4

©2009 Eco-Orlan USA LLC. All Rights

Reserved

.

Revised August 2009.

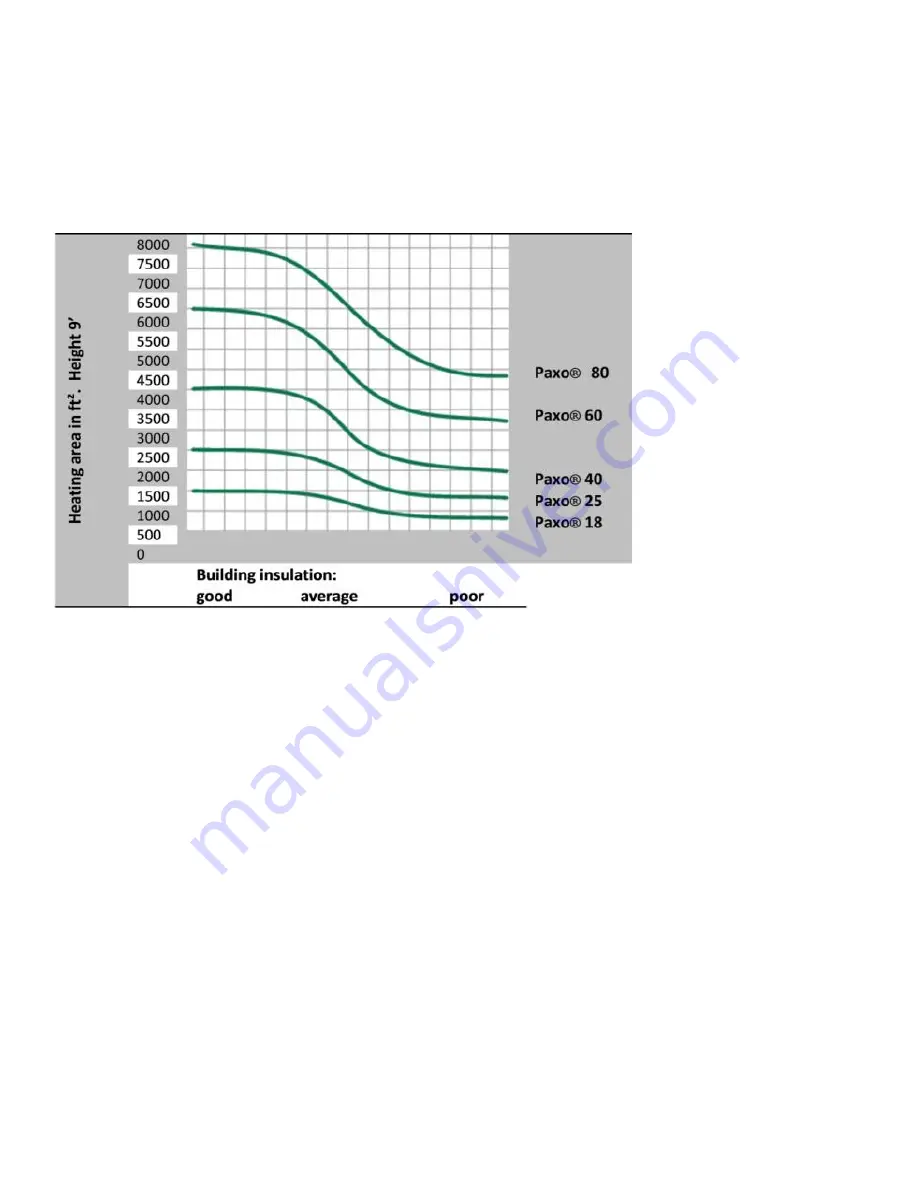

3. System Design Considerations and Sizing of the Boiler

It is critical to size the Paxo® boiler properly. A proper up to date heat load calculation is strongly advised. An accurate history of

the building’s fuel usage over several years can help calculate the proper size boiler. Be wary of simple techniques based only on

square footage. The heat load of a home can vary widely depending on the age, type of heating system, and geographical location of

the home. The manufacturer provides published data for the unit; however, this cannot be your sole source of information either for

sizing your system. The purchaser must use actual measurements made at the premises of where the unit will be installed and

operating. Eco-Orlan USA LLC and all of its Authorized Dealers recommend consultation and sizing by a licensed professional

trained in HVAC systems with proper licensing credentials appropriate for the State or Province in which the unit is to be installed.

Final sizing of the unit is the sole responsibility of the purchaser.

4. Wood and the Gasification Process

Quality, moisture content and type of burned wood are very important. Hardwood is the best (beech, oak, hickory, maple etc.) The

maximum moisture content of the wood used to fuel the boiler should be between 15% and 20%. Using dry softwood, such as pine,

spruce etc. is possible but it will burn faster and require more frequent loading of the boiler than if hardwood is used.

Wood’s moisture content can be determined with a moisture meter. As a general rule, hardwood stacked for one year under cover is

usually ready for use as a fuel in the Paxo® boiler. Wood that has been properly stored for two years is the best.

Wood is a fuel which can be stocked and stored with no energy loss. Storing wood lowers its moisture and raises its heating value.

Wood is also the only combustion fuel that doesn’t contribute carbon dioxide which means that during the growth and photosynthesis

process it takes in the same quantity of carbon dioxide that it emits during the combustion process. Modern wood gasification boilers

utilize wood’s energy at efficiency three times higher than ordinary boilers and they operate similar to gas boilers. A

Paxo

® wood

boiler is adapted for combustion of various sizes of wood granulation from sawdust to large pieces. Shavings, cuttings and slivers

should be combusted with larger pieces of wood. Spring is usually the best time for buying wood (wood from winter tree clearance).

During the heating season 1 cord of wood is generally needed for heating of 200 square feet.

5. Heat Storage Tank

Designed for Optimum performance of the Paxo® gasification boiler, we strongly recommend the use of hot water storage when

operating your Paxo® gasification boiler. We recommend 50 liters or 13.23 Gallons of water storage per kilowatt as minimum size

hot water storage. Properly installing a Heat Storage Tank can cut your wood consumption by as much as 40%. Hot water storage

allows the boiler to run at ideal capacity regardless of the demand for heat from the building being heated. This enables you to

continue to heat your home most efficiently throughout the warmer times of the year such as early spring and late fall. It also provides

the flexibility to heat your domestic hot water in the summer season.