LB 1681

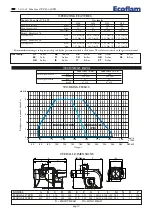

Max Gas 170 PR - 250 PR

B

pag.17

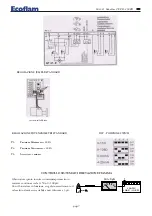

MAINTENANCE

YEARLY INSPECTION

Periodic inspection of the burner (combustion head, electrodes, etc.) must be carried out by authorised per-

sonnel once or twice a year, depending of use. Before carrying out maintenance inspection on the burner, it

is advisable to check its general condition and carry out the following operations:

- Disconnect the burner from the power supply (remove the plug).

- Close the gas cock.

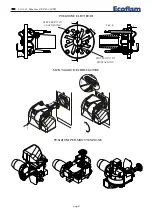

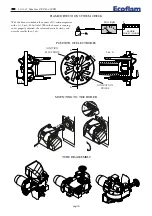

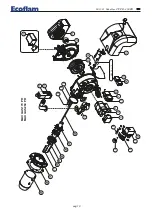

- Remove the burner cover, clean the fan and air intake.

- Clean the combustion head and check the position of the electrodes.

- Re-assemble the parts.

- Check the seal on the gas pipe fittings.

- Check the flue.

- Restart the burner.

- Check the combustion parameters (CO

2

= 9.5 to 9.8),(CO = less than 75 ppm)

BEFORE EACH INTERVENTION CHECK;

- That the system is supplied with power and the burner connected.

- That the gas pressure is correct and the gas cock open.

- That the control systems are correctly connected.

If all these conditions are present, start the burner by pressing the release button. Check the burner cycle.

THE BURNER WILL NOT START;

- Check the switch, thermostats, motor, gas pressure.

THE BURNER PREVENTILATES AND LOCKS AT THE END OF THE CYCLE:

- Check the air pressure and fan.

- Check the air pressure switch.

THE BURNER PREVENTILATES AND WILL NOT IGNITE:

- Check the assembly and position of electrodes.

- Check the ignition cable.

- Check the ignition transformer.

- Check the safety devices.

THE BURNER STARTS UP AND LOCKS AFTER THE SAFETY TIME LIMIT:

- Check that the phase and neutral wires are correctly connected.

- Check the gas electrovalves.

- Check the position of the detection electrode and its connection.

- Check the detection electrode.

- Check the safety devices.

THE BURNER STARTS UP AND LOCKS AFTER RUNNING FOR A FEW MINUTES.

- Check the pressure regulator and the gas filter.

- Check the gas pressure with an ammeter.

- Check the detection value (min 3 µA Landis).