Exothermics Tubular Heat Recuperators, Installation Guide 545, 3/20/2015

6

Receipt of Heat Recuperator

The heat recuperator should be inspected immediately for

any evidence of damage received in transit. If shipping

damage has occurred, a claim should be filed immediately

with the shipping company. Notify Exothermics, Inc. at

(419) 729-9726.

Installation

The heat recuperator may be installed indoors or outdoors

without the need for additional painting or protection.

Exothermics manufactures three different recuperator

designs: uninsulated, externally insulated, and internally

insulated; each design has it’s own installation

requirements.

Uninsulated Recuperator

All exterior surfaces have the potential to reach elevated

temperatures, therefore, personal protection must be

considered when installing this unit. Because all flange

connections are considered HOT connections, provisions

for expansion are required. Field insulation of the entire

system is recommended.

Externally Insulated Recuperator

These units are typically insulated with 4 to 6 inches

(102 to 152 mm) of insulation to all external surfaces

except the flange connections. The flange connections

and immediate surrounding surfaces, therefore, have the

potential to reach elevated temperatures. Personal

protection must be considered when installing this unit.

Because the flange connections are considered HOT

connections, provisions for expansion are required. Field

insulation of the flanges and surrounding surfaces should

be considered.

Internally Insulated Recuperator

These units are typically pre-insulated with 4 to 6 inches

(102 to 152 mm) of fiber modular insulation. The flange

connections are considered cold connections. Mating

connections must also be cold flanges. External insulation

is not recommended.

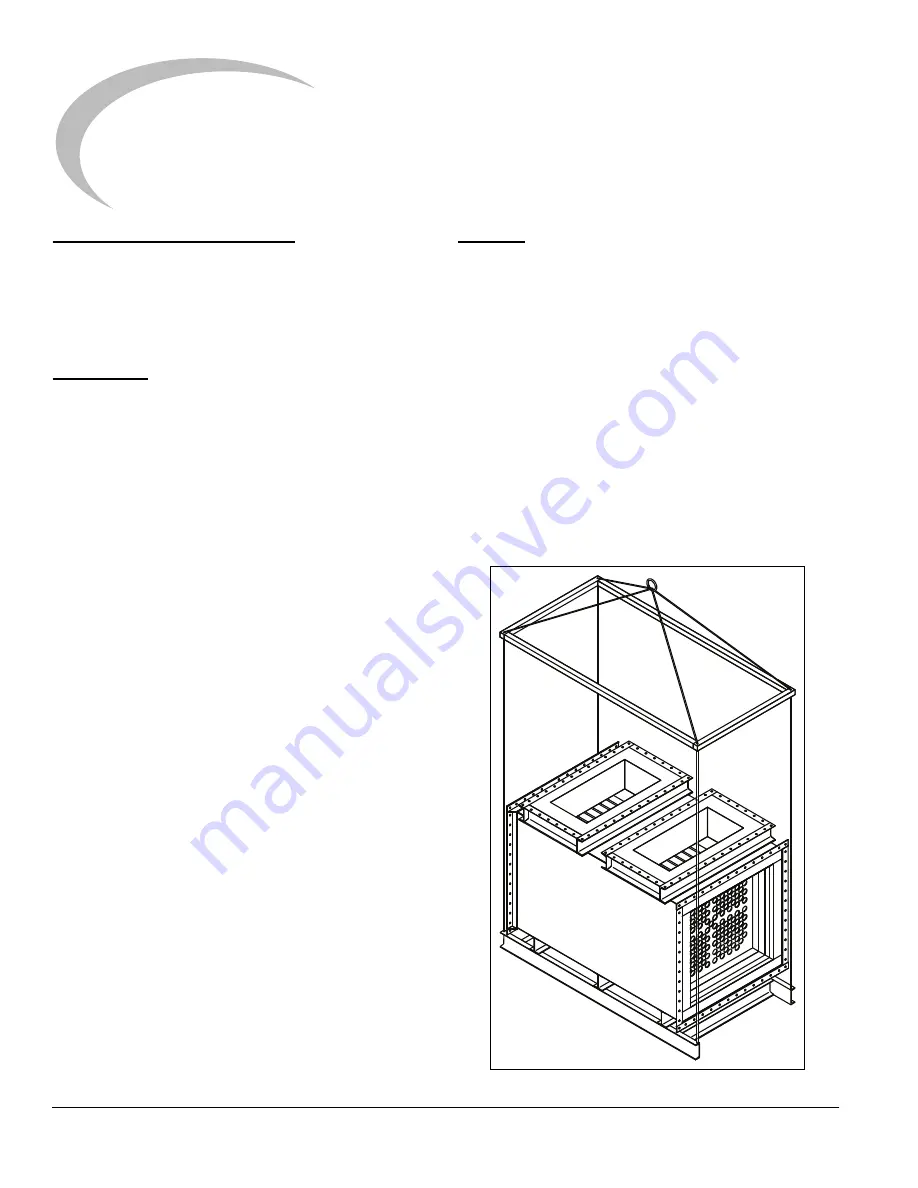

Rigging

When rigging the recuperator for handling by crane,

extreme care should be used to avoid damage to the

recuperator. The heat recuperator is NOT equipped with

lifting lugs. To minimize external loading on the heat

recuperator, a lifting frame should be fabricated from a

minimum of 8 inch (203 mm) channel, the same width and

length as the heat recuperator casing. Lifting slings may

then be attached to the lifting frame. Chains should be

avoided as they may cause external damage. The slings

may then be attached to the I beam supports on the

underside of the heat recuperator. The slings should be

vertical, so that no side loads are transmitted to the heat

recuperator casing or supports. Some units may have

external packaging, plywood covers, or external supports.

This packaging should not be removed until the unit is set

into place.

Figure 3.1.

Installation

3

Summary of Contents for Exothermics Tubular 545

Page 1: ...Exothermics Tubular Heat Recuperators 3 20 2015 Installation Guide 545...

Page 11: ...Notes ii...

Page 12: ......