11

Eclipse ThermJet Self-Recuperative, V5, Installation Guide 208, 2/4/2013

NOTE:

The inlet gas pressure to the ratio regulator must

be a minimum of 5" w.c. (12.5 mbar) higher than the

impulse line pressure at high fire condition.

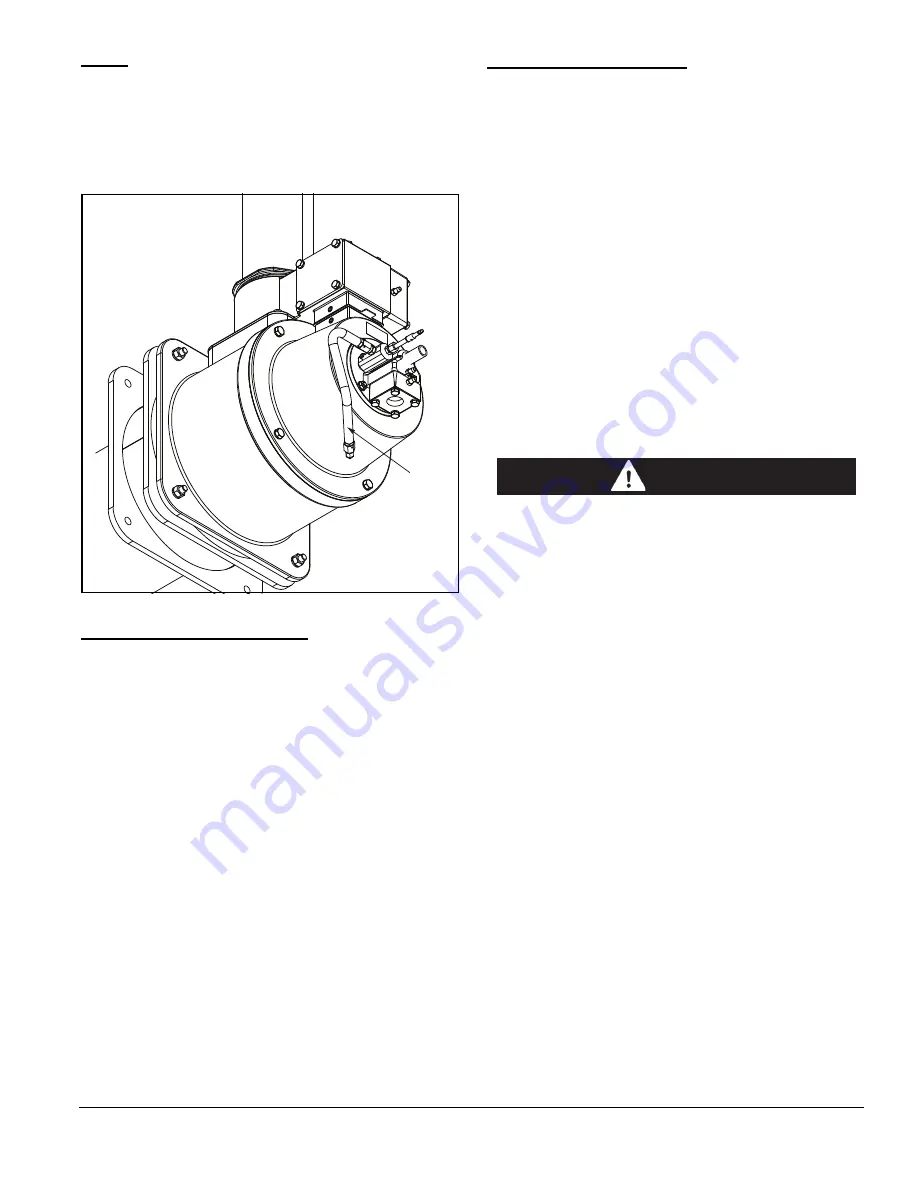

Step 9: Spark Rod Cooling Option

If applicable, connect flex hose to air cooling connections

as shown in Figure 3.13.

Figure 3.13

Checklist After Installation

To verify the system was properly installed, perform the

following checks:

1. Be sure there are no leaks in the gas lines.

2. Be sure all the components contained in the flame

monitoring and control system are properly installed.

This includes verifying that:

• all the switches are installed in the correct locations.

• all wiring, pressure, and impulse lines are properly

connected.

3. Be sure all components of the spark ignition system

are installed and functioning properly.

4. Be sure the blower rotates in the proper direction. If

the rotation is incorrect, have a qualified electrician

rewire the blower to rotate in the proper direction.

5. Be sure all valves are installed in the proper location

and correctly oriented relative to the flow direction.

Prepare for Adjustment

After installation of the burner system components is

complete, the following steps should be followed in order

to prepare for adjustment:

1. Set the air pressure switch so that it drops out at 4"

w.c. (10 mbar) below the pressure rating of the blower.

2. Set the low gas pressure switch at 4" w.c. (10 mbar)

below the gas pressure measured at the inlet to the

main gas valve train.

3. Set the high gas pressure switch so that it comes on

at 4" w.c. (10 mbar) above the gas pressure

measured at the inlet to the main gas valve train.

4. Close all the burner gas cocks.

5. Try to light a burner before the purge and other timers

have finished their cycles. Make sure that the flame

monitoring system indicates a flame failure.

6. Trip out pressure switches and other limit interlocks.

make sure that the main gas valve train closes.

■

If simulated limits or simulated flame failures do

not shut down the fuel system within the required

failure response time, immediately correct the

problem before proceeding.

Flex

Hose

DANGER