8

©2009 Eco-Orlan USA LLC. All Rights

Reserved

.

Revised August 2009.

9. Installation

Paxo ® wood boilers are designed to conform to and be installed in accordance with the very strict European regulations. The

requirements are known as norm PN 87/B 02411 and norm PN 91/B 02411.

When installed in the United States, all applicable local codes and regulations apply.

Boiler Type

unit Paxo

®

18

Paxo

®

25

Paxo

®

40

Paxo

®

60

Paxo

®

80

Chimney flue draught

Pa

15-20 Pa = .06-.08 inches of water

Electric protection range

IP 40

Maximum working pressure

PSI

25

Average fumes temperature

°F

464

340

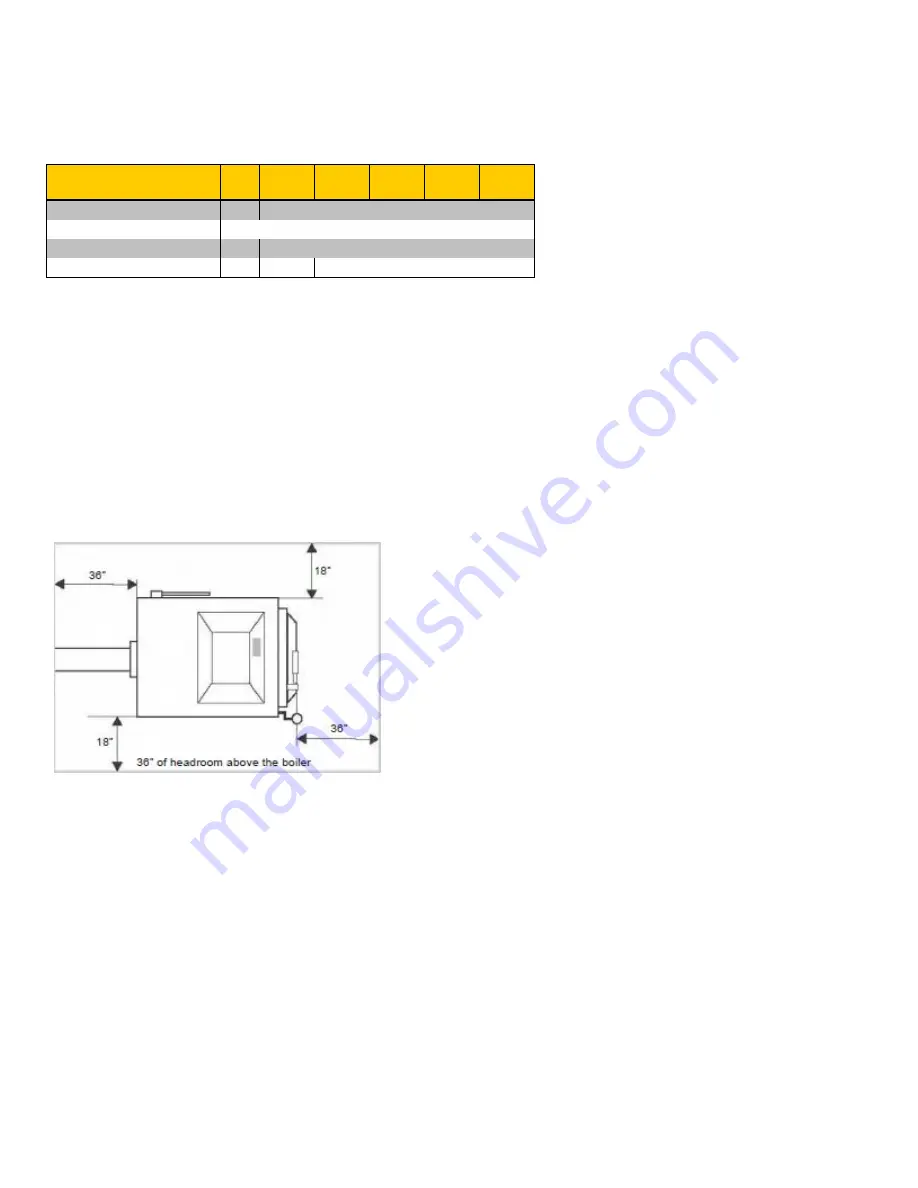

10. Location

The boiler must be located on a level concrete floor or on a similar non-flammable surface.

Wood gasification boilers are heavy. Make sure to consider the weight when planning the installation.

The boiler can be placed in a utility room, basement or outbuilding, along with wood storage. Putting the boiler in an outside location

is recommended for easy access to wood storage.

Adequate space around the boiler is needed for installation, operation, cleaning and maintenance. Enough space is needed for loading

the boiler and emptying the ash bin. The distance between the boiler and the surrounding walls should be sufficient to allow access to

all of the boiler’s parts. The boiler must be positioned to provide minimal clearances from combustibles and surfaces: left and right

side = 18”, top, rear and front = 36”.

If the boiler is placed near inhabited rooms, so that the flue gas can easily penetrate into these rooms, a carbon monoxide alarm must

be installed that can give a warning regarding possible escapes of carbon monoxide into the inhabited rooms.

As an additional precautionary measure the boiler must not be installed in an area, room or outbuilding where there are flammable

liquids or combustibles. Examples include: refrigerants, paint thinner, bleach etc. It is also strongly recommended that a certified Fire

Extinguisher is mounted in proximity to the boiler.

11. Chimney Specifications

The chimney or flue is one of the most critical factors in the successful operation of any solid fuel heater, including the Paxo® boiler.

A good chimney will provide a continuous and dependable draft to pull the exhaust gases out of your boiler. The boiler must be

connected to a tile-lined masonry flue or to a Type HT approved chimney. Minimum required flue size is 8”x8” with square tile or 8”

diameter round tile or stainless steel. No other appliance should be connected to this flue. The boiler should be connected to the flue

with the shortest, most direct run of black stove pipe. Maintain a minimum of 18” between the flue pipe and combustion surfaces.

Prior to operation, the installation should be inspected and approved by qualified professionals (for example; a chimney sweep, a

licensed plumbing and heating technician, an electrician). The chimney and the connecting pipe need to be insulated for safety and to

prevent condensation and a reduction in the draft caused when the gas in the chimney cools down too much. If there is still a problem

with draft (too much or too little), you may need to consider draft inducing fans or draft regulators may need to be considered.