Eclipse Winnox Burner, WX Series, V2, Installation Guide 111, 2/26/2010

16

This section is divided into two parts. The first part

describes the maintenance procedures, and the second

part helps you to identify problems that may occur and

gives recommendations on how to solve these problems.

Preventative maintenance is the key to a reliable, safe

and efficient system. The following are suggested

guidelines for periodic maintenance. Burners in severe

environments or operational conditions should be

checked more frequently.

NOTE:

The monthly and yearly lists are an average

interval. If your environment is dirty, then the intervals may

be shorter. Check with local authorities having jurisdiction

on their recommended maintenance schedules.

Ŷ

Turn off the power to the burner and controls

before proceeding with burner inspection.

Monthly Checklist

1. Inspect flame-sensing devices for good condition and

cleanliness.

2. Check for proper air/gas pressures. Refer to the

Winnox datasheet, series 111.

3. Test all alarms for proper signals.

4. Check and clean igniter electrodes.

5. Check the air control valve for smooth, trouble free

operation and adjustment.

6. Check for the proper operation of ventilating

equipment.

7. Test interlock sequence of all safety equipment and

manually make each interlock fail, noting that related

equipment closes or stops as specified by the

manufacturer. Test flame safeguard by manually

shutting off gas to burner.

8. Test all manual fuel valves for operation.

9. Clean and/or replace the combustion air blower filter.

10.Inspect and clean the combustion air blower rotor.

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness of

closure.

2. Test pressure switch settings by checking switch

movements against pressure settings and compare

these with the actual impulse pressure.

3. Visually check ignition cable and connectors.

4. Inspect impulse piping for leaks.

5. Be sure the following components are not damaged or

distorted:

• the burner nozzle

• the igniter

• the flame sensors

• the combustion tube or block

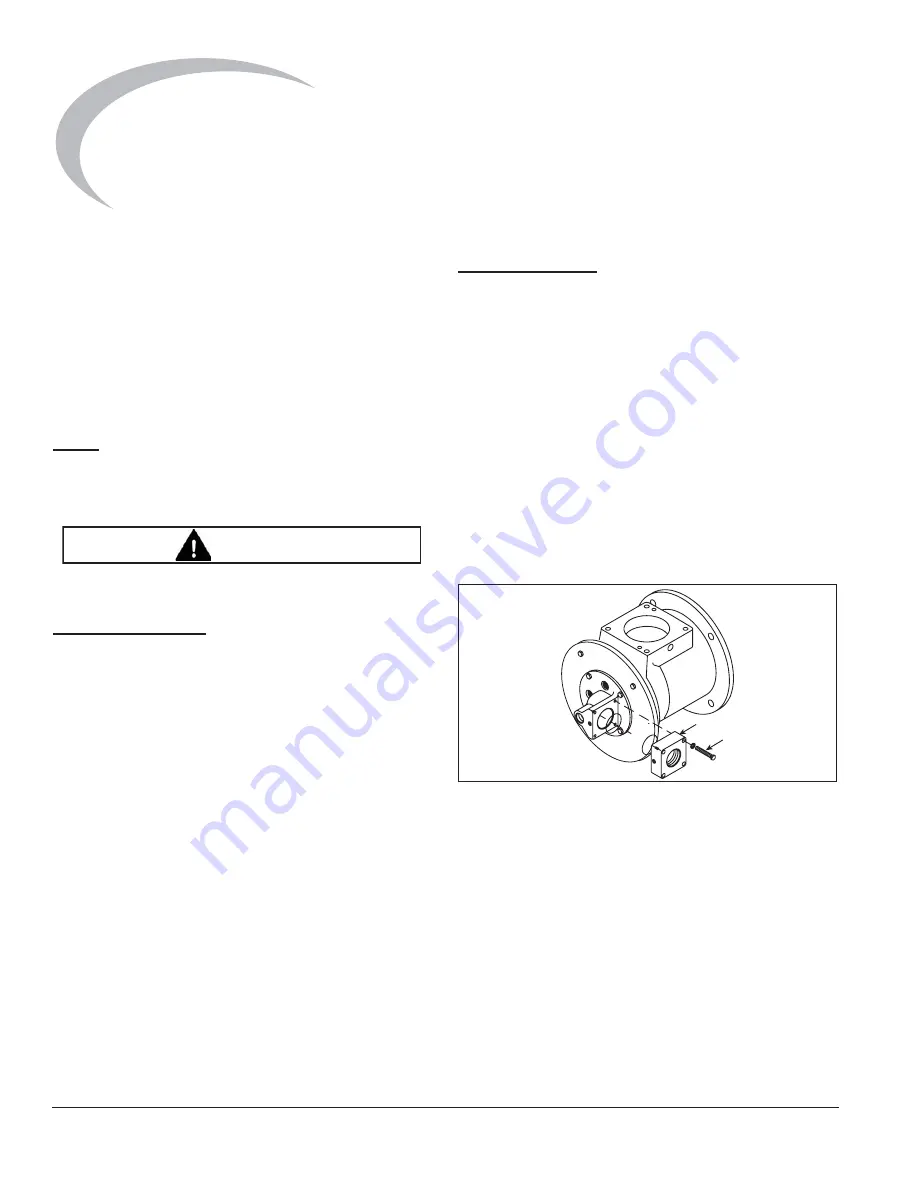

Figure 5.1 Component Inspection

The nozzle can be inspected without removing the burner

from the chamber wall or entering the chamber. See

Figure 5.1 and Figure 5.2. Perform the following:

a. Shut the burner off and manually close the main gas

shut off cocks.

b. Allow the chamber temperature to cool down to

250°F (121°C).

c. Disconnect the gas piping at a union or the gas inlet

flange

X

provided on the burner.

d. Remove the four bolts

Y

.

CAUTION

Maintenance &

Troubleshooting

5