20

1.

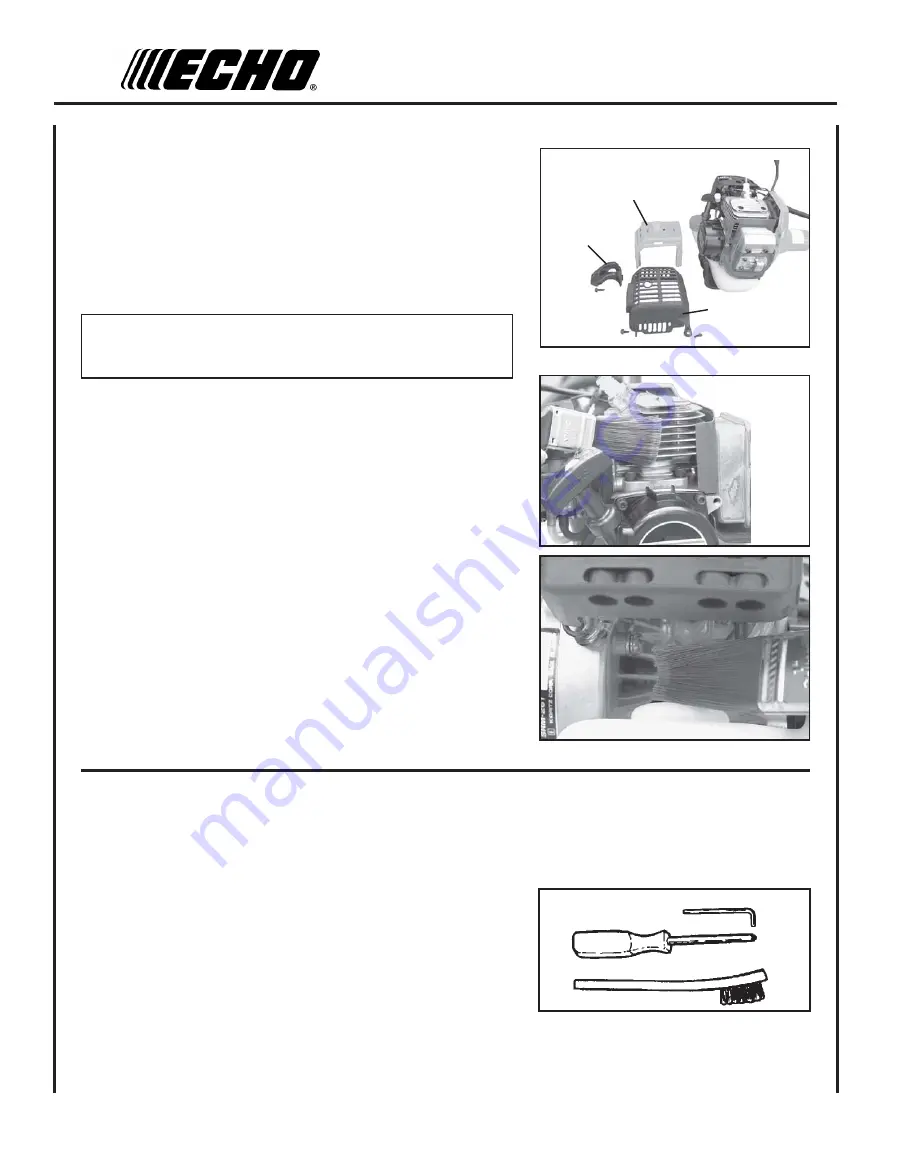

Remove spark plug lead.

2.

Remove two (2) muffler cover screws and muffler cover (A).

3.

Remove screw and arm rest (B).

4.

Remove engine cover (C).

IMPORTANT

DO NOT use a metal scraper to remove dirt from the cylinder fins.

5.

Use brush to remove dirt from the cylinder fins.

6.

Remove grass and leaves from the grid between the recoil starter

and fuel tank.

7.

Assemble components in reverse order.

EXHAUST

SYSTEM

Spark Arrestor Screen

Level 2.

Tools Required: Cross Head Screwdriver, Soft Metal Brush, 4 mm Hex

Wrench

Parts Required: Spark Arrestor Screen, Gasket

A

B

C