INSTALLATION, OPERATION AND MAINTENANCE MANUAL

6

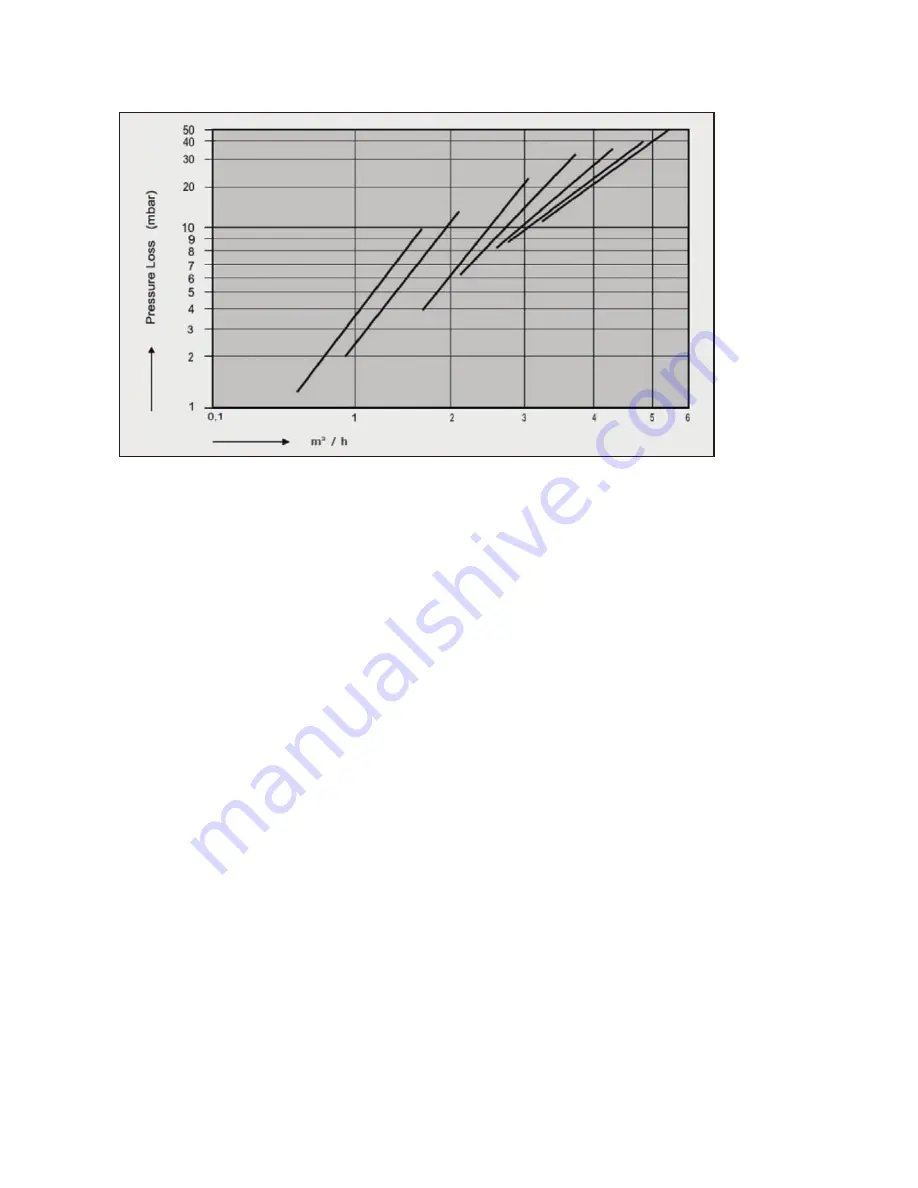

Head losses

fig. 04

Operating instructions

Angus Max Series Boiler – General features

■

Angus Max series solid fuel fired boiler is designed for heating both residential and industrial buildings.

■

Besides professional installation, precondition for correct functioning of the boiler is the required chimney thrust and

correct operation.

■

Angus Max series solid fuel fired boiler is designed for heating systems which are suitable for forced circulation systems only.

■

Angus Max series boilers are available in seven output series (determined by the number of segments 4, 5, 6, 7, 8, 9, 10)

from 38 to 95 kW.

■

The cast iron boiler body comprises of segments and serves as a combustion chamber (including combustion gases routes),

and at the same time as a water reservoir (including water routes). Segments are of three types – front and rear, inserted

between which are 1 to 8 middle segments (of the same kind). By assembling and joining together an appropriate number of

segments, a boiler body of the required size is constructed (both the combustion chamber and the water reservoir). Assembled

boiler body is equipped with necessary pipe sections for water connection. It also has brackets for fitting thermostat sensors

and brackets on feet for fastening the boiler to the base. Attached to the cast iron boiler body are sheet metal covers which

are fitted on the inside with thermal insulation.

■

To ensure that the boiler functions correctly and runs economically, it is important that its nominal output is equal to the thermal

losses of the heated premises.

■

Choosing a boiler of insufficient output will result in inadequate heating of the premises, and thus failure to provide a

heating comfort.

■

Choosing a boiler of unnecessarily high output will result in the boiler not running in full output, and as a consequence in

tarring and dewing.

Recommended fuel

■

Recommended fuels for Angus Max boilers are coal, coke and firewood.

■

Optimal coal and coke granularity is 24-60 mm.

■

Optimal firewood size is logs of diameter 40-100 mm. Their length will depend on how many segments the boiler have.

■

Fuel must be stored in a dry place. To reach the boiler nominal output, water content in firewood must not exceed 20%.

■

Approximate stoking intervals (reffered to as Burning Time) are shown in the Technical Data Table on page 3.

■

The boiler is stoked manually.

Please note

The boiler is not intended for burning any type of waste.