8

Exothermics Tubular Heat Recuperators, Installation Guide 545, 3/20/2015

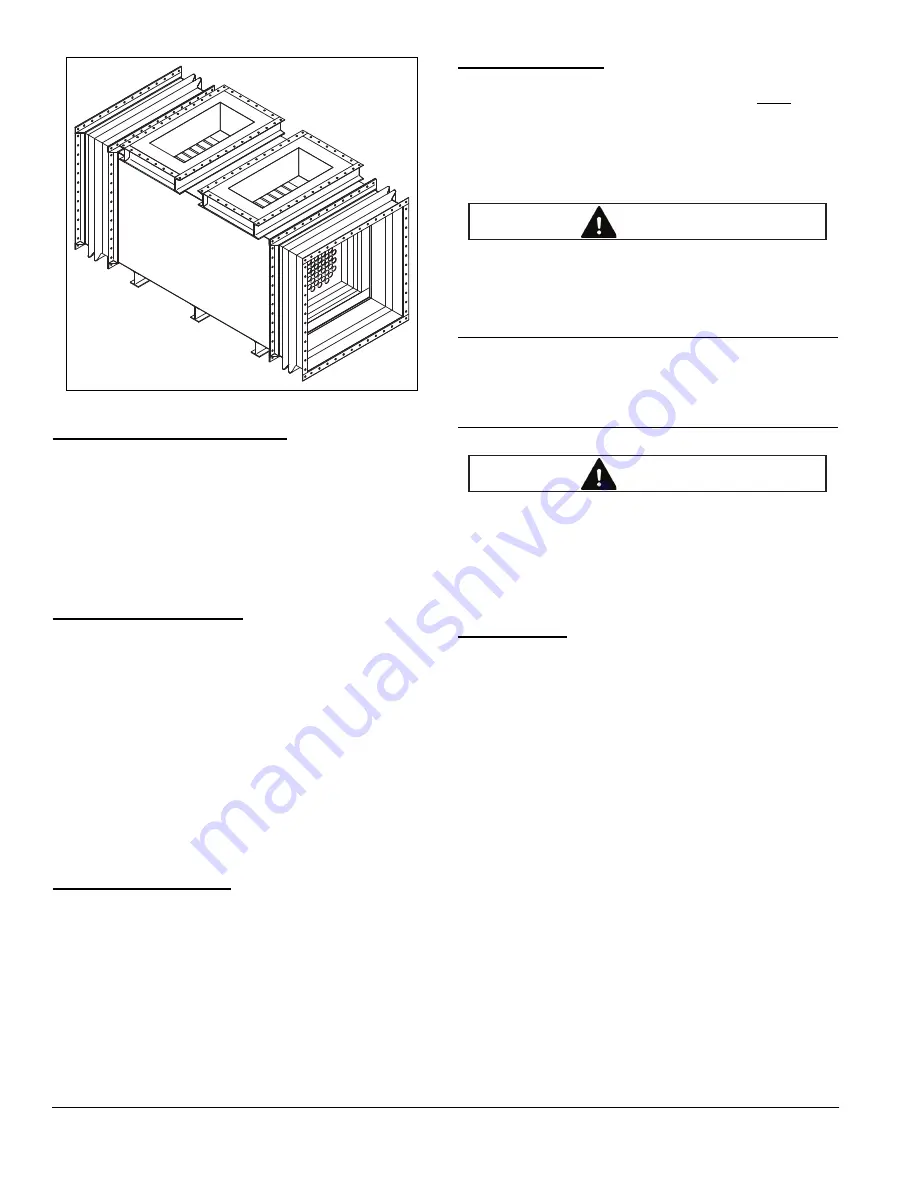

Figure 3.4.

Flange Details and Gaskets

For maximum performance and safety, all flange

connections should be gasketed. A gasket material

appropriate to the operating conditions should be used.

Recommended material is a woven, high temperature

fiber tape. Connections should be made with 3/8 inch (9.5

mm) diameter stainless steel nuts and bolts. All fasteners

should be coated with a high temperature, anti-seize

compound before assembly.

Operation and Startup

Startup should be conducted by qualified personnel in a

systematic manner. Prior to startup, all connections

should be tested for tightness. Flanged connections

should be inspected for leaks. Typically the refractories

used in construction do not require a bake-out or curing

schedule.

Startup personnel should monitor the system closely for

correct operation of temperature controls, high limit

cutoffs, and differential pressure switches prior to release

to operating personnel. It is strongly recommended that

operating personnel be familiarized with the operating

limits of the heat recuperator before use.

Temperature Control

A ramping type temperature control is required. The

maximum rate of heat-up or cool down is 25°F (14°C) per

minute. Exceeding this rate may cause damage to the

heat recuperator due to excessive thermal stress. An

approved high temperature limit control should be

installed in the hot gas inlet airstream. Control and high

limit thermocouples should be placed in the center of the

hot gas inlet duct. All thermocouples should be calibrated

and checked for proper operation before startup.

Excessive thermal cycling should be avoided.

Pressure Control

The maximum rated differential pressure is

w.c.

(mbar). Differential pressure limit switches and controls

are strongly recommended. System fans should be

sequenced appropriately to avoid excessive operating

pressure at startup.

■

The recommended Maximum Continuous

Operating Temperature for the recuperator is:

■

The

recommended

Maximum

Differential

Pressure

for the recuperator is:

■

25°F (14°C) per minute maximum rate of

temperature change.

■

If the recommended operating limits for the

recuperator are exceeded, damage may result.

Maintenance

The tubular recuperator is a high quality, static device with

no moving parts. There are no serviceable user parts

inside. Periodic visual inspection of the tubes is

recommended. The use of a temperature chart recorder

and a high temperature limit control is strongly

recommended.

Thank you for your selection of an Exothermics, Inc. heat

exchanger. If you require additional information or

assistance, please contact your Exothermics

representative or the home office at (419) 729-9726.

CAUTION

CAUTION

Summary of Contents for Exothermics Tubular 545

Page 1: ...Exothermics Tubular Heat Recuperators 3 20 2015 Installation Guide 545...

Page 11: ...Notes ii...

Page 12: ......