pag.8

B

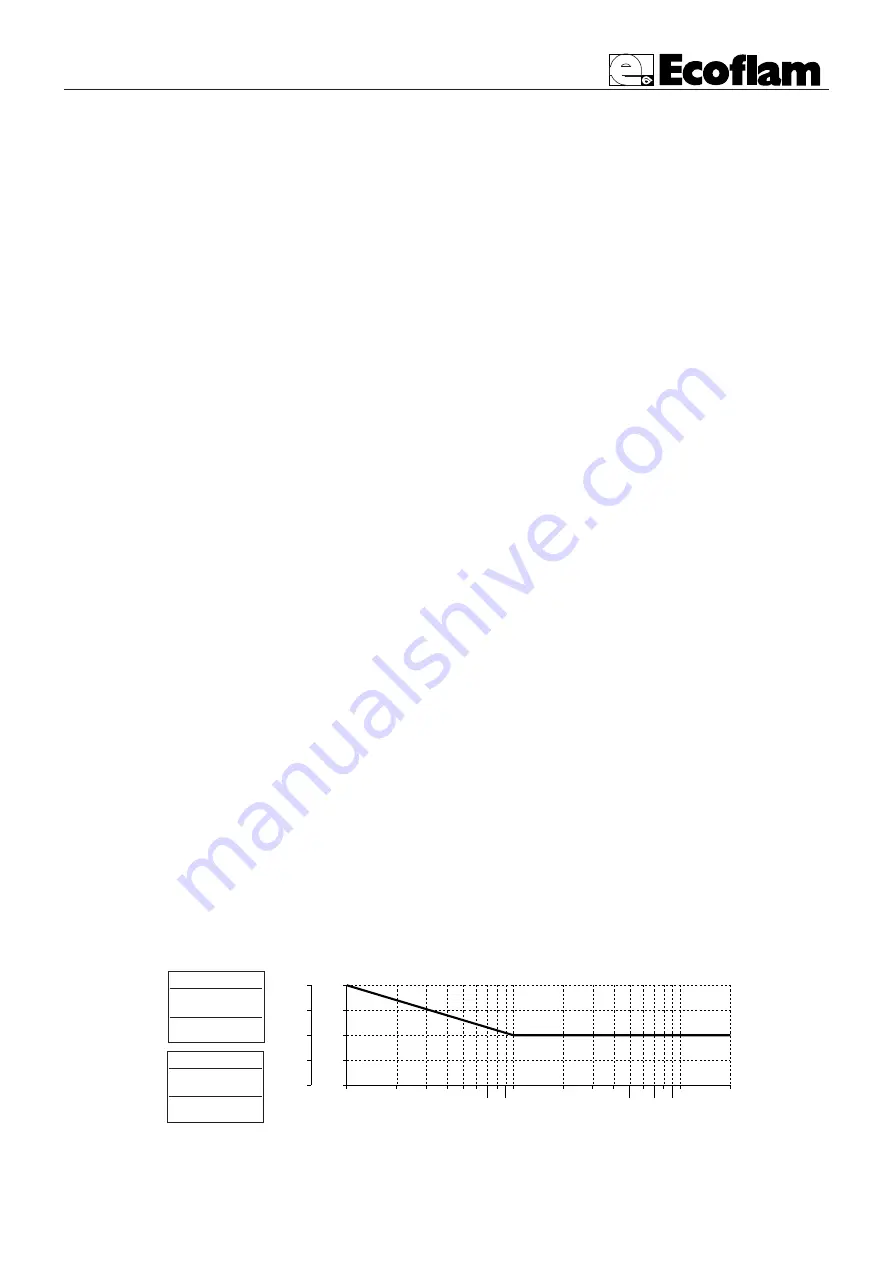

LB 447

Blu 500 ÷ 700 P

AIR

EXCESS

(%)

AIR

FACTOR

10

10

20

30

40 50 60

70

80

90

100

200

300 400

500

600

700

800

900

1000

2000

1,1

1,15

1,2

1,2

1,2

1,25

1,3

15

20

25

30

THERMAL POWER (kW)

Metano

CO

2

9,6%

CO

<50 ppm

G.P.L.

CO

2

11,7%

CO

<50 ppm

ADJUSTING THE COMBUSTION

WARNING:

in order to adjust combustion and thermal capacity correctly, the fumes must be analyzed using specific instruments.

Combustion and thermal capacity must be adjusted simultaneously, making sure that the values read are correct and in any

case, that they comply with the safety regulations in force.

THIS OPERATION MUST BE PERFORMED BY PERSONNEL WHO ARE PROFESSIONALLY QUALIFIED

AND AUTHORIZED BY ECOFLAM SPA.

ELECTRICAL CONNECTIONS

All burners factory tested at 400 V 50 Hz three-phase for motors and 230 V 50 Hz monophase with neutral for auxi-

liary equipment. If mains supply is 230 V 50 Hz threephase withuot neutral, change position of connectors on burner

as in fig. Protect burner supply line with safety fuses and any other devices required by safety standards obtaining in the

country in question.

CONNECTION TO THE GAS PIPELINE

Once connected the burner to the gas pipeline, it is necessary to control that this last is perfectly sealed. Also verify that

the chimney is not obstructed. Open the gas cock and carefully bleed the piping through the pressure gauge connector,

then check the pressure value trough a suitable gauge. Power on the system and adjust the thermostats to the desired

temperature. When thermostats close, the sealing control device runs a seal test of valves; at the end of the test the bur-

ner will be enabled to run the start-up sequence.

START UP OF THE BURNER

PRELIMINARY CHECKS

Before starting up the boiler check the following:

• gas type and feed pressure;

• gas valves closed;

• the seals in the pipe fittings;

• gas pipe breather and input pressure;

• that the cable complies with the diagram and the phase and neutral wires correspond;

• that the burner shuts down when the boiler thermostat opens

• the seal of the boiler furnace which prevents air from entering

• the seal on the flue-boiler pipe fitting;

• the condition of the flue (sealed, free from blockage, etc.).

If all these conditions are present, start the burner. The control device starts the motor to carry out prewashing of the

combustion chamber. During this prewash period (about 30 seconds) the device checks that air pressure is correct via

the air pressure switch. At the end, it supplies power to the transformer and opens the gas valves. The flame must be lit

and stabilize within 3 seconds, which is the device's safety time limit. Check to ensure the flame is lit before placing any

control instrument in the flue. Adjust and check the gas flow necessary for the boiler at the meter. Adjust the air flow

according to the gas flow to obtain correct combustion.

IMPORTANT ADVICE

All adjustable parts must be fixed by the installer after making adjustments. Check flue combustion after each adjust-

ment. The CO

2

values must be approx. 9.7 (G20) 9.6 (G25 11.7 (l3B) 11.7 (l3P) and the CO must be less than 75

ppm.