9

Eclipse AirHeat Burner, V2, Design Guide 135, 6/16/2010

Step 4: Ignition System

Ignition Transformer

For the ignition system, use a transformer with:

• secondary voltage 6000 to 8000 VAC

• minimum secondary current 0.02 amp continuous

• full wave output

DO NOT USE

the following:

• twin outlet transformer

• distributor type transformer

Trial For Ignition

It is recommended that low fire start be used. However,

under certain circumstances AirHeat burners are capable

of direct spark ignition at higher gas inputs.

Most local safety codes and insurance requirements limit

the maximum trial for ignition time (the time it takes for a

burner to ignite). These requirements vary from one

location to another; check your local codes and comply to

the strictest codes applicable.

The time it takes for a burner to ignite depends on the

following:

• the distance between the gas shut-off valve and the

burner.

• the gas flow conditions at start-up.

The possibility exists where the low fire is too low to ignite

the burner within the maximum trial for ignition time. The

following options must be considered under these

conditions:

• start at higher gas input levels.

• resize and/or relocate the gas controls.

• use spark ignited pilot.

Ignition Gas Piping

AirHeat burners are capable of ignition with either direct

spark or spark ignited pilot.

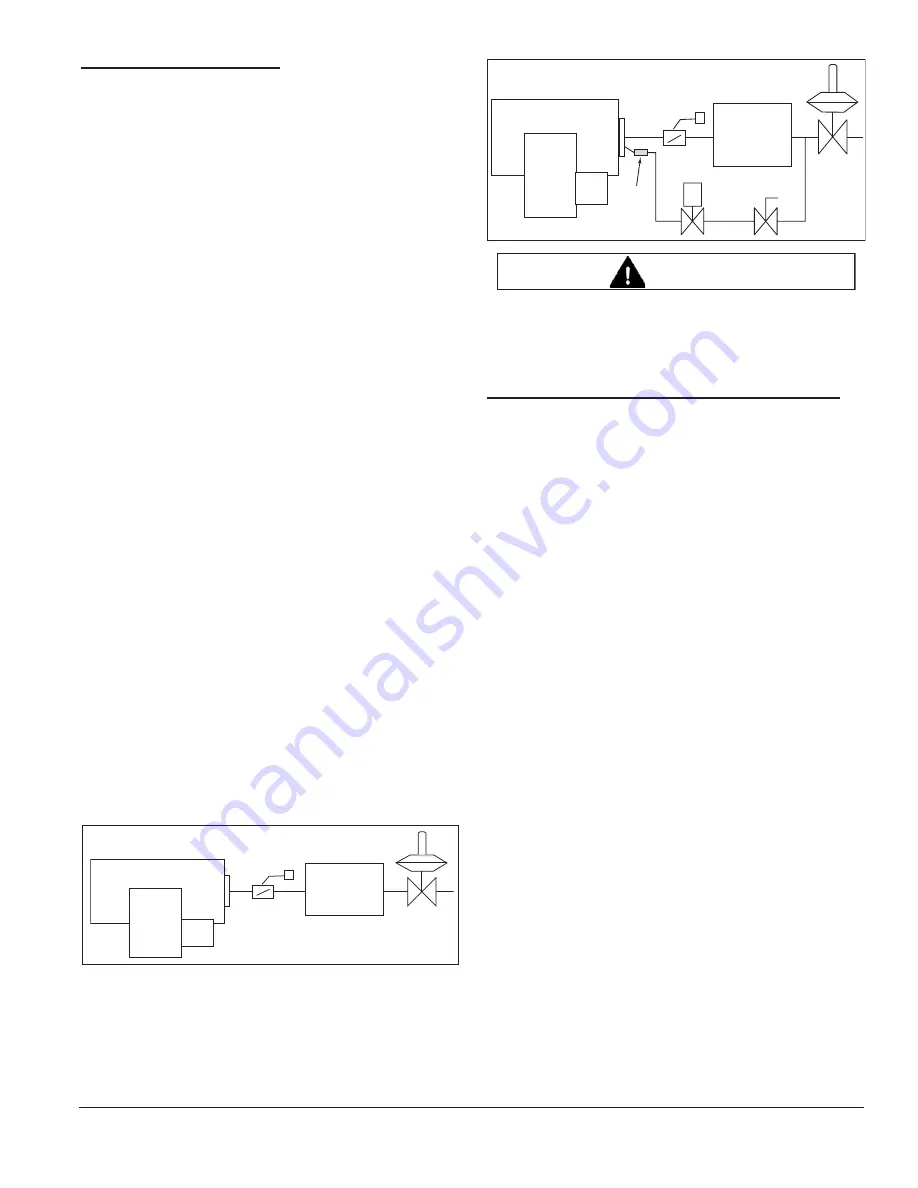

Direct Spark Ignition

Spark Ignited Pilot

When ordered, the pilot is packaged with the burner and

includes an adjustable flow gas cock and pressure

regulator.

Ŷ

It is not possible to use a continuous or

intermittent pilot. The pilot fuel flow should be

interrupted after the trial ignition period has

expired.

Step 5: Flame Monitoring Control System

The flame monitoring control system consists of two main

components:

• flame sensor

• flame monitoring control

Flame Sensor

Two types can be used on AirHeat Burners:

• flame rod

• UV scanner

The UV scanner must be compatible to the flame

monitoring control that is used. Refer to the manual of

your selected control for proper selection of the scanner.

Flame Monitoring Control

The flame monitoring control processes the signal from

the flame sensor and controls the start-up and shut-down

sequences.

Eclipse recommends the following flame monitoring

controls:

• Trilogy series T400 (Instruction Manual 830)

• Veri-Flame series 5600 (Instruction Manual 818)

• Bi-Flame series 6500 (Instruction Manual 826)

• Multi-Flame series 6000 (Instruction Manual 820)

If other controls are considered, contact Eclipse to

determine how burner performance may be affected.

Flame monitoring controls that have lower sensitivity

flame detecting circuits may limit burner turndown and

change the requirements for ignition.

Flame monitoring controls that stop the spark as soon as

a signal is detected may prevent establishment of flame,

particularly when using UV scanners. The flame

monitoring control must maintain the spark for a fixed time

interval that is long enough for ignition.

Main Gas

shut-off

valve train

NC

M

a

in G

a

s

S

hut-O

ff

Va

lve Tr

a

in

Pilot

CAUTION