11

Eclipse TFB, V2, Installation Guide 310, 11/14/2014

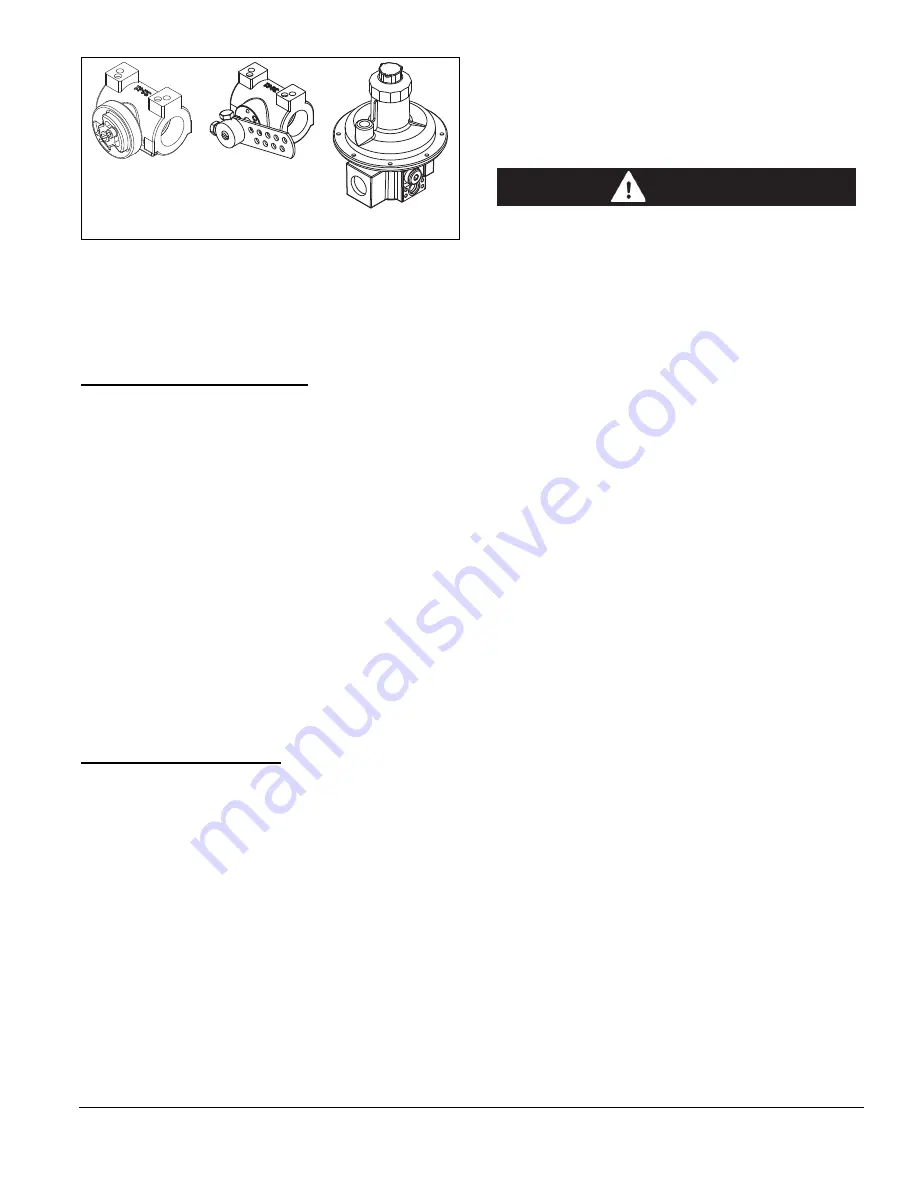

Figure 3.10. Valves

Step 3: Install the Flame Monitoring System

Refer to the System Schematic in Design Guide 310 for

the control methodology used. A detailed explanation of

components can be found in the appendix.

Checklist After Installation

To verify proper system installation, do the following:

1. Ensure that there are no leaks in the gas lines and the

air lines.

2. Ensure all the components of the flame monitoring

control system are properly installed. This includes

verifying that all switches are installed in correct

locations and all wiring, pressure and impulse lines

are properly connected.

3. Ensure components of spark ignition system are

installed and functioning properly.

4. Ensure that the blower rotates in the correct direction.

If incorrect, then have a qualified electrician rewire the

blower to reverse its rotation.

5. Ensure all valves are installed in proper location and

correctly oriented relative to the gas or air flow.

Prepare for Adjustment

After installation of the burner system components are

complete, the following steps should be followed in order

to prepare for adjustment:

1. Set the air pressure switch so that it drops out at 4"

w.c. (10 mbar) below the pressure rating of the blower.

2. Set the low gas pressure switch at 4" w.c. (10 mbar)

below the gas pressure measured at the inlet to the

main gas valve train.

3. Set the high gas pressure switch so that it comes on

at 4" w.c. (10 mbar) above the gas pressure

measured at the inlet to the main gas valve train.

4. Close all the burner gas cocks or pressure taps.

5. Try to light a burner before the purge and other timers

have finished their cycle. Make sure that the flame

monitoring system indicates a flame failure.

6. Trip out pressure switches and other limit interlocks.

Make sure that the main gas valve train closes.

■

If simulated limits or simulated flame failures do

not shut down the fuel system within the required

failure response time, immediately correct the

problem before proceeding.

Manual

Butterfly

Valve

Automatic

Butterfly

Valve

Ratio Regulator

DANGER