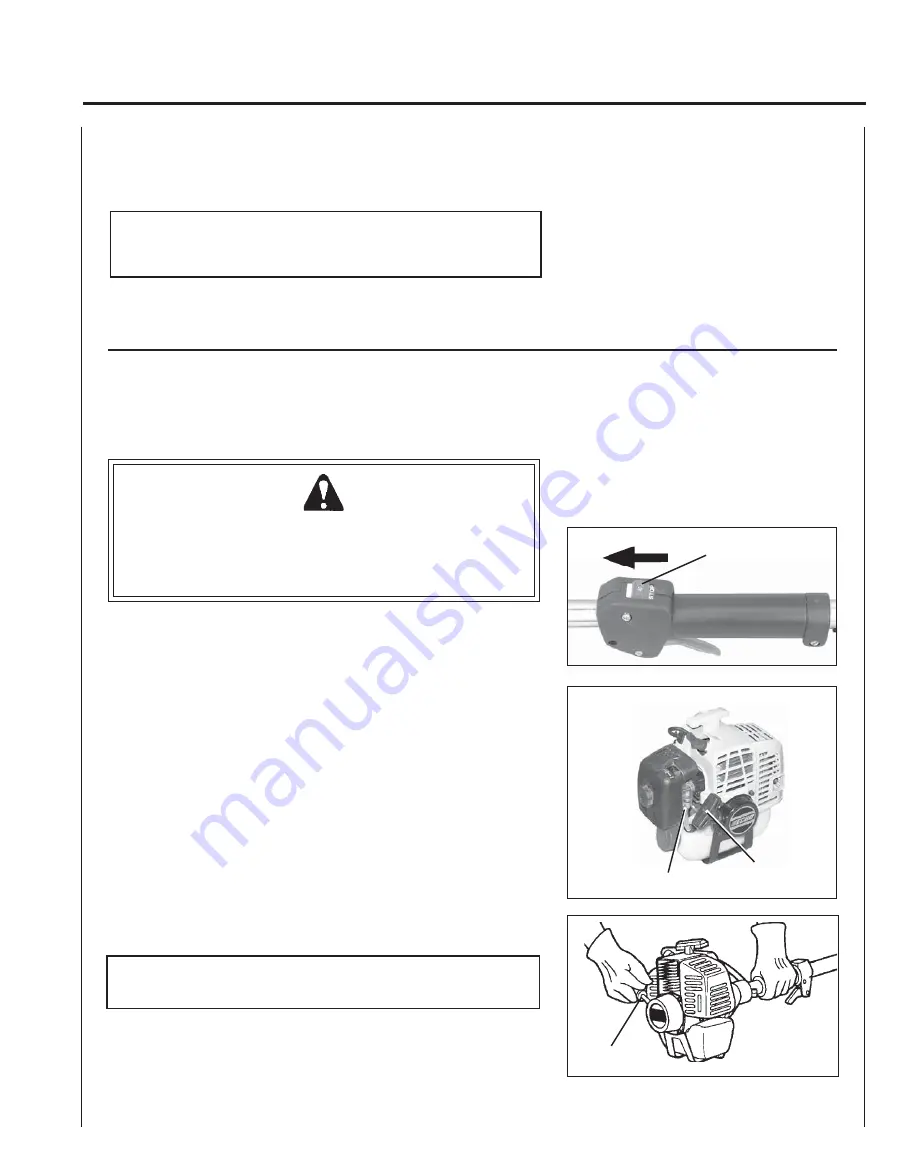

Open Choke

- Run.

Move the choke lever back to the OPEN - RUN position. Restart

engine if necessary and allow to warm up running at idle for several

minutes.

NOTE

If engine does not start with choke in “Run” position after 4 pulls,

repeat instructions.

6.

After engine warm up, gradually depress throttle trigger to increase

engine RPM to operating speed.

STARTING

WARM

ENGINE

The starting procedure is the same as Cold Start except DO NOT close

the choke.

WARNING DANGER

The cutting attachment should not rotate at idle. If attachment

rotates, readjust carburetor according to "Carburetor Adjustment"

instructions in this manual or see your ECHO Dealer, otherwise

serious personal injury may result.

1.

Stop Switch - Start/Run. Move Stop Switch button (A) forward

away from the STOP position.

2.

Primer

-

Pump Bulb.

Pump primer bulb (C) until fuel is visible

in the "Clear" fuel return line.

3.

Start - Pull Rope.

Lay the trimmer on a flat clear area and pull

the recoil starter handle (D) until the engine fires.

NOTE

If engine does not start after 4 pulls, use Cold Start Procedure.

A