4

Eclipse Vortometric Burner, V3, Design Guide 248, 6/10/2010

Introduction

Product Description

The ExtensoHeat is a nozzle-mixing type burner intended

to operate in high-temperature firing kilns with very thick

walls and roof. It is also suitable for special applications in

which the flame must be developed away from the burner.

The ExtensoHeat is designed to inject the flame through

the thick wall in the combustion chamber, discharging a

strong jet of hot gases inside it.

The high speed of the combustion gases ensures

excellent temperature uniformity and high efficiency of the

system, which improves the product quality. The gas

velocity can reach 328 ft/sec (100 m/s). There are different

nozzle lengths ranging from 31 inches (800mm) to 55

inches (1,400mm).

Burner Specifications:

• Control options include on/off or group modulation

and pulse firing. Constant air flow.

• Self ignition by process temperature.

• Flame detection is not necessary (Temperature

above 1382ºF or 750ºC).

• Operability with other fuels.

• Designed to operate with excess gas in chambers

with an oxidizing atmosphere (O

2

> 12% vol.)

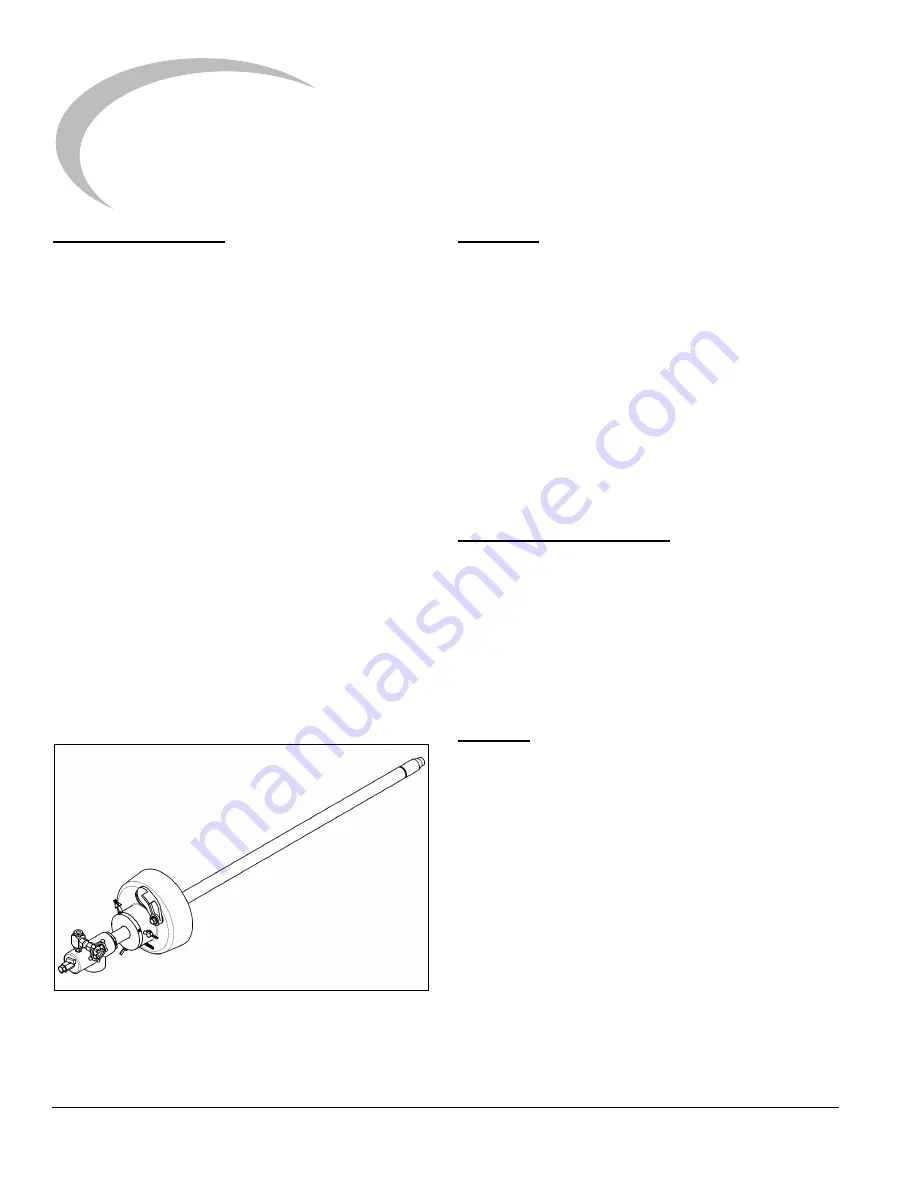

Figure 1.1. ExtensoHeat Burner

Audience

This manual has been written for people who are already

familiar with all aspects of a combustion system and its

add-on components, also referred to as “the burner

system.”

These aspects are:

• Design / Selection

• Installation

• Use

• Maintenance

The audience is expected to have previous experience

with this type of equipment.

ExtensoHeat Documents

Design Guide 235

• Used with Datasheet 235 to design the burner

system

Datasheet 235

• Required to complete design and selection

Installation Guide 235

• This document

Purpose

The purpose of this manual is to ensure the installation of

a safe, effective, and trouble-free combustion system.

1