14

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

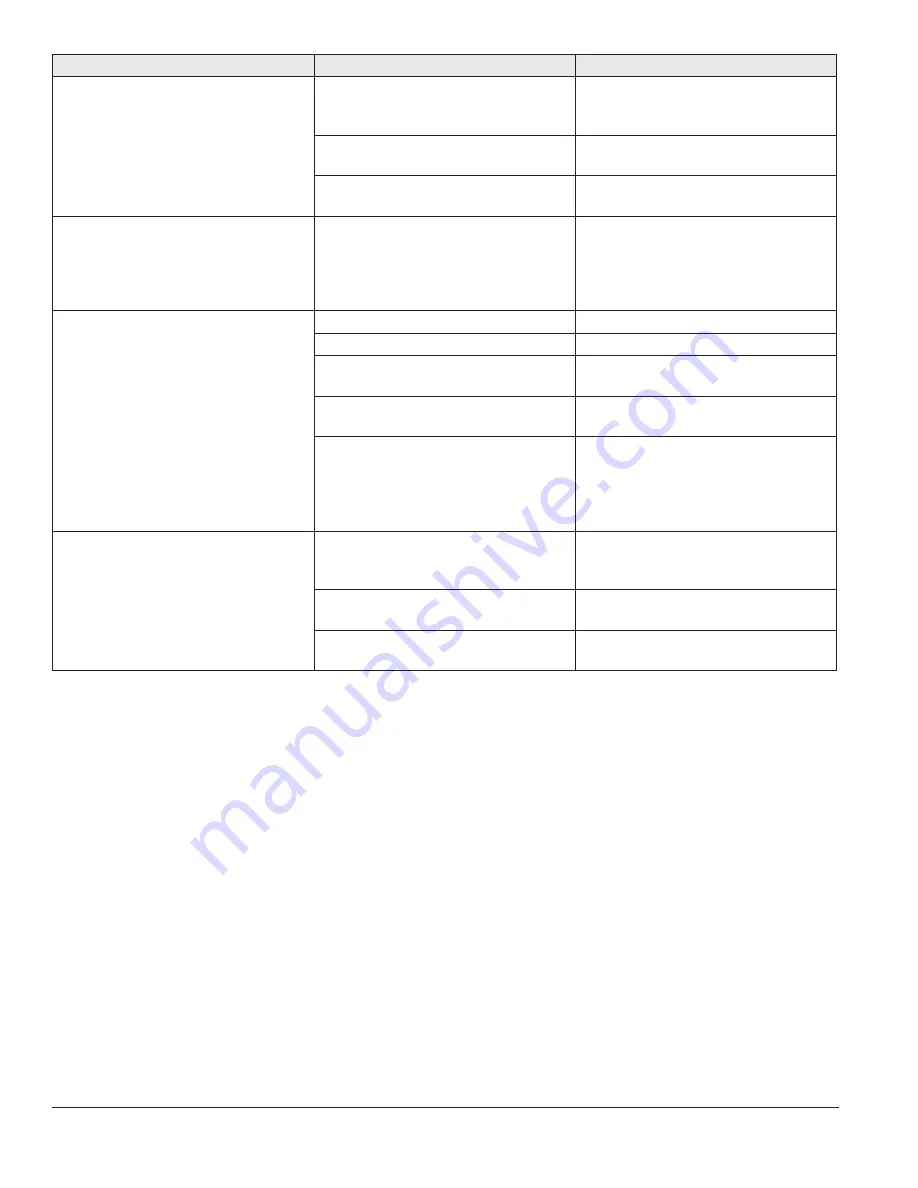

Cannot initiate start sequence

If used, Inlet High Gas Pressure Switch

has activated

Normal operation, when the inlet

pressure drops below the switch

setting, then the system will start.

Motor starter overload tripped

Check for defective motor, reset

overload unit.

Appliance interlock not made or jumper

(continuous operation) is loose

Have qualified electrician verify and

rewire.

Startup sequence runs, but booster

shuts down after several minutes

Booster motor overload, thermal cut-

out switch open

Verify voltage supply, booster motor

rotation direction, sufficient inlet

pressure, and that inlet/outlet valves

are open. Let motor cool and reset

overload.

Cannot achieve full capacity

Inlet/outlet piping too restricted

Rerun larger/straighter pipe runs.

Inlet pressure too low

Consult with utility company.

Booster motor rotation incorrect

Verify and have qualified electrician

rewire.

Manual inlet or outlet valve is partially

closed

Open inlet/outlet valves fully.

Cooling loop control valve too wide

open (MR/MH only)

See OPERATIONAL TESTS in the

COMMISSIONING section. Check

ACT parameters (MH only). Check for

missing or loose coupling, damaged

butterfly valve.

Recirculation loop or heat exchanger

loop is providing insufficient cooling

Actuator settings incorrect,

temperature controller settings

incorrect

Verify Parameters

Butterfly/actuator coupling loose; not

tracking

Check and Reinstall.

Isolation valves not fully open (MH

only)

Open inlet/outlet isolation valves fully.

Problem

Possible Cause

Solution