5

©2009 Eco-Orlan USA LLC. All Rights

Reserved

.

Revised August 2009.

6.

Gasification

wood burned in gasification boilers gives almost three times more heat than

ordinary boilers or chimneys

nearly zero balance of CO2 because the amount of carbon dioxide in emissions is very close to the amount of the CO2 gas

consumed with the plants growth

the content of the emissions from a wood gasification boiler is nearly the same as the emissions of gas boiler

wood combustion at up to 2000°F (pyrolisys- dry wood distillation) greatly limits the amount of the harmful components in

the emissions

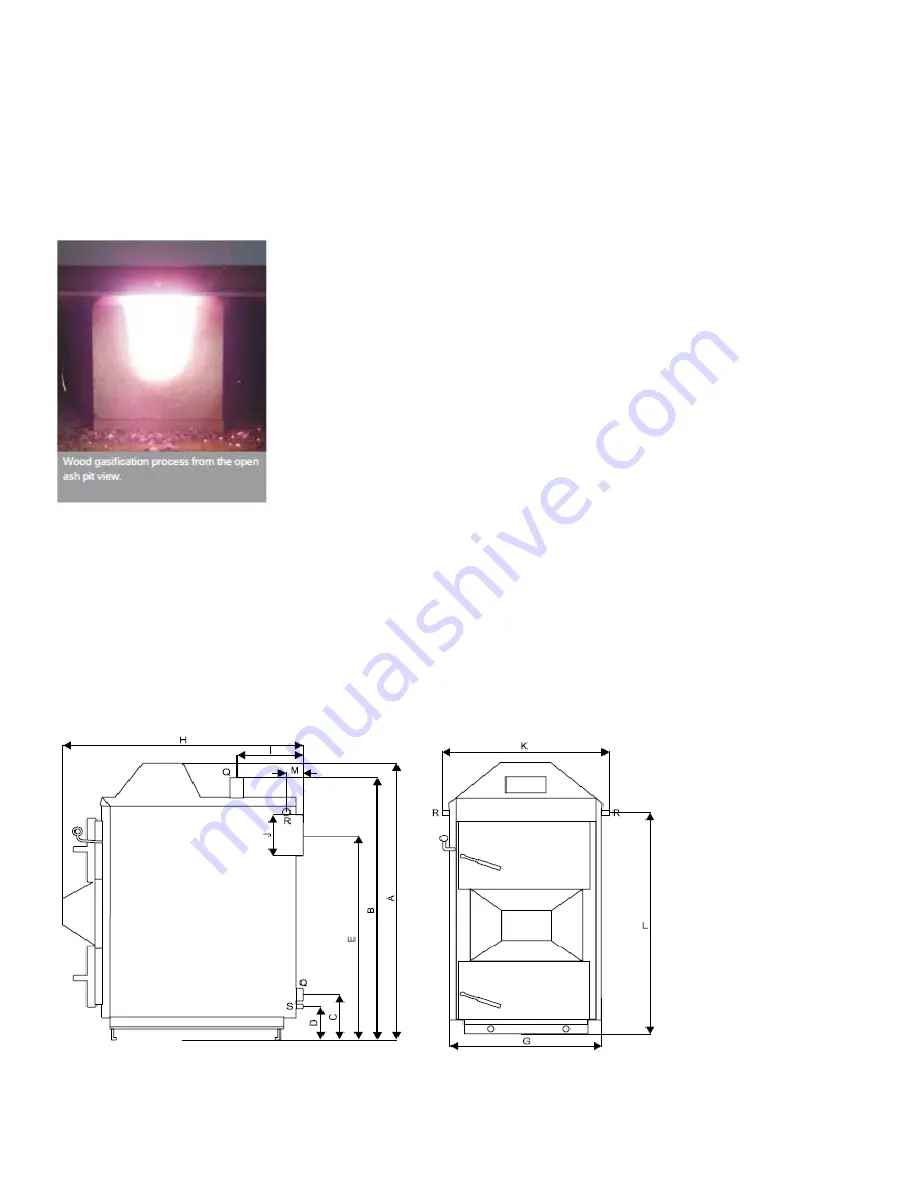

Dry wood is burned in the (top) primary combustion chamber, where heat from the flame breaks the wood structure down into

charcoal and then into combustible gas. This gas passes through the ceramic nozzle (or nozzles, depending on the model) at the

bottom of the primary combustion chamber, where it is mixed with superheated air and burned cleanly at high temperatures (up to

2000°F) in the refractory-lined bottom chamber. This clean-burning flame produces little or no smoke. This hot gas then exits the

boiler through the heat exchanger tubes and into the chimney.

Gas which was 2000°F in the secondary chamber is typically only 300 to 400°F when it reaches the chimney, meaning that 1,600 to

1,700°F is being transferred into the hot water jacket through the heat exchanger tubes.

7. Technical Data