E93.9950EN CB Cascade manual

21

13. Determine managing and depending boilers

Before completing the mechanical installation it is important to decide

which boiler will be the managing boiler.

Any of the boilers can be assigned as managing boiler; all the other boilers in the cascade configuration have to

be assigned as depending boilers.

When the CH supply temperature is based on an outdoor sensor, only one outdoor sensor is needed. This

sensor is connected to the managing boiler and calculates the CH setpoint for the cascade system.

A cascade system can be used with an DHW indirect tank. A DHW circulator and sensor must be connected to

the managing boiler.

All boilers in the cascade system have to be assigned a unique address. This is done in the parameters of each

boiler.

How to assign unique addresses to boilers and how to manage the parameters required for the cascade

configuration is described in detail in the chapter(s) about Cascading in the Installation & Service Manual of the

CB boiler series.

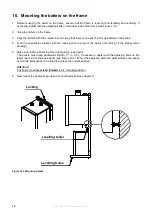

14. Complete the mechanical installation

After the previous instructions have been completed, the cascade configuration must be connected to the

heating system and the mechanical installation of the cascade configuration must be completed with all other

necessary parts and connections.

This may include:

•

all valves

•

non-return valves

•

strainers

•

air separators

•

expansion vessel

•

overflow

Attention!

The hydraulic piping of the Eco Heating Systems cascade systems already contains non-return valves

underneath each boiler. When other hydraulic systems are used, non-return valves must be fitted in the return

pipe of each boiler.

The Installation & Service Manual of the CB boiler series provides you with the necessary installation schemes

and requirements to complete the installation.

In addition to the instructions from the Installation & Service Manual, it is imperative for the cascade configura-

tion to:

•

Complete all wiring of the boilers according to the boiler manual. For the system to work for cascade the

communication busses must be parallel linked together.

Attention!

Link all connections 10 to 10 and all connections 11 to 11, do not mix these.

Link connections 10 of the dependent boilers to 20 of the managing boiler, and connections 11 of the

dependent boilers to 21 of the managing boiler.

For more information refer to the chapters on Electrical Installation and Cascade in the Installation & Service

Manual of the CB boiler series.

•

If no expansion vessel or overflow is fitted to the T-connection of the supply connecting set and/or return

connecting set, the T-connection(s) must be blocked by fitting a cap or stopper on the T-connection(s) in

question.