Once having installed the burner, check the following items:

- The burner power feeding and the main line protection fuses

- The correct length of pipes and that the same are sealed.

- The type of fuel, which must be suitable for burner.

- The connection of boiler’s thermostats and all the safeties.

- The motor rotation direction.

- The correct calibration of the motor’s thermal protection.

When all the above mentioned conditions are checked and accomplished, it is possible to go on with burner’s

tests. Power the burner. The control box feeds the ignition transformer and the burner’s motor at the same

time, which will run a prepurging of the combustion chamber for about 20 sec.

At the end of prepurging, the control box opens the fuel pump and the 1st stage (Low flame) solenoid valves,

the ignition transformer produces a spark and the burner ignites. After a safety interval of 5 seconds and a

correct ignition, the control box turns off the ignition transformer and, 10 seconds later, sets the motorised

air damper to its maximum opening and opens the 2nd stage solenoid valve (High flame). In case of faulty

ignition, the control box switches the burner into safety condition. In such a case, the manual rearming of the

burner shall not take place before 30 seconds have elapsed from the burner’s safety shutdown. In order to

obtain an optimal combustion, it is necessary adjust the LOW - HIGH flame air flow, according to the

instruction given further on. During such a phase, it will be possible to manually switch between HIGH ( II )

and LOW ( I ) flame and viceversa, through the High/Low flame switch. At the end of the adjusting phase,

leave the switch in position II (HIGH flame).

The fuel pump feeding pressure, must remain around 12 bar.

BURNER START-UP AND ADJUSTMENT

A

MIN

MAX

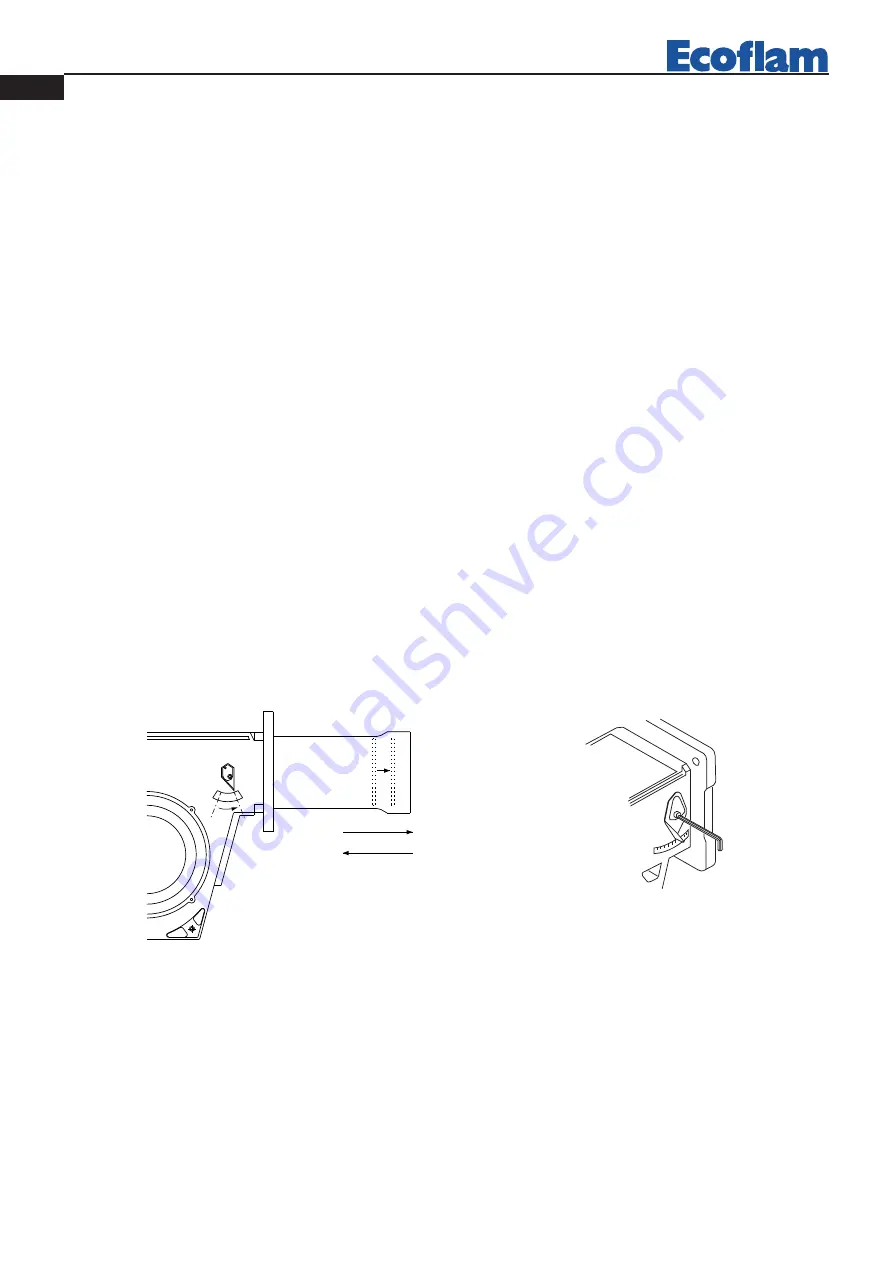

FIRING HEAD SETTING

A

420010259702

Maior P 60 AB HS

EN

12