G

RASS

T

RIMMER

/B

RUSH

C

UTTER

O

PERATOR

'

S

M

ANUAL

11

S

PECIFICATIONS

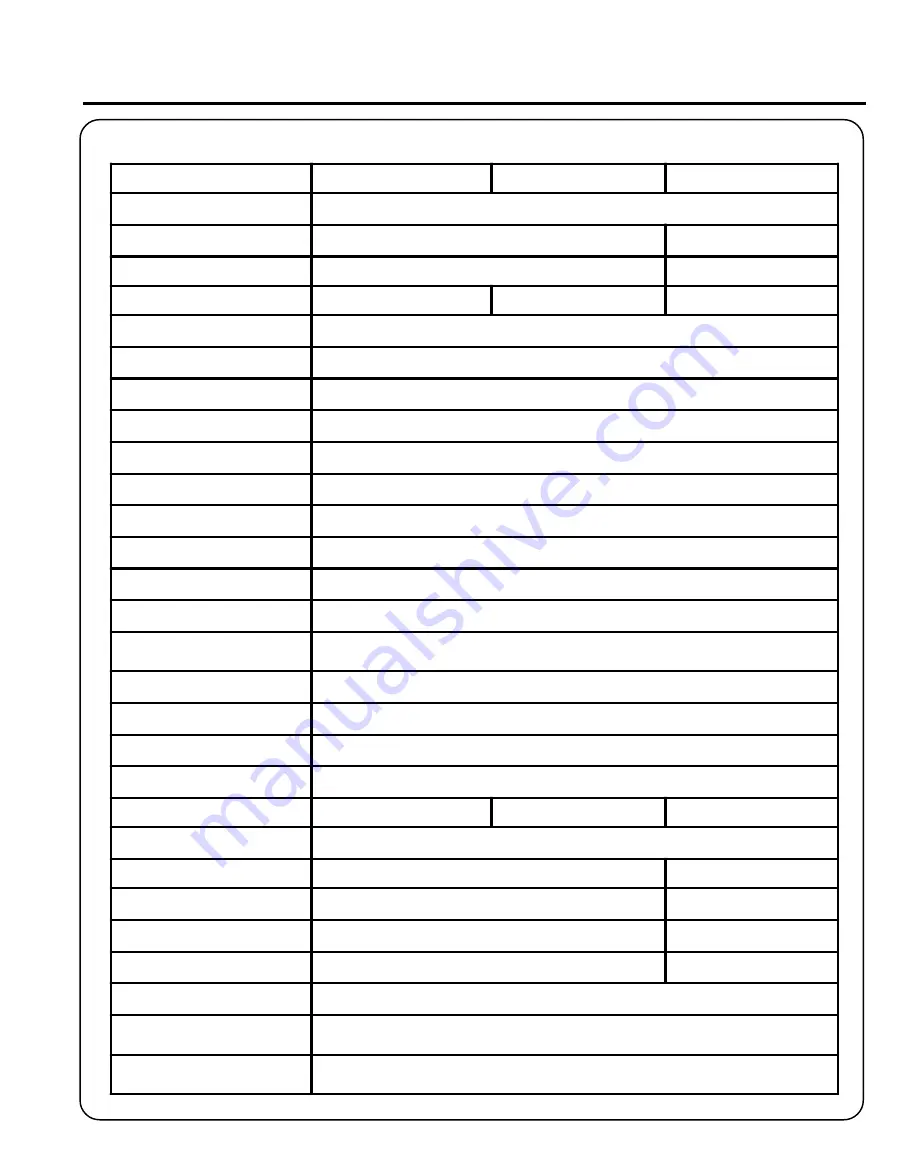

* Install and use U-Handle when operating any model with blade.

M O D E L

S R M -3 1 1

S R M -3 1 1 S

S R M -3 1 1 U

L e n g th

1 8 2 0 m m (7 1 .7 i n .)

W i d th

2 5 0 m m (9 .8 i n .)

7 1 0 m m (2 8 .0 i n .)

H e i g h t

2 6 0 m m (1 0 .0 i n .)

4 2 0 m m (1 6 .5 i n .)

W e i g h t (d r y) w /C u tte r H e a d

6 .0 k g (1 3 .2 lb .)

6 .1 k g (1 3 .4 lb .)

6 .5 k g (1 4 .3 lb .)

E n g i n e Typ e

A i r c o o le d , tw o -s tro k e , s i n g le c yli n d e r g a s o li n e e n g i n e

B o re

3 6 .0 m m (1 .4 2 i n .)

S tro k e

3 0 .0 m m (1 .1 8 i n .)

D i s p la c e m e n t

3 0 .5 c c (1 .8 6 c u . i n .)

E xh a u s t

S p a rk A rre s to r M u ffle r w /c a ta lys t

C a r b u re to r

W a lb ro d i a p h r a g m m o d e l W YJ w /p u rg e p u m p

Ig n i ti o n S ys te m

F lyw h e e l m a g n e to , c a p a c i to r d i s c h a rg e (C D I)

S p a rk P lu g

N G K B P M -8 Y, (G a p 0 .6 5 m m (0 .0 2 6 i n .)

F u e l

M i xe d (G a s o li n e a n d Tw o - s tro k e O i l)

F u e l/O i l R a ti o

5 0 :1 E C H O H i g h P e r fo r m a n c e , tw o - s tro k e a i r c o o le d e n g i n e o i l

G a s o li n e

8 9 O c ta n e u n le a d e d . D O N O T u s e fu e l c o n ta i n i n g m e th yl a lc o h o l, m o re th a n

1 0 % e th yl a lc o h o l o r 1 5 % M T B E .

O i l

5 0 :1 E C H O H i g h P e r fo r m a n c e , tw o - s tro k e a i r c o o le d e n g i n e o i l

F u e l Ta n k C a p a c i ty

0 .9 li t. (3 0 .4 U S fl. o z.)

S ta rte r S ys te m

A u to m a ti c R e c o i l S ta rte r

C lu tc h

C e n tri fu g a l Typ e

D r i ve S h a ft

1 /4 " F le x S h a ft

7 m m S p li n e S te e l S h a ft

1 /4 " F le x S h a ft

R o ta ti n g D i re c ti o n

C o u n te r C lo c k w i s e vi e w e d fro m to p

C u tte r H e a d

S e m i A u to N ylo n li n e h e a d ( 2 -li n e )

B la d e C a p a b le

H a n d le s *

F r o n t-L o o p , R i g h t G ri p

U -H a n d le

U -H a n d le

O p ti o n a l k i t

S ta n d a rd

S h o u ld e r H a rn e s s

S ta n d a rd H a rn e s s

H a rn e s s w /h i p p a d

Id le S p e e d

2 5 0 0 - 3 3 0 0 R P M

W i d e O p e n T h ro ttle S p e e d

(W .O .T.) w i th N ylo n L i n e H e a d

8 5 0 0 - 9 5 0 0 R P M

W i d e O p e n T h ro ttle S p e e d

(W .O .T.) w i th B la d e

9 5 0 0 - 1 1 0 0 0 R P M

Summary of Contents for SRM - 311

Page 2: ......

Page 31: ...GRASS TRIMMER BRUSH CUTTER OPERATOR S MANUAL 31 NOTES...