20

©2009 Eco-Orlan USA LLC. All Rights

Reserved

.

Revised August 2009.

26. Disposal and Recycling of Boiler Components

Paxo® boilers contain steel, electronic components, insulation and other materials that may be subject to local, state or federal

regulations as to their proper disposal. When retiring your boiler from service, make sure that all applicable laws, rules and regulations

are observed. When in doubt, check with your local regulating authority for scrapping and disposal guidelines.

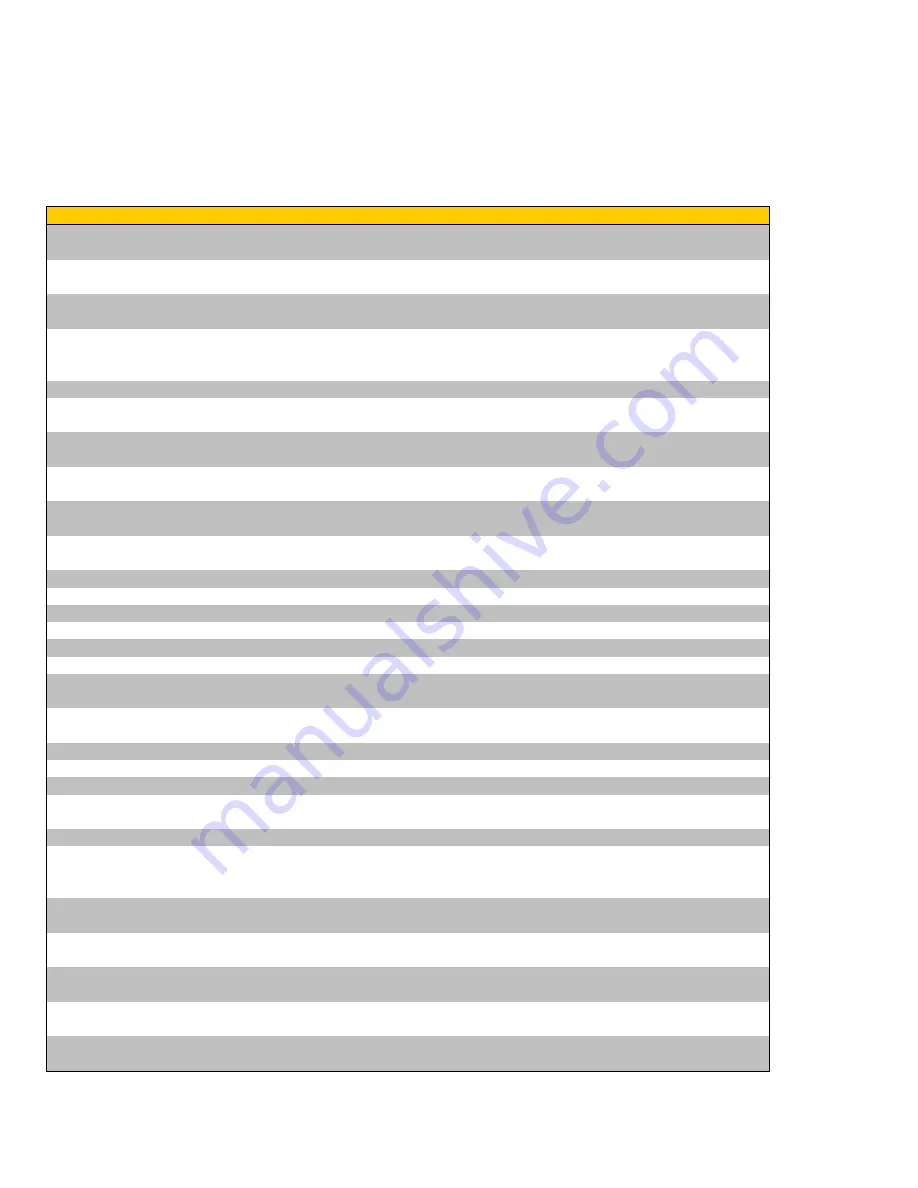

27. Troubleshooting Table

Problem

Probable Cause

Suggested Solution

Smoke comes out of

the cleaning cover

Leak on a seal rope

Repair/replace rope or call service-

not covered by warranty

Seal rope warn

Rope’s replacement -

not covered by warranty

Cover warped –

overheating

Replace cover -

not covered by warranty

Smoke comes out while

loading (a little smoke is

acceptable)

Strong wind blows

the smoke

back into the chimney

Consider installing a special chimney cap –

not covered by warranty

Inadequate chimney

Consult a chimney maintenance professional

Smoke comes out of the

loading door when closed

Leak on a seal rope

Adjust the door hinge

Seal rope worn

Replace rope or call service –

not covered by warranty

Boiler doesn’t reach the

temperature needed

Wood too moist

Use properly seasoned wood

Primary or secondary air

conduit choked

Call service –

not covered by warranty

Wrong regulation of the air

and wood gas

Call service – not covered by warranty

Nozzle damaged

Replacement part – not covered by warranty

Fan’s gasket damaged

Replacement part – not covered by warranty

Fan damaged

Replacement part – not covered by warranty

Regulator doesn’t work

No power

Check the wiring and circuit breakers

Fuse damaged

Replace fuse – not covered by warranty

Live wire conduit damaged

Inspect and repair wire

Regulator or temperature

sensor damaged

Call service

Blower fan

doesn’t work

Thermal protection

engages

Investigate reasons for boiler overheating

No power in regulator

Check fuse and wiring

Fan/ regulator damaged

Call service

Fan blocked

Inspect and clean the fan

Blower fan makes noise

Bearings damaged

Condenser damaged

Call service – fan replacement

Fan clips loosened

Check, tighten the clips

Fan blades dirty

Debris in fan cover

Clean and check

Blower fan works poorly

Dirty fan blades

Creosote on the fan cover

Clean and check

Explosion or puffing in the

firebox

Chimney draft too low

(below 0.40”wc)

Rebuild chimney. Consider use of WKO exhaust fan

Chimney draft too

intensive (over 0.80”wc)

Use exhaust regulator

Wood too small and too

dry

Mix with larger fuel to increase moisture content-

should be between 15-35%

Clogged heat exchanger

tubes

Clean the exchanger or call service –

not covered by warranty