Installation and Startup of Combi Gateway

40

Version 1.6 04. November 2016

6.7

Checklist for the putting into service

Page 1/3

Store: _____________________________

Location _____________________________

Postcode

_______________________________

Street _____________________________

Telephone

_______________________________

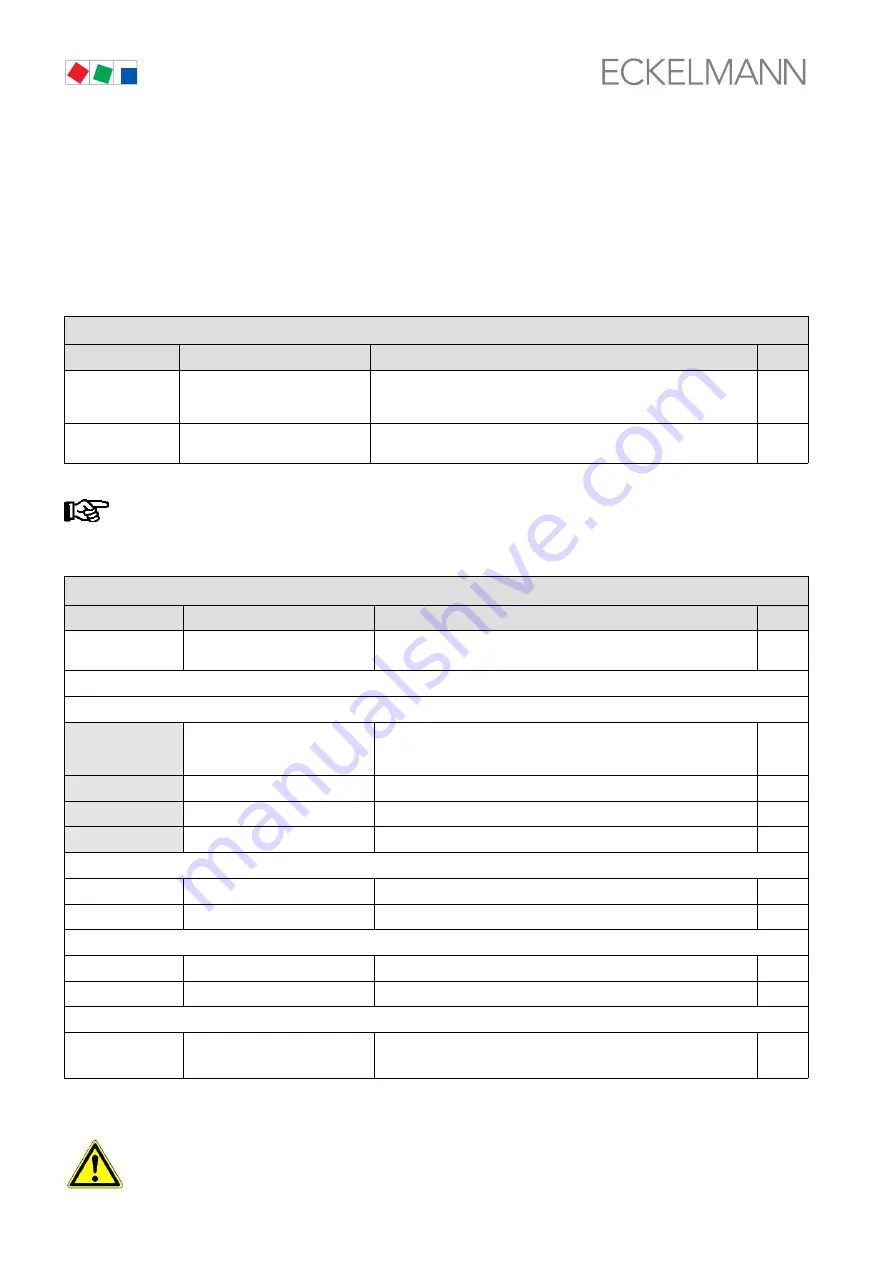

1. E*LDS System - CAN bus connections

Module

Measure / test

Note / settings

Status

CAN-Bus at

store computer

CAN bus termination (terminating

resistor 100 Ohm) checked?

For information about the CAN bus, see the operating manual

”Basics and general safety and connection instructions”, see

https://edp.eckelmann.de/edp/lds/_0sErd44C8T

CAN-Bus at

Combi Gateway

Correct CAN bus-termination,

see chapter 6.2?

Check DIP switch CAN Term 1 resp. CAN Term 2

The following three pages must be completely filled in to backup all settings of the Combi Gateway.

All required parameters (here the factory settings) must be checked on the web-based configuration

interface (see chapter 6.6) and documented here.

2. Combi Gateway

Module

Measure / test

Note / settings

Status

Status LEDs

Status LEDs checked?

7-segment display cycles ->

connection to the store computer is present

Global Settings

Net work

Hostname

1)

Hostname configured?

(called „Compter name“

in the field mask)

Combi-Gateway

IP address

1)

Configured?

192.168.161.66

Subnet mask

1)

Configured?

255.255.255.0

Default gateway

1)

Configured?

192.168.161.1

COM Port Server

TCP port

Configured?

1041

Baud rate

Configured?

38400

Language and time

Language

Configured?

Deutsch (German)

Time zone

Configured?

UTC+01:00 - Europe/Berlin

Security

Access details

Modification of the access details

User name::

webadmin

Password: FanTubo3

New: _____________________

1)

For the configuration file required settings, see chapter 6.5.1.1.

Unauthorized access protection!

The new password should be kept securely against access by

unauthorised persons!

Summary of Contents for Combi

Page 1: ...Version 1 6 04 November 2016 Operating instruction Combi Gateway Version V1 57 ...

Page 6: ...iv Version 1 6 04 November 2016 Notice ...

Page 18: ...Application Combi Gateway 12 Version 1 6 04 November 2016 Notice ...

Page 54: ...Decommissioning and disposal 48 Version 1 6 04 November 2016 Notice ...

Page 58: ...Order No s and accessories 52 Version 1 6 04 November 2016 Notice ...